Membrane-free direct alcohol fuel cell in acid solution and preparation method thereof

An acidic solution and fuel cell technology, applied in fuel cells, battery electrodes, circuits, etc., can solve the problems that cannot be applied to direct alcohol fuel cells without membranes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Mix 100 mg multi-walled carbon nanotubes (MWCNTs), 50 mL 10 mmol L -1 Palladium chloride solution, 12mL 10 mmol L -1 Cobalt chloride solution and 14 mL of 10 mmol L -1 Mix the copper chloride solution, then add 290 mg ethylenediaminetetraacetic acid disodium salt, stir the mixture well for 1 hour, then slowly add 50 mmol L -1 Sodium hydroxide solution until the pH of the mixture reaches 6. Continue to stir the mixture, slowly add 50 mL of sodium borohydride solution (30% by mass) dropwise, and continue stirring the mixture for 1 hour after the addition is complete. The mixture was filtered, and the resulting solid was washed with a large amount of water to neutrality, and then vacuum-dried at room temperature for 24 hours to obtain palladium-cobalt-copper nanocomposites (PdCoCu / MWCNT) supported on multi-walled carbon nanotubes (MWCNTs).

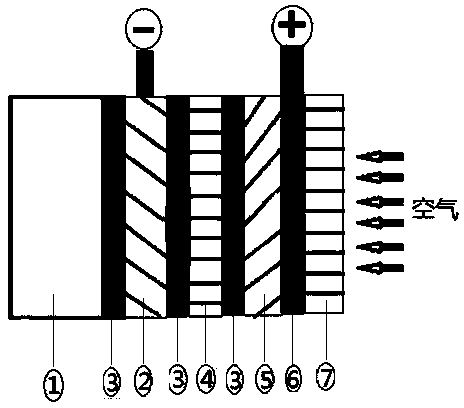

[0028] (2) Prepare the gas diffusion electrode, the preparation steps are as follows:

[0029] Step 1: Preparation of the cata...

Embodiment 2

[0042] (1) Mix 150 mg multi-walled carbon nanotubes (MWCNTs), 70 mL 10 mmol L -1 Palladium chloride solution, 18 mL 10 mmol L -1 Cobalt chloride solution and 22 mL of 10 mmol L -1 Mix the copper chloride solution, then add 450 mg ethylenediaminetetraacetic acid disodium salt, stir the mixture well for 1 hour, then slowly add 50 mmol L -1 Sodium hydroxide solution until the pH of the mixture reaches 6. Continue to stir the mixture, slowly add 80 mL of sodium borohydride solution (30% by mass) dropwise, and continue stirring the mixture for 1 hour after the addition is complete. The mixture was filtered, and the resulting solid was washed with a large amount of water to neutrality, and then vacuum-dried at room temperature for 24 hours to obtain palladium-cobalt-copper nanocomposites (PdCoCu / MWCNT) supported on multi-walled carbon nanotubes (MWCNTs).

[0043] (2) Prepare the gas diffusion electrode, the preparation steps are as follows:

[0044] Step 1: Preparation of the cat...

Embodiment 3

[0057] (1) Mix 200 mg multi-walled carbon nanotubes (MWCNTs), 100 mL 10 mmol L -1 Palladium chloride solution, 24mL 10 mmol L -1 Cobalt chloride solution and 28 mL 10 mmol L -1 Mix the copper chloride solution, then add 600 mg ethylenediaminetetraacetic acid disodium salt, stir the mixture well for 1 hour, then slowly add 50 mmol L -1 Sodium hydroxide solution until the pH of the mixture reaches 6. Continue to stir the mixture, slowly add 100 mL of sodium borohydride solution (30% by mass) dropwise, and continue stirring the mixture for 1 hour after the addition is complete. The mixture was filtered, and the resulting solid was washed with a large amount of water to neutrality, and then vacuum-dried at room temperature for 24 hours to obtain palladium-cobalt-copper nanocomposites (PdCoCu / MWCNT) supported on multi-walled carbon nanotubes (MWCNTs).

[0058] (2) Prepare the gas diffusion electrode, the preparation steps are as follows:

[0059] Step 1: Preparation of the catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com