A method for modifying the absorption layer of copper-zinc-tin-selenium thin-film solar cells

A technology of copper-zinc-tin-selenium thin film and solar cells, which is applied in the direction of circuits, electrical components, climate sustainability, etc., can solve the problems of high equipment requirements, long time consumption, and restrictions on wide application, and achieve simple modification process and easy operation The effect of convenience and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

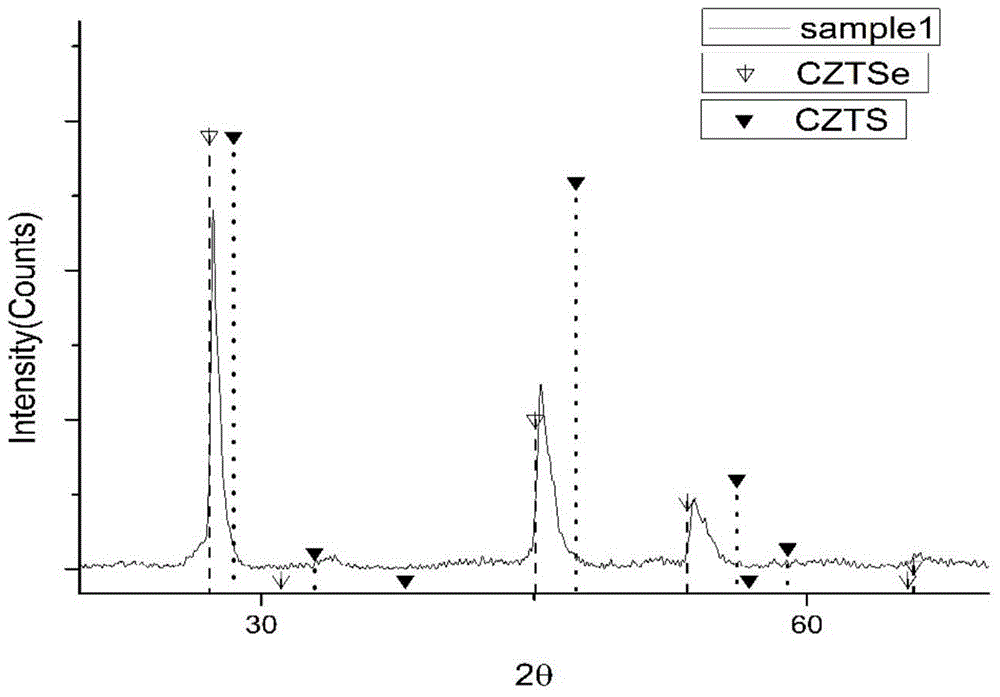

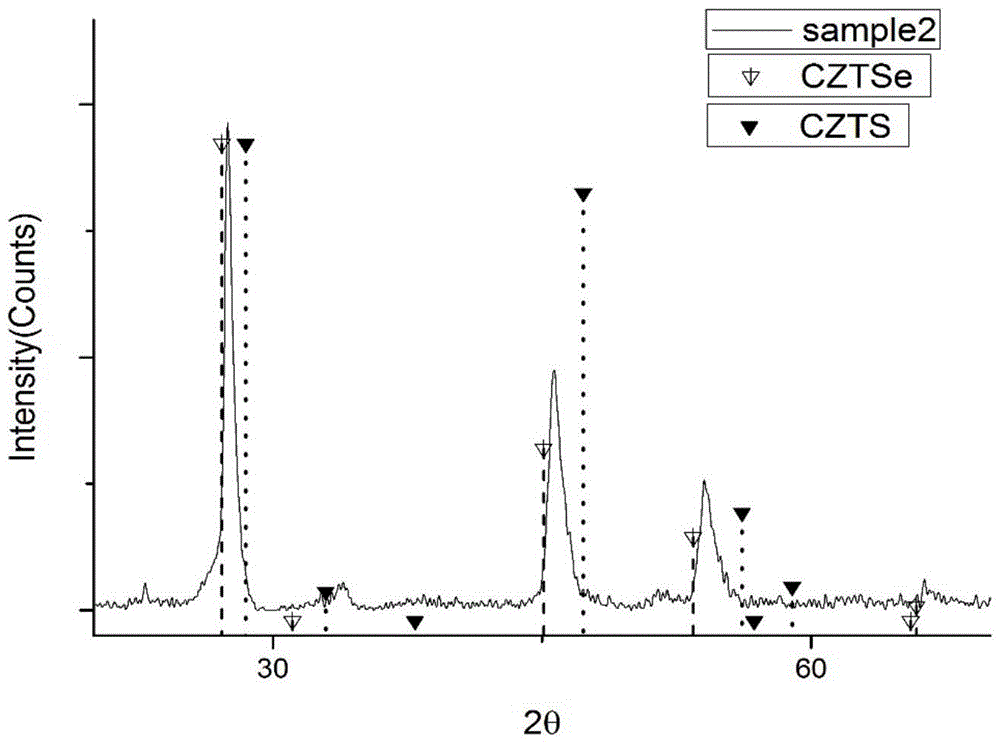

Image

Examples

Embodiment 1

[0021] A method for modifying the absorption layer of a copper-zinc-tin-selenium thin-film solar cell, comprising the following steps:

[0022] Step 1: Prepare a copper-zinc-tin-selenium absorbing layer on the molybdenum-coated soda-lime glass: first, place the molybdenum-coated soda-lime glass in a vacuum of 10 -5 In a vacuum environment of Pa, copper, zinc and tin with a purity of 99.999wt% are used as target materials, and argon gas with a purity of 99.999% (volume percentage) is input as a sputtering medium, at room temperature, power 50W, sputtering pressure (working Under the condition of 0.8Pa, direct current sputtering method was used to sputter copper for 30min, zinc for 17min, and tin for 15min respectively; Under pre-annealing for 4 hours; finally add 6mg of selenium powder, selenium annealing at 560°C for 2 hours, take out after annealing and rapidly cool down.

[0023] Step 2: Preparing the precursor solution: Add 0.005mol zinc chloride and 0.1mol thioacetamide t...

Embodiment 2

[0028] A method for modifying the absorption layer of a copper-zinc-tin-selenium thin-film solar cell, comprising the following steps:

[0029] Step 1: Prepare copper-zinc-tin-selenium absorption layer on molybdenum-plated soda-lime glass: first, add 0.0025mol copper chloride, 0.00125mol zinc sulfate, and 0.00125mmol stannous sulfate to 0.05L deionized water, stir to make it fully Dissolve to obtain mixed solution A, add 0.005mol selenium powder to 0.03L ethylenediamine, stir evenly to obtain mixed solution B, then mix mixed solution A and mixed solution B, stir evenly, and react at 200°C for 24h ; The solution after the reaction was centrifuged for 5min, poured out the supernatant, added 0.01L deionized water for ultrasonication, repeated the above steps for 6 times, and the rotating speed of each centrifugal was 6000 rpm to obtain the copper-zinc-tin dispersed in deionized water Selenium ink; Finally, spin-coat the above-mentioned copper-zinc-tin-selenium ink on molybdenum-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com