Edible mushroom cultivation material prepared by utilization of waste mushroom residues and preparation method thereof

A cultivation material and edible fungus technology, which is applied in the field of edible fungus cultivation materials and its preparation, can solve the problems of miscellaneous bacteria and pests harming the environment of mushroom factories, affecting economic benefits, wasting natural resources, etc., and achieves strong water holding capacity, good air permeability, The effect of increasing nitrogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

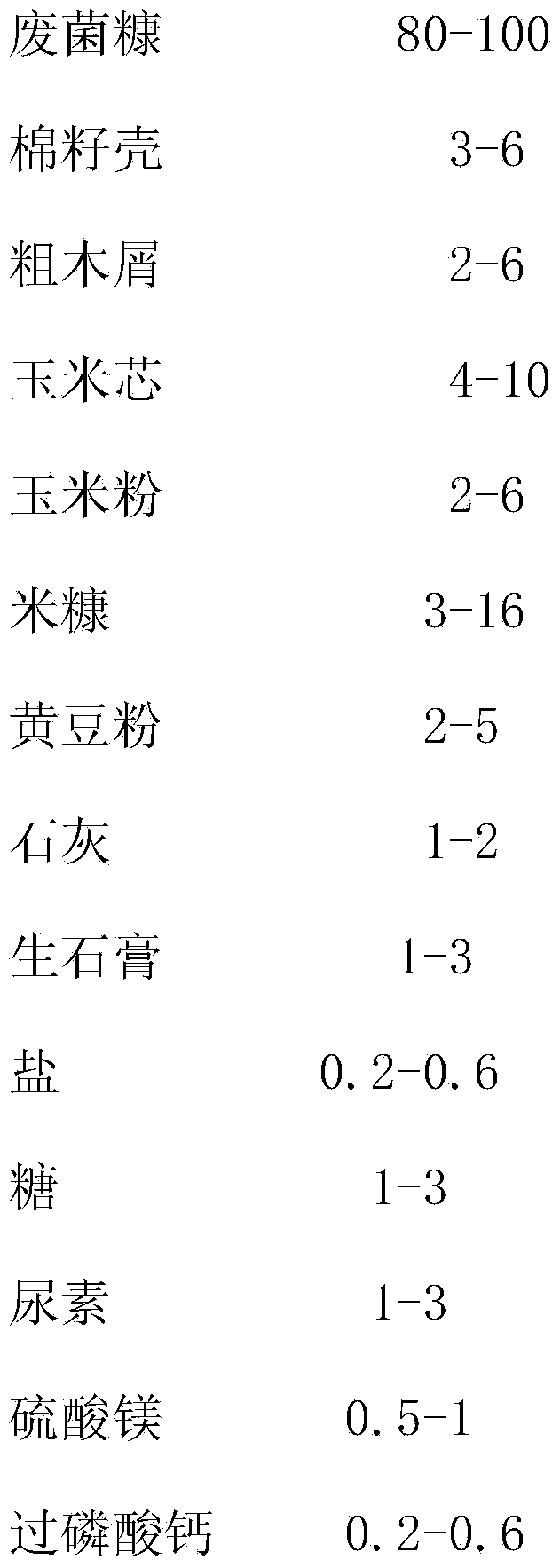

[0015] An edible fungus cultivation material prepared from waste fungus chaff, comprising the following raw materials in parts by weight:

[0016]

[0017]

[0018] The corn cobs are crushed and soaked in 1% lime water for 12 hours before use.

[0019] A kind of preparation method of edible mushroom cultivation material prepared by using waste fungus chaff provided by the invention comprises the following steps:

[0020] (1), remove the residual mushroom legs from the waste fungus chaff, crush them, dry them in the air, and mix them with other raw materials in proportion;

[0021] (2), pile up the mixed cultivation material for fermentation, build a pile with a height of 1m, a width of 1.5m, and a width of 1.5m, sprinkle water for fermentation, control the water content to 55-70%, adjust the pH to 8, turn the pile once every 12 hours, turn the pile for 3 times, the fermentation is complete.

[0022] (3) Pack the fermented cultivation material into bags (size 19×37cm), ...

Embodiment 2

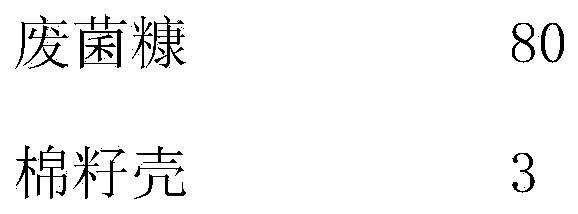

[0025] An edible fungus cultivation material prepared from waste fungus chaff, comprising the following raw materials in parts by weight:

[0026]

[0027] The corncobs are crushed and soaked in 1% lime water for 15 hours before use.

[0028] A kind of preparation method of edible mushroom cultivation material prepared by using waste fungus chaff provided by the invention comprises the following steps:

[0029] (1), remove the residual mushroom legs from the waste fungus chaff, crush them, dry them in the air, and mix them with other raw materials in proportion;

[0030] (2), pile up the mixed cultivation material for fermentation, build a pile with a height of 1m, a width of 1.5m, and a width of 1.5m, sprinkle water for fermentation, control the water content to 55-70%, adjust the pH to 8, turn the pile once every 12 hours, turn the pile for 3 times, the fermentation is complete.

[0031] (3), pack the fermented cultivation material into bags (specification 19×37cm), ste...

Embodiment 3

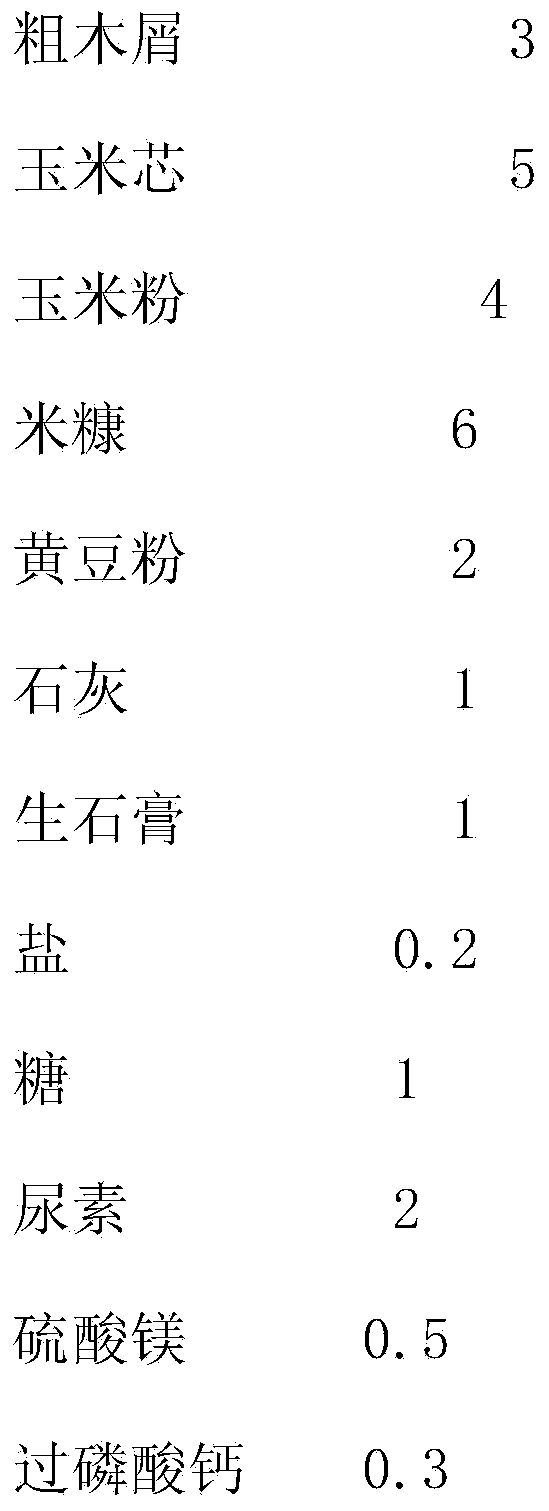

[0034] An edible fungus cultivation material prepared from waste fungus chaff, comprising the following raw materials in parts by weight:

[0035]

[0036]

[0037] The corn cobs are crushed and soaked in 1% lime water for 13 hours before use.

[0038] A kind of preparation method of edible mushroom cultivation material prepared by using waste fungus chaff provided by the invention comprises the following steps:

[0039] (1), remove the residual mushroom legs from the waste fungus chaff, crush them, dry them in the air, and mix them with other raw materials in proportion;

[0040] (2) Pile up the mixed cultivation material for fermentation, build a pile with a height of 1m, a width of 1.5m, and a width of 1.5m, sprinkle water for fermentation, control the water content to 55-70%, adjust the pH to 8.5, turn the pile once every 12 hours, turn over Stack 3 times, the fermentation is complete.

[0041] (3) Pack the fermented cultivation material into bags (size 17×33 cm), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com