Preparation method for ultrathin flexible crystalline silicon battery

A crystalline silicon battery, flexible technology, applied in the direction of circuits, electrical components, semiconductor devices, etc., can solve the problems of low attenuation resistance, few development units, and large efficiency attenuation, so as to reduce production costs, reduce the amount of soldering tape, reduce Effect of component weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

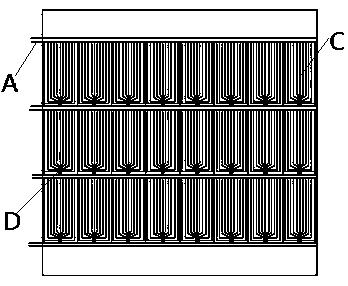

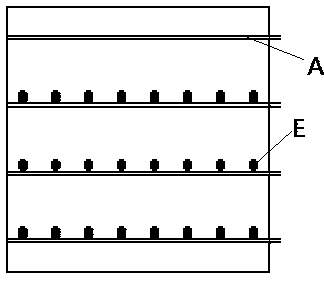

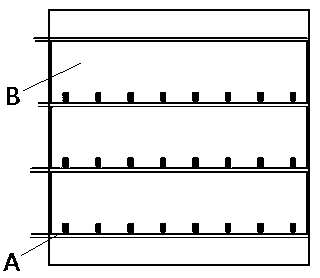

Image

Examples

Embodiment 1

[0036] According to the preparation method of ultra-thin flexible high-efficiency crystalline silicon battery, the present invention uses P-type CFZ single crystal silicon as the substrate, and the specific process flow is as follows:

[0037] The preparation method of the ultra-thin flexible high-efficiency crystalline silicon battery comprises the following steps:

[0038] (1) Make the resistivity 3~5Ω﹒ cm P-type CFZ single crystal silicon wafer cut into 125×125 mm with a thickness of 90-120 μm 2 or 156×156mm2 Silicon wafer;

[0039] (2) Clean and texture the cut silicon wafer, and prepare a PN junction with a square resistance of 65-80 Ω / □ on the silicon wafer through a two-step high-temperature diffusion method; the parameters of the two-step high-temperature diffusion method are: The diffusion temperature of the first step is 770-800°C, the diffusion time is 10-20min, the second-step diffusion temperature is 800-850°C, the diffusion time is 15-25min, and the annealing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com