Preparation method of multilayer graphene structure with controllable twist angle

A multi-layer graphene and twist angle technology, applied in the field of materials, can solve the problem of inability to accurately control the twist angle of graphene layers and layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

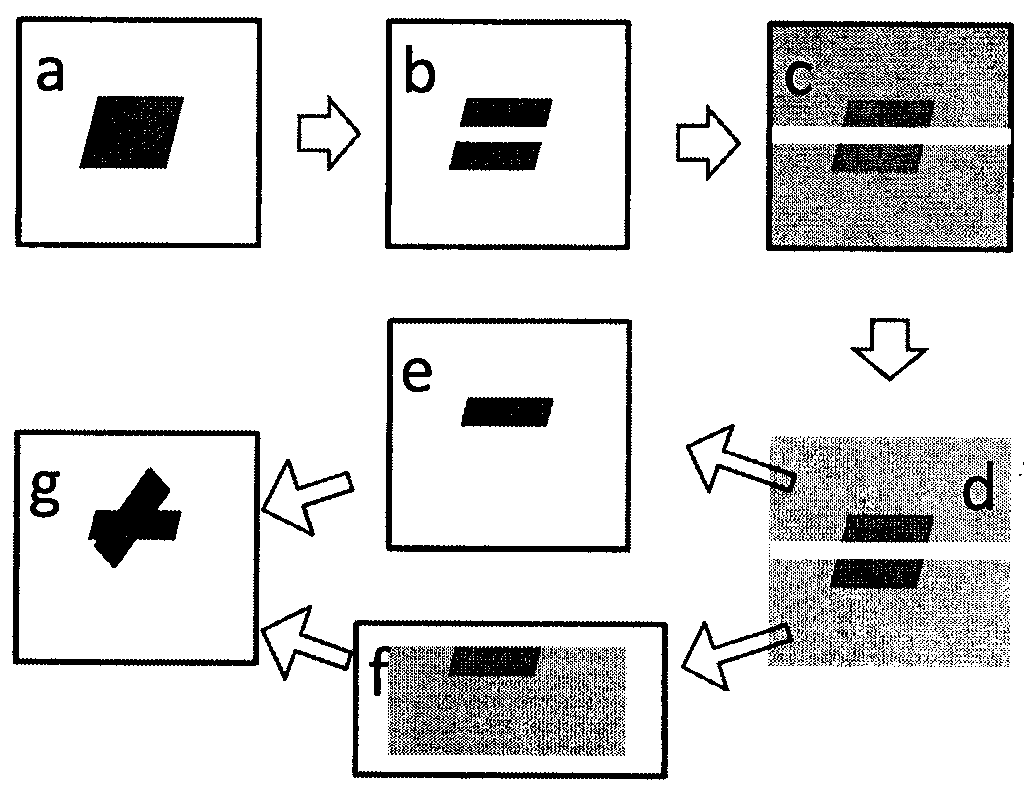

Method used

Image

Examples

Embodiment 1

[0023] In SiO 2 / Si substrate to prepare a double-layer graphene structure with controllable twist angle, comprising the following steps:

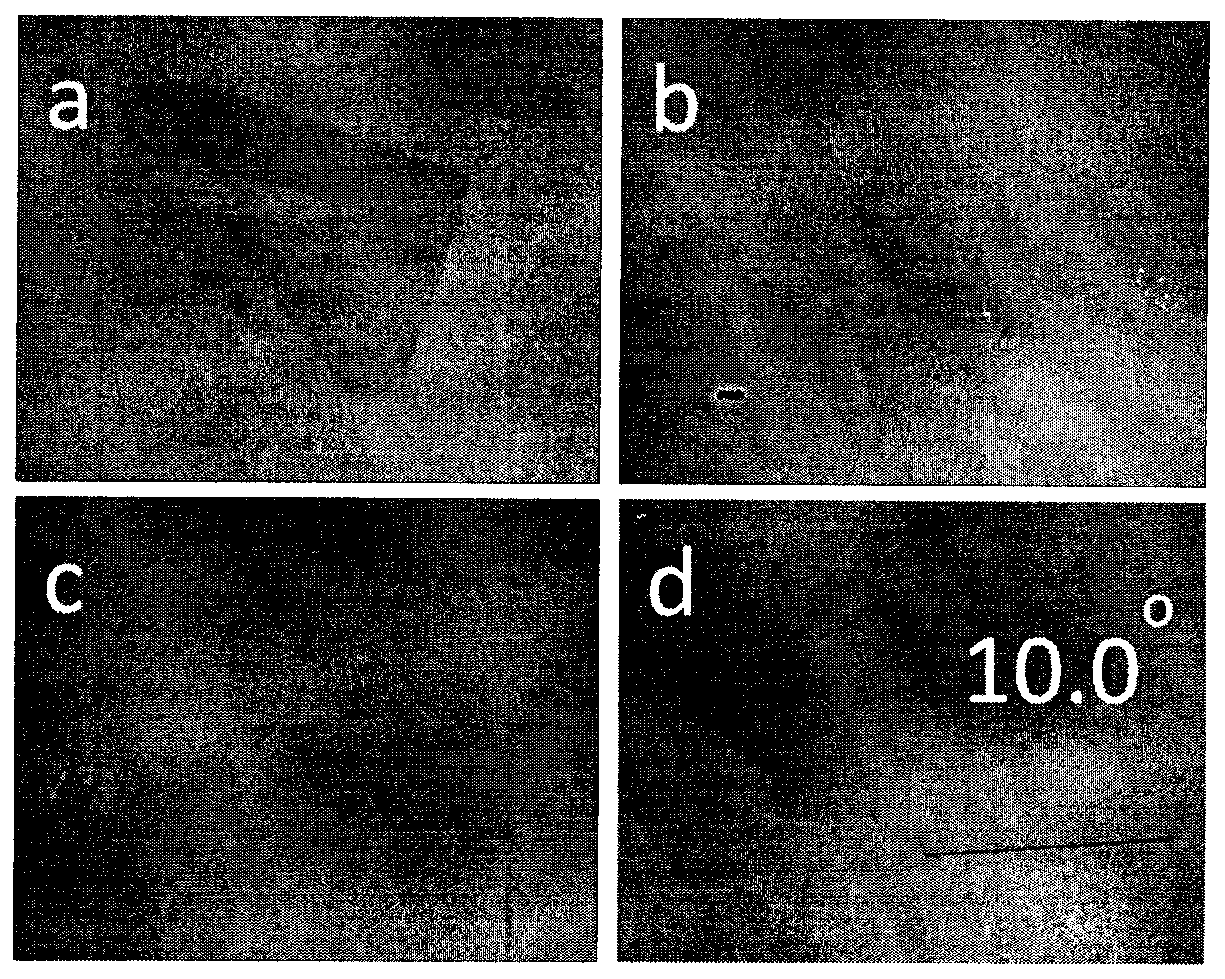

[0024] (1) Using the method of mechanical exfoliation on Si / SiO 2 Prepare single-layer graphene on the substrate, and use a microscope to find the target graphene, substrate SiO 2 The layer thickness is 285nm;

[0025] (2) Under the microscope, use 800nm femtosecond laser to cut the target graphene into two parts, ensure that the edges of the cut graphene are parallel to each other, the objective lens is 100X, the femtosecond laser power is 50mW, and the scanning speed is 5μm / s;

[0026] (3) Spin-coat a layer of PMMA film on the sample, the target graphene is attached on the PMMA layer, the concentration of PMMA / chloroform solution is 0.075mg / ml, the spin-coating speed is 3000rpm, and the time is 30s;

[0027] (4) Use 800nm femtosecond laser under the microscope to cut the PMMA / photoresist layer into two parts in the direction of cu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com