Non-vacuum method for producing light absorbing material applied in solar battery

A battery and formula technology, applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of increased surface roughness, long time selenization, adverse effects of battery efficiency, etc., and achieve the effect of low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] According to an exemplary embodiment of the present invention, preferably control about 3mA / cm 2 to about 10mA / cm 2 current density to deposit the selenium layer. The formulation deposition bath will be heated to a preferred temperature range of 60°C to 120°C. In all cases, the deposition bath temperature should be kept constant during the deposition process.

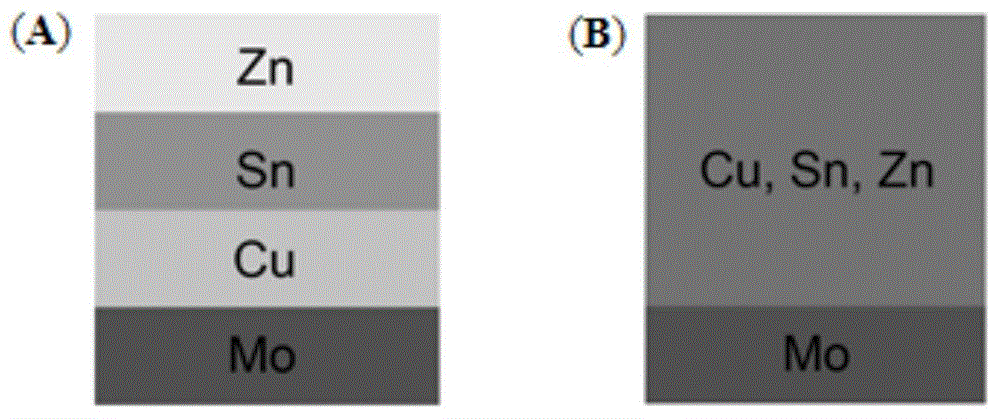

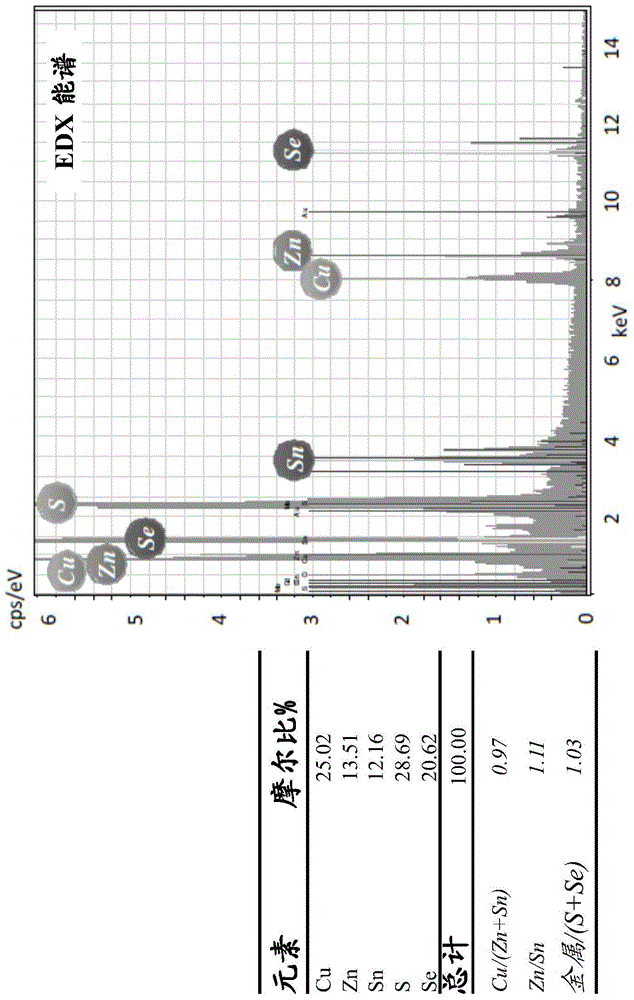

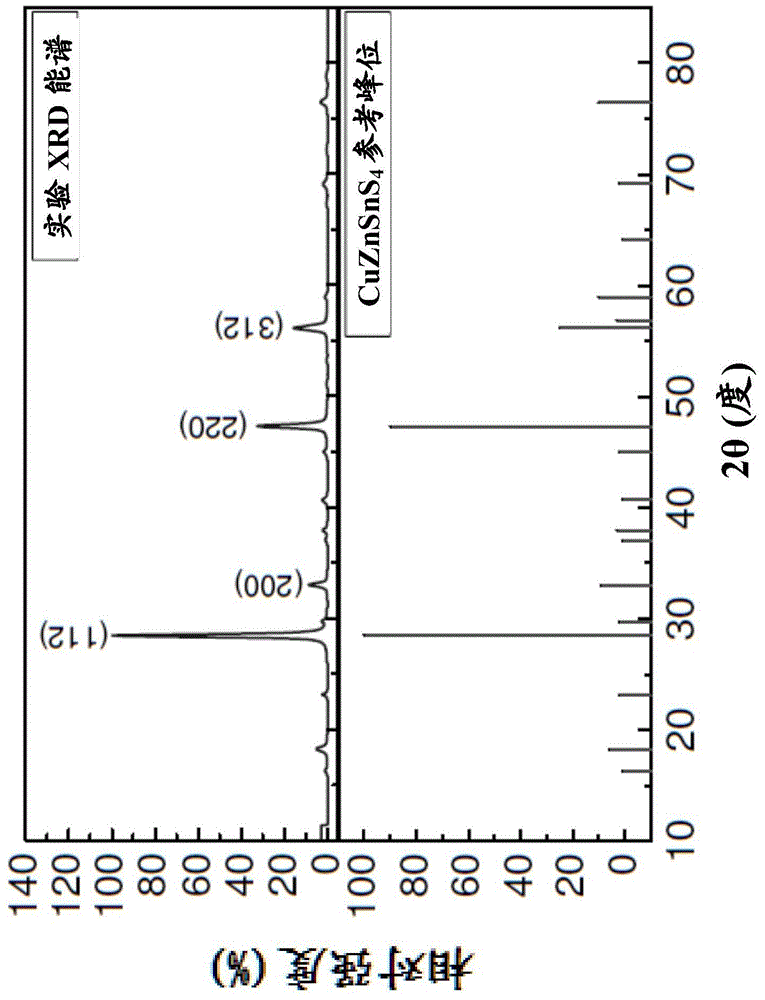

[0038] By using the plating-annealing approach, EDX spectroscopy ( figure 2 ) shows that a CZTS film with an atomic ratio of 2:1:1:4 can be deposited on a conductive substrate, which is the same as the simplest formula of CZTS, that is, Cu 2 ZnSn(S y Se 1-y ) 4 The element ratios are the same. In terms of crystal structure and chemical composition, the obtained CZTS film after annealing shows the same diffraction pattern in the XRD spectrum as the CZTS absorbing layer disclosed in the crystallography database ( image 3 ). These results confirm the feasibility of converting the CZTS precursor stacked la...

Embodiment 1

[0040] Example 1 - Formation of Cu-Zn-Sn alloy by a single deposition bath formulation

[0041] In this example, a Cu-Zn-Sn alloy was prepared by a single deposition bath containing the components of the electroplating recipe. Table 1 provides an exemplary electroplating formulation composition.

[0042] Table 1:

[0043]

[0044]

[0045] In addition to ionic compounds of copper, zinc, and tin, the electroplating composition also contains citrate salts to stabilize the plating bath, and additives to reduce surface roughness, such as surfactants and aldehyde-based compounds. Table 1 lists optimum ranges and examples of each component in the electroplating composition.

[0046] Citrates in the deposition bath formulations in Table 1 can be based on dicarboxylates (e.g. oxalate, malonate, succinate), tricarboxylates (e.g. isocitrate, propane-1,2 ,3-tricarboxylate, benzene-1,3,5-tricarboxylate) and polycarboxylate polymer salt substitution. The substitutes exhibit simil...

Embodiment 2-C

[0048] Sequential sulfurization and selenization of embodiment 2-Cu-Zn-Sn alloy layer

[0049] The annealing step is a necessary process to transform the Cu-Zn-Sn alloy into a CZTS light-absorbing layer. Table 2 illustrates the annealing conditions used for sulfurization and selenization.

[0050] Table 2:

[0051]

[0052]

[0053] Figure 4 The flow chart from the formation of Cu-Zn-Sn alloy to annealing is shown: 401: Formation of Cu-Zn-Sn alloy layer by co-plating on molybdenum (Mo) substrate by single deposition bath formulation; 402: Formation of Cu-Zn-Sn alloy layer by using An inert carrier gas flowing above forms a sulfur-rich atmosphere; 403: Cu-Zn-Sn-S alloy is formed after the first anneal; 404: a selenium-rich atmosphere is formed by using an inert carrier gas flowing over selenium; 405: in A Cu-Zn-Sn-S-Se alloy is formed after the secondary annealing. Figure 5 A schematic is shown outlining the sequential sulfurization and selenization on Cu-Zn-Sn allo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com