Heating composite material and preparation method thereof

A technology of composite materials and thermally conductive insulating materials, which is applied in the field of heating composite material preparation, can solve the problems of difficult to obtain heating composite materials with sandwich structure, complicated experimental devices, etc., and achieves excellent biocompatibility, stable heating, and good interface bonding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of a human body implant composite material with heating function, the steps are as follows:

[0043] The first step, raw material processing:

[0044] Take the Cr20Ni80 nickel-chromium alloy core material with a length of 500mm and a diameter of 8mm and a TA2 titanium tube with a length of 500mm, an outer diameter of 13mm and a wall thickness of 0.5mm. After washing with caustic soda solution for 3 minutes, wash with water, then pickle in a mixed solution of sulfuric acid with a concentration of 18% by mass and NaCl with a concentration of 3% at a temperature of 65°C, and then wash with water for 5 minutes; After being passivated in a nitric acid solution with a temperature of 60°C and a concentration of 8% by mass for 3 minutes, it was washed with water and dried to obtain a core material and a pipe with a silver-white metallic luster on the surface; the aluminum oxide ceramic powder was pretreated at 800°C Heat for 50 minutes.

[0045] The secon...

Embodiment 2

[0057] The preparation method of biomedical heating composite material, the steps are as follows:

[0058] The first step, raw material processing:

[0059] Take the Cr30Ni70 nickel-chromium alloy core material with a length of 550mm and a diameter of 6mm and a TC4 titanium tube with a length of 550mm, an outer diameter of 13mm, and a wall thickness of 0.5mm. After washing with caustic soda solution for 5 minutes, wash with water, then pickle in a mixed solution of sulfuric acid with a concentration of 18% by mass and NaCl with a concentration of 3% at a temperature of 70°C, and then wash with water for 3 minutes; After being passivated in nitric acid solution with a concentration of 8% by mass at 70°C for 5 minutes, washed with water and dried to obtain a core material and a tube with a silver-white metallic luster on the surface; preheat the ITO nano-ceramic powder at 850°C for 50 minute.

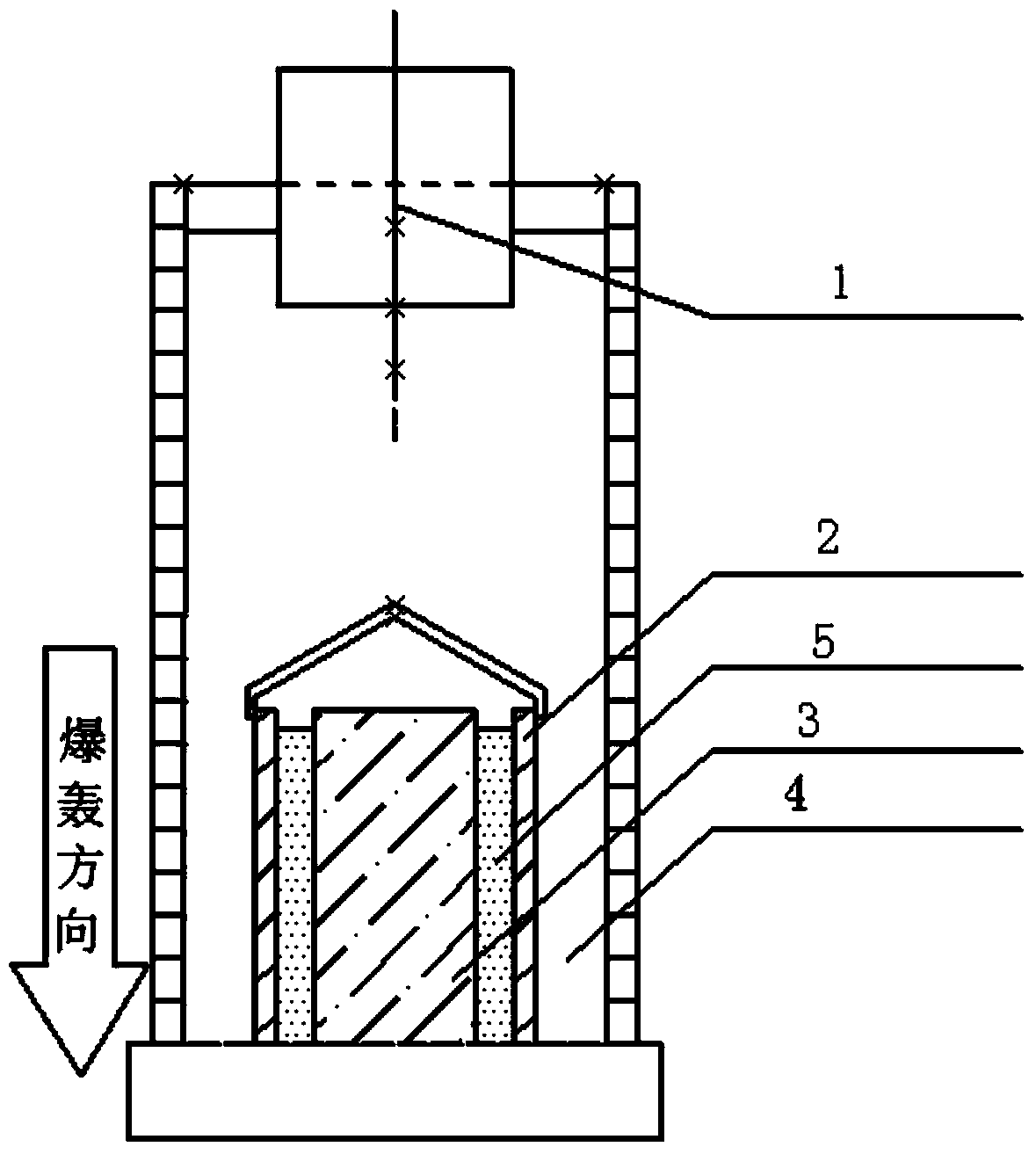

[0060] The second step, explosive compounding:

[0061] See attached figure 1 , p...

Embodiment 3

[0065] The preparation method of biomedical heating composite material, the steps are as follows:

[0066] The first step, raw material surface treatment:

[0067] Take a Cr20Ni35 nickel-chromium-iron alloy core material with a length of 450mm and a diameter of 7mm and a TA2 titanium tube with a length of 450mm, an outer diameter of 15mm and a wall thickness of 1mm, and use industrial caustic soda with a temperature of 450°C and a concentration of 95% by mass. After the solution was washed for 5 minutes, it was washed with water, and then placed in a mixed solution of 18% sulfuric acid and 3% NaCl at a temperature of 65°C and then washed with water for 3 minutes; finally, placed at a temperature of Passivate in 8% nitric acid solution at 60°C for 3 minutes, wash with water and dry to obtain a core material and tube with a silver-white metallic luster on the surface; preheat the silicon carbide ceramic powder at 800°C for 50 minutes .

[0068] The second step, explosive compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com