A preparation method of ultra-thin flexible crystalline silicon battery

A crystalline silicon battery, flexible technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of large efficiency attenuation, few R & D units, low attenuation resistance, etc. The effect of preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

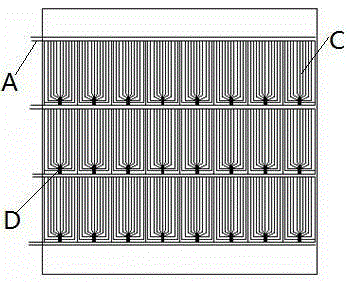

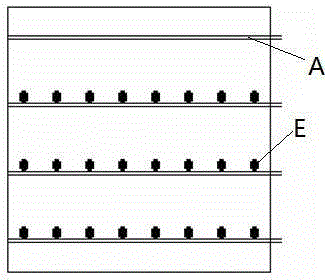

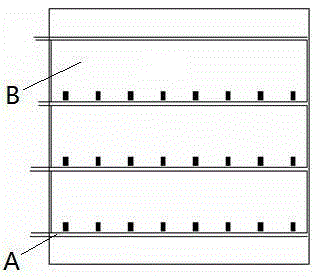

Image

Examples

Embodiment 1

[0036] According to the preparation method of ultra-thin flexible high-efficiency crystalline silicon battery, the present invention uses P-type CFZ single crystal silicon as the substrate, and the specific process flow is as follows:

[0037] The preparation method of the ultra-thin flexible high-efficiency crystalline silicon battery comprises the following steps:

[0038] (1) Make the resistivity 3~5Ω﹒ cm P-type CFZ single crystal silicon wafer cut into 125×125mm with a thickness of 90-120μm 2 or 156×156mm 2 Silicon wafer;

[0039] (2) Clean and texture the cut silicon wafer, and prepare a PN junction with a square resistance of 65-80 Ω / □ on the silicon wafer through a two-step high-temperature diffusion method; the parameters of the two-step high-temperature diffusion method are: The diffusion temperature of the first step is 770-800°C, the diffusion time is 10-20min, the second-step diffusion temperature is 800-850°C, the diffusion time is 15-25min, and the annealing tim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com