Preparation method of visible-light catalyst

A visible light and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of single-phase structure cycle stability and poor ability to degrade methyl orange, and achieve photocatalytic activity optimization , Improve catalytic activity, good interfacial lattice matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

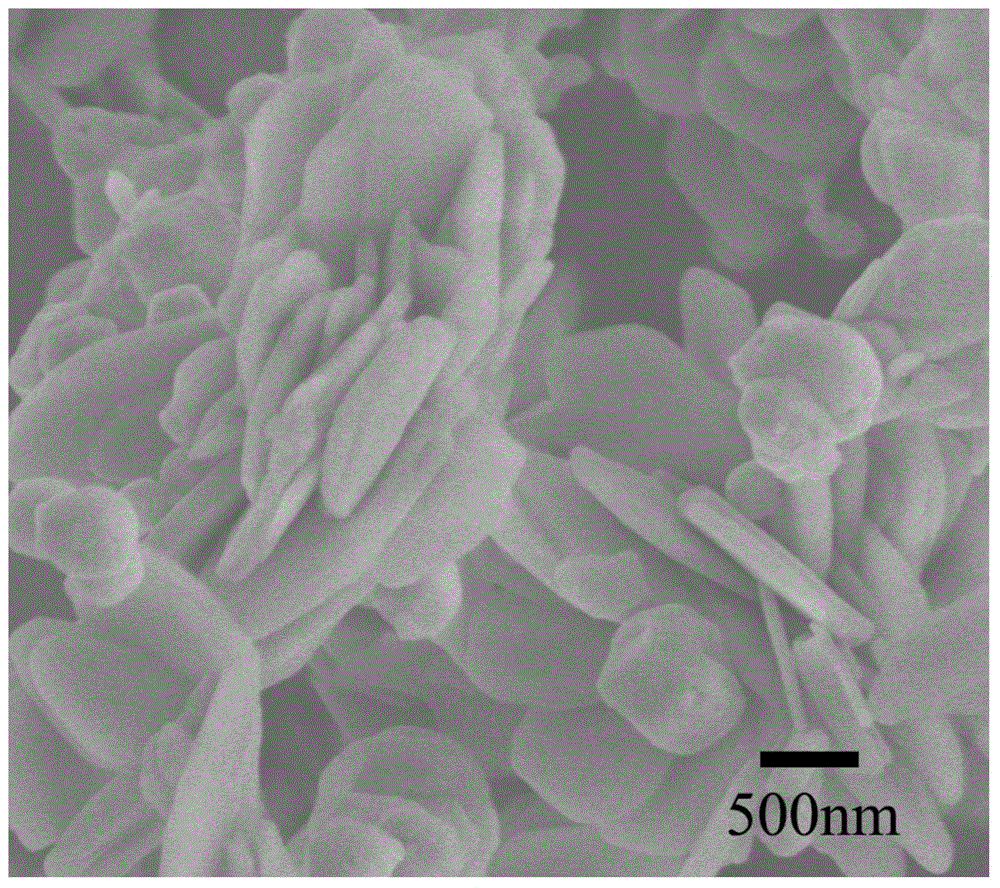

[0023] Embodiment 1: the preparation method of visible light catalyst of the present invention, used material is cobalt phosphate-based composite semiconductor photocatalyst, is made of cobalt phosphate Co 3 (PO 4 ) 2 Nanosheets and silver phosphate Ag 3 PO 4 Nanoparticle composition, silver phosphate, Ag 3 PO 4 Nanoparticles uniformly loaded on cobalt phosphate Co 3 (PO 4 ) 2 On the nanosheet; the cobalt phosphate Co 3 (PO 4 ) 2 The thickness of nanosheets is 100-200nm, silver phosphate Ag 3 PO 4 The particle size of nanoparticles is 200-500nm;

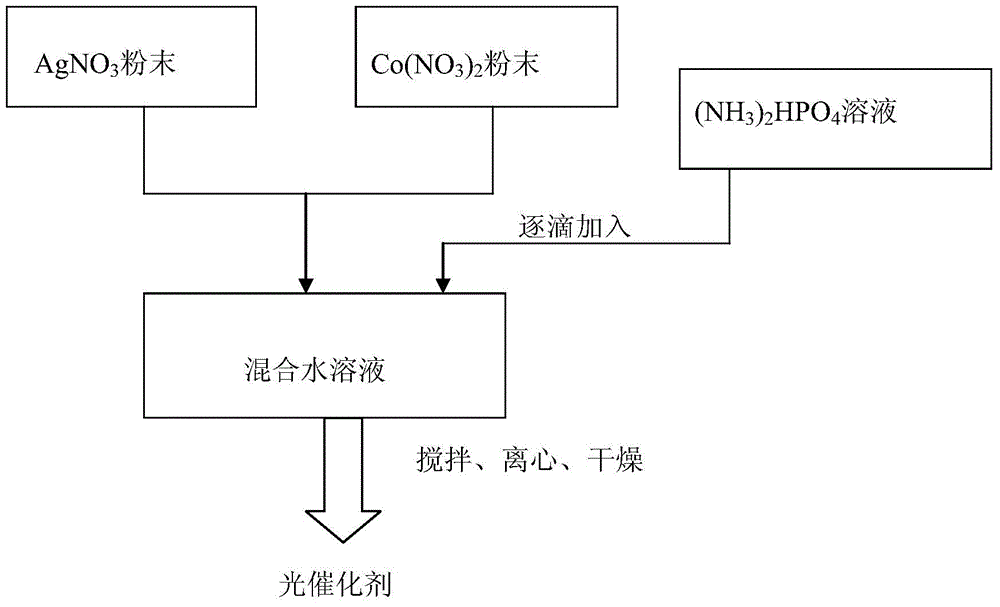

[0024] The preparation method adopts a chemical segregation method, comprising the following steps:

[0025] a) Prepare silver nitrate and cobalt nitrate mixed aqueous solution: weigh 0.1105g silver nitrate powder and 0.1855g cobalt nitrate powder and dissolve them in 100g deionized water to obtain a mixed aqueous solution of the two; the mass percentage concentrations of silver nitrate and cobalt nitrate are 0.1105 % a...

Embodiment 2

[0028] Embodiment 2: the preparation method of visible light catalyst:

[0029] a) Preparation of silver nitrate and cobalt nitrate mixed aqueous solution: weigh 0.051g silver nitrate powder and 0.081g cobalt nitrate powder and dissolve them in 100g deionized water to obtain a mixed aqueous solution, wherein the mass percentage concentration of silver nitrate is 0.05%, and the concentration of cobalt nitrate The mass percentage concentration is 0.08%;

[0030] b) Preparation of diammonium hydrogen phosphate aqueous solution: weigh 0.087g of diammonium hydrogen phosphate powder and dissolve it in 50g of deionized water to obtain a diammonium hydrogen phosphate aqueous solution with a concentration of 0.194%;

[0031] c) Preparation of visible light catalyst: the above-mentioned diammonium hydrogen phosphate solution with a mass percentage concentration of 0.194% is added dropwise to a mixed aqueous solution of silver nitrate and cobalt nitrate, wherein the mass percentage conce...

Embodiment 3

[0032] Embodiment 3: the preparation method of visible light catalyst:

[0033] First, prepare 100g of silver phosphate AgNO with mass percent concentration of 0.17% and 0.29% respectively 3 and cobalt phosphate Co(NO 3 ) 3 aqueous solution, mix the two. It is 0.388% (NH 4 ) 2 HPO 4 100g of aqueous solution, magnetically stirred for 10h, centrifuged to separate the precipitate, washed repeatedly with deionized water and absolute ethanol several times after centrifuged, dried in vacuum to obtain silver phosphate / cobalt phosphate nanocomposite visible light catalyst. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com