Method for comprehensively using aluminum-containing resource

A resource and alumina technology, applied in the field of comprehensive utilization of resources, can solve the problems that the production cost of alumina is greatly affected, and it is not suitable for processing low-grade bauxite aluminum resources, so as to achieve the effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

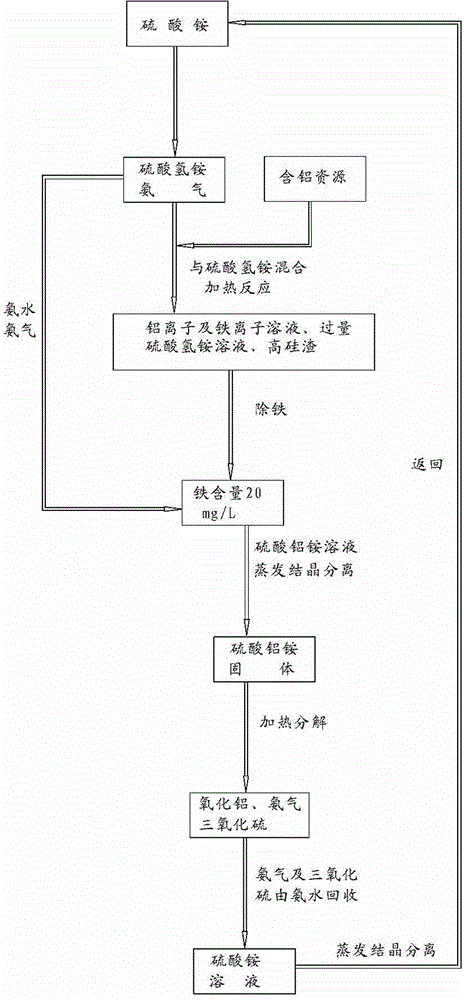

Method used

Image

Examples

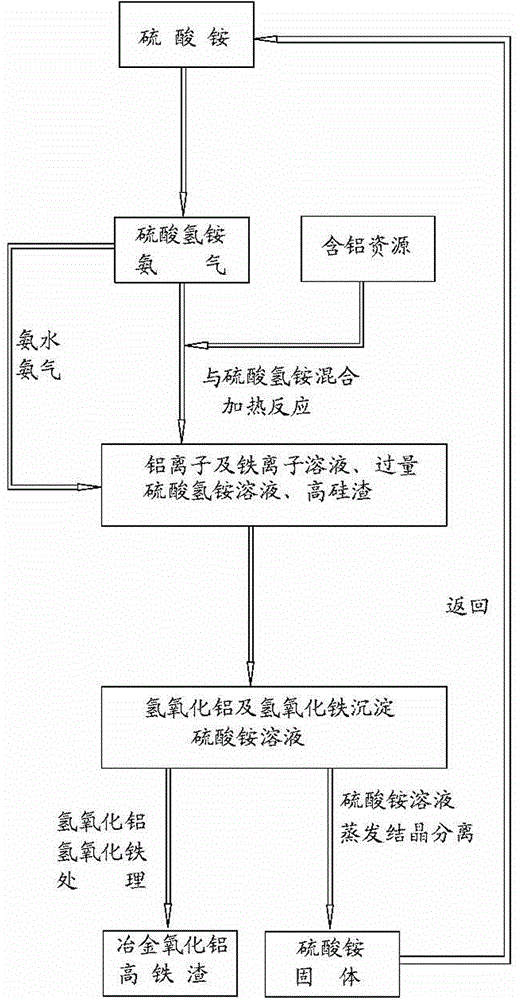

Embodiment 1

[0040] Ammonium sulfate is heated to 300°C for decomposition to produce ammonium bisulfate and ammonia gas, and the ammonia gas is absorbed by water to produce ammonia water. Grind 1000kg of gibbsite-type bauxite and mix it with the above-mentioned ammonium bisulfate, add water, heat to 90°C for reaction, the reaction time is 60min, ammonium bisulfate and alumina in gibbsite-type bauxite And the molar ratio of iron oxide is 7. After the reaction is cooled down, solid-liquid separation and washing are carried out to obtain a solution of aluminum ions and iron ions, excess ammonium bisulfate solution and high-silicon slag, so as to realize the separation of aluminum, iron and silicon; add the ammonia water prepared by the above ammonia gas recovery to the obtained solution to obtain Aluminum hydroxide and ferric hydroxide are precipitated and ammonium sulfate solution, followed by solid-liquid separation and washing; ammonium sulfate solution is evaporated and crystallized, and ...

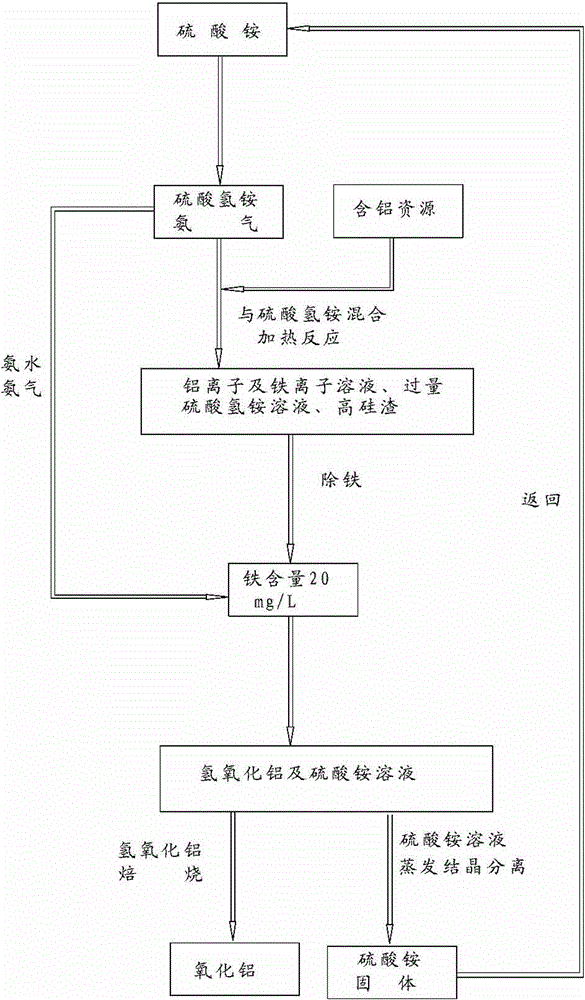

Embodiment 2

[0042] Ammonium sulfate is heated to 200°C for decomposition to produce ammonium bisulfate and ammonia gas, and the ammonia gas is absorbed by water to make ammonia water. Grind 1000kg boehmite-type bauxite and mix it with the above-mentioned ammonium bisulfate, add water, heat to 145°C for reaction, the reaction time is 90min, ammonium bisulfate and boehmite-type bauxite The molar ratio of alumina and iron oxide was 12. After the reaction is cooled down, solid-liquid separation and washing are carried out to obtain a solution of aluminum ions and iron ions, excess ammonium bisulfate solution and high-silicon slag, so as to realize the separation of aluminum, iron and silicon; add the ammonia water prepared by the above ammonia gas recovery to the obtained solution to obtain Aluminum hydroxide and ferric hydroxide are precipitated and ammonium sulfate solution, followed by solid-liquid separation and washing; ammonium sulfate solution is evaporated and crystallized, and the ob...

Embodiment 3

[0044]Ammonium sulfate is heated to 400°C for decomposition to produce ammonium bisulfate and ammonia gas, and the ammonia gas is absorbed with water to make ammonia water. Grind 1000kg of high-alumina fly ash and mix it with the above-mentioned ammonium bisulfate, add water, heat to 280°C for reaction, the reaction time is 30min, the molar ratio of ammonium bisulfate to alumina and iron oxide in high-alumina fly ash for 18. After the reaction is cooled down, solid-liquid separation and washing are carried out to obtain a solution of aluminum ions and iron ions, excess ammonium bisulfate solution and high-silicon slag, so as to realize the separation of aluminum, iron and silicon; add the ammonia water prepared by the above ammonia gas recovery to the obtained solution to obtain Aluminum hydroxide and ferric hydroxide are precipitated and ammonium sulfate solution, followed by solid-liquid separation and washing; ammonium sulfate solution is evaporated and crystallized, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com