Super-junction device and manufacturing method thereof

A super junction and device technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the inability to realize the alternate arrangement structure of P-type semiconductor thin layers and N-type semiconductor thin layers, increase the etching process and silicon Filling process difficulty, increased specific on-resistance, etc., to achieve the effect of low specific on-resistance, reduced process cost, and increased breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

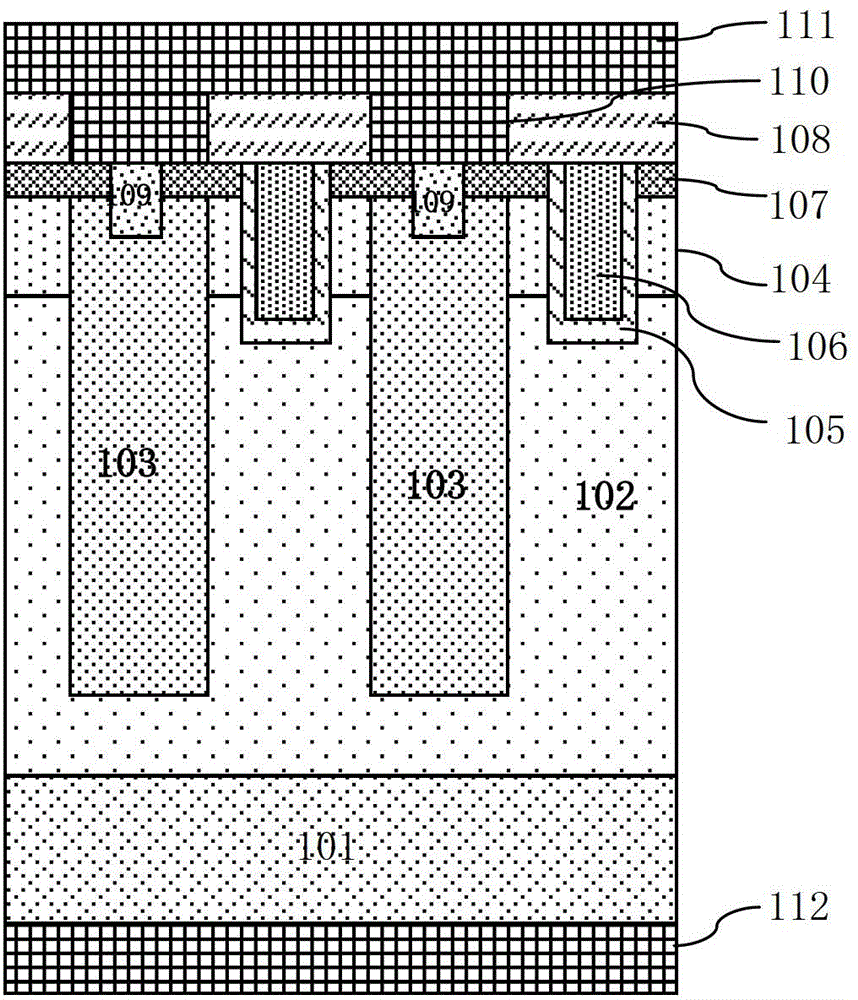

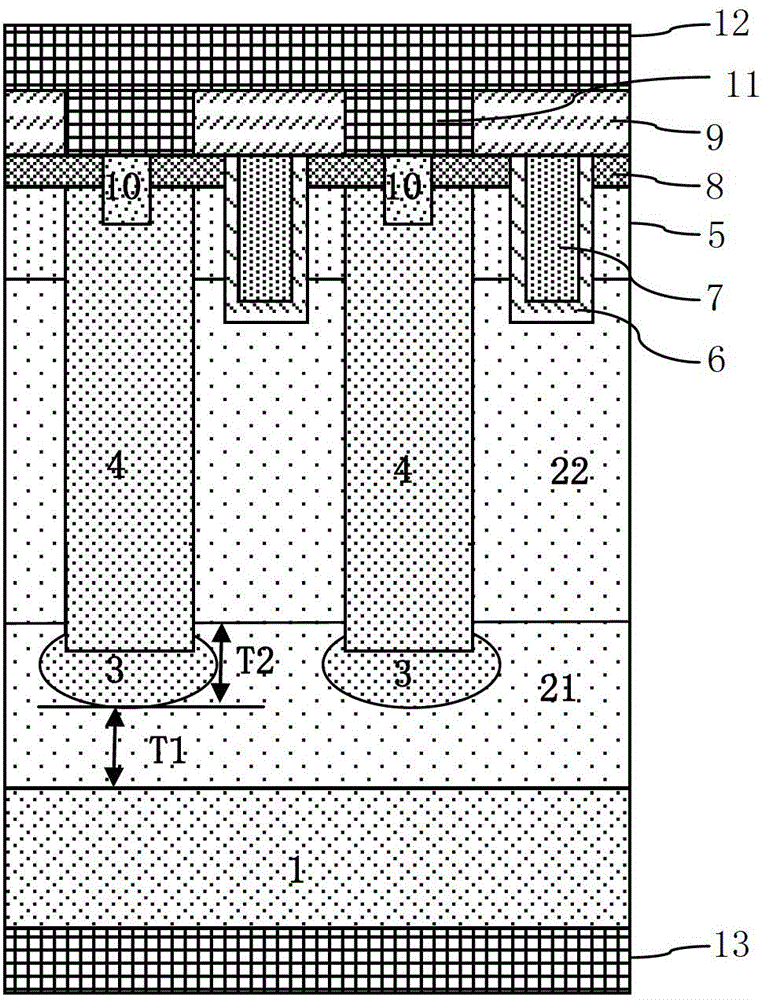

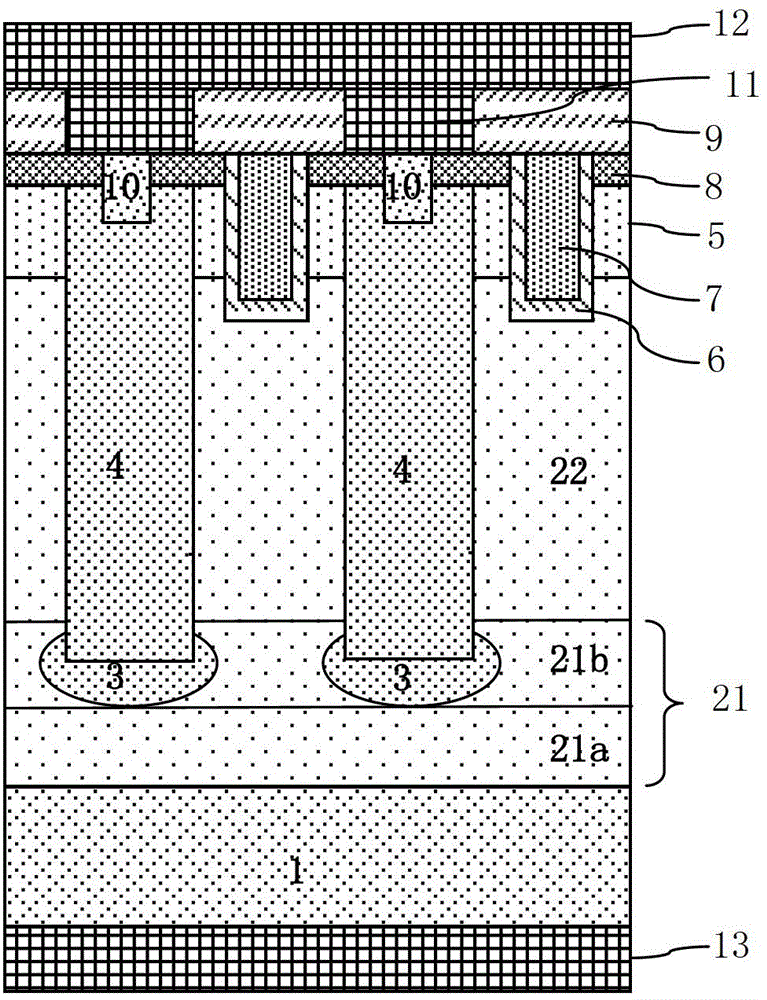

[0035] figure 2 It is a schematic diagram of a super-junction device according to an embodiment of the present invention; a super-junction device according to an embodiment of the present invention is a super-junction NMOSFET device with a breakdown voltage of 600V, and a super-junction device according to an embodiment of the present invention includes:

[0036] On the N+ substrate 1, the substrate 1 is a silicon substrate. The resistivity of the substrate 1 is 0.001 ohm·cm to 0.003 ohm·cm.

[0037] An N-type epitaxial layer is formed on the substrate 1 . The N-type epitaxial layer is composed of a first N-type epitaxial layer 21 and a second N-type epitaxial layer 22 sequentially formed on the substrate 1 . The first N-type epitaxial layer 21 is uniformly doped, such as a doping concentration of 1 ohm·cm; the doping concentration of the second N-type epitaxial layer 22 is also 1 ohm·cm, and the first N-type epitaxial The thickness of the layer 21 is 15 microns, and the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com