Analysis method for measuring carbohydrate composition of polysaccharide

An analytical method and technology for sugar components, which are applied in analytical materials, measuring devices, material separation, etc., can solve the problems of difficult quantitative analysis, poor separation effect, low sensitivity, etc., and achieve the effects of high content, easy operation and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

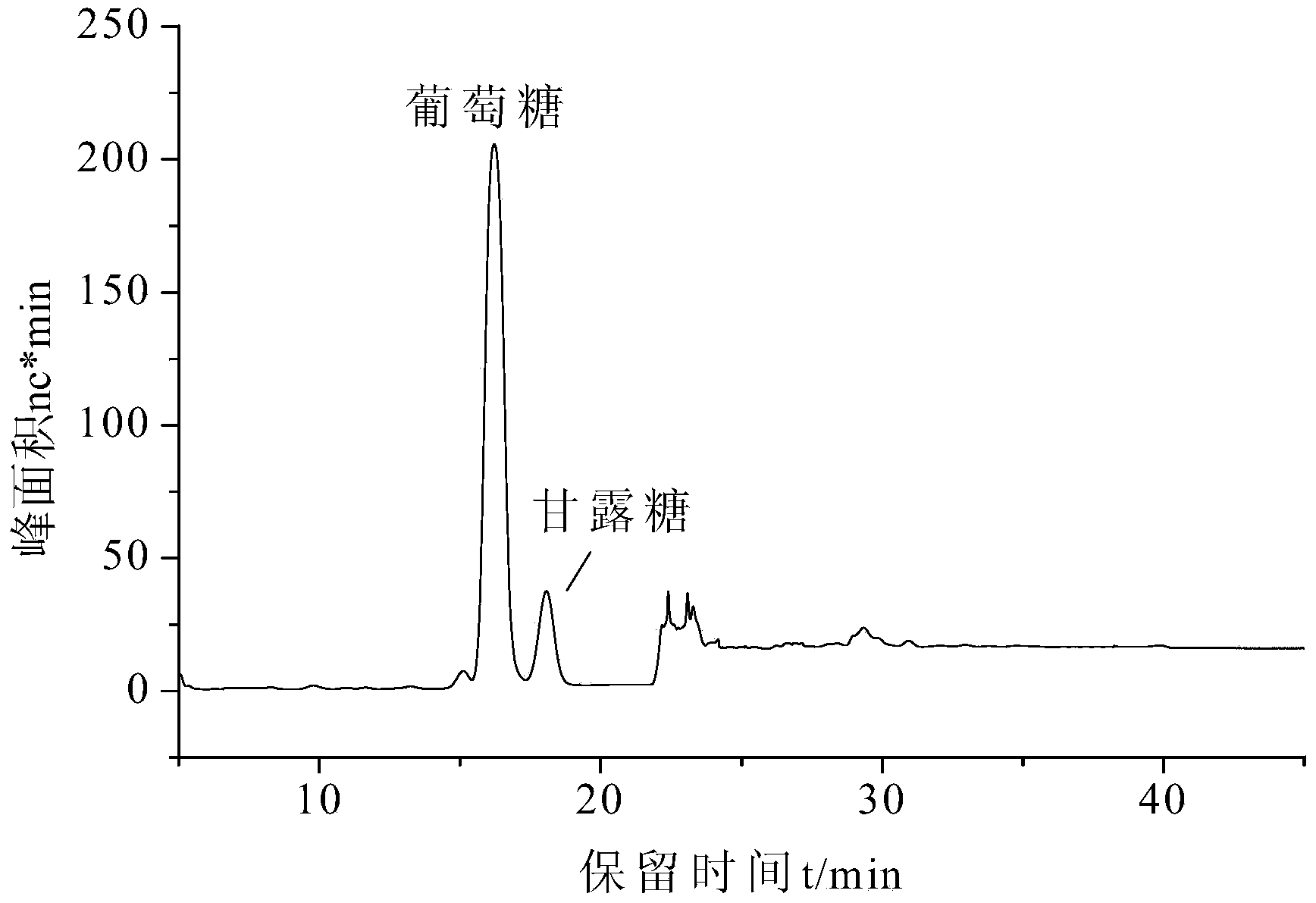

Image

Examples

Embodiment 1

[0037] A method for measuring polysaccharide sugar components, the specific steps are as follows:

[0038] 1. Ionic liquid pretreatment and polysaccharide regeneration: Weigh 0.2g of yeast β-glucan dried in a vacuum oven at 70°C with a vacuum degree of 0.098kPa for 2h at a constant temperature, mix it with 4g of regeneration solvent [BMIM]Cl in oil Fully dissolve in the bath for 2 hours to obtain yeast β-glucan solution; add yeast β-glucan solution to 5 times the volume of ionic liquid in absolute ethanol for regeneration, rinse repeatedly, and centrifugally settle to obtain regenerated yeast β-glucan - Crude glucan product, place the crude product of regenerated yeast β-glucan in a fume hood to fully volatilize the regeneration solvent, and then dry it for 5 hours in an environment with a temperature of 50°C and a vacuum of 0.1KPa to obtain the regenerated yeast β-glucan sugar;

[0039] 2. Hydrolysis with acid solvent: mix the regenerated yeast β-glucan obtained in step 1 wi...

Embodiment 2

[0045] A method for measuring polysaccharide sugar components, the specific steps are as follows:

[0046] 1. Ionic liquid pretreatment and polysaccharide regeneration: Weigh 0.2g of Cordyceps polysaccharide that was dried at a constant temperature in a vacuum oven with a vacuum degree of 0.098kPa at 50°C for 3h, mix it with 3g of regeneration solvent [Emim]Ac in an oil bath and fully Dissolve for 3 hours to obtain a solution of Cordyceps polysaccharide; add the solution of Cordyceps polysaccharide to deionized water with 10 times the volume of ionic liquid for regeneration, wash repeatedly, and centrifugally settle to obtain the crude product of regenerated Cordyceps polysaccharide, and place the crude product of regenerated Cordyceps polysaccharide in a fume hood Fully volatilize the regenerated solvent in the medium, and then dry for 4 hours in an environment with a temperature of 75°C and a vacuum of 0.08KPa to obtain the regenerated Cordyceps polysaccharide;

[0047] 2. A...

Embodiment 3

[0054] A method for measuring polysaccharide sugar components, the specific steps are as follows:

[0055] 1. Ionic liquid pretreatment and polysaccharide regeneration: Weigh 0.2g of condensed polysaccharide that was dried in a vacuum oven at 60°C with a vacuum degree of 0.098kPa for 4 hours, and mix it with 5g of regeneration solvent [Amim]Cl in an oil bath. Dissolve for 4 hours to obtain the coagulated polysaccharide solution; add the coagulated polysaccharide solution to anhydrous ethanol with 5 times the volume of the ionic liquid for regeneration, wash repeatedly, and centrifugally settle to obtain the crude product of the regenerated coagulated polysaccharide, and place the crude product of the regenerated coagulated polysaccharide in ventilation Fully volatilize the regenerated solvent in the cabinet, and then dry for 2 hours in an environment with a temperature of 80°C and a vacuum of 0.05KPa to obtain the regenerated coagulated polysaccharide;

[0056] 2. Acid solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com