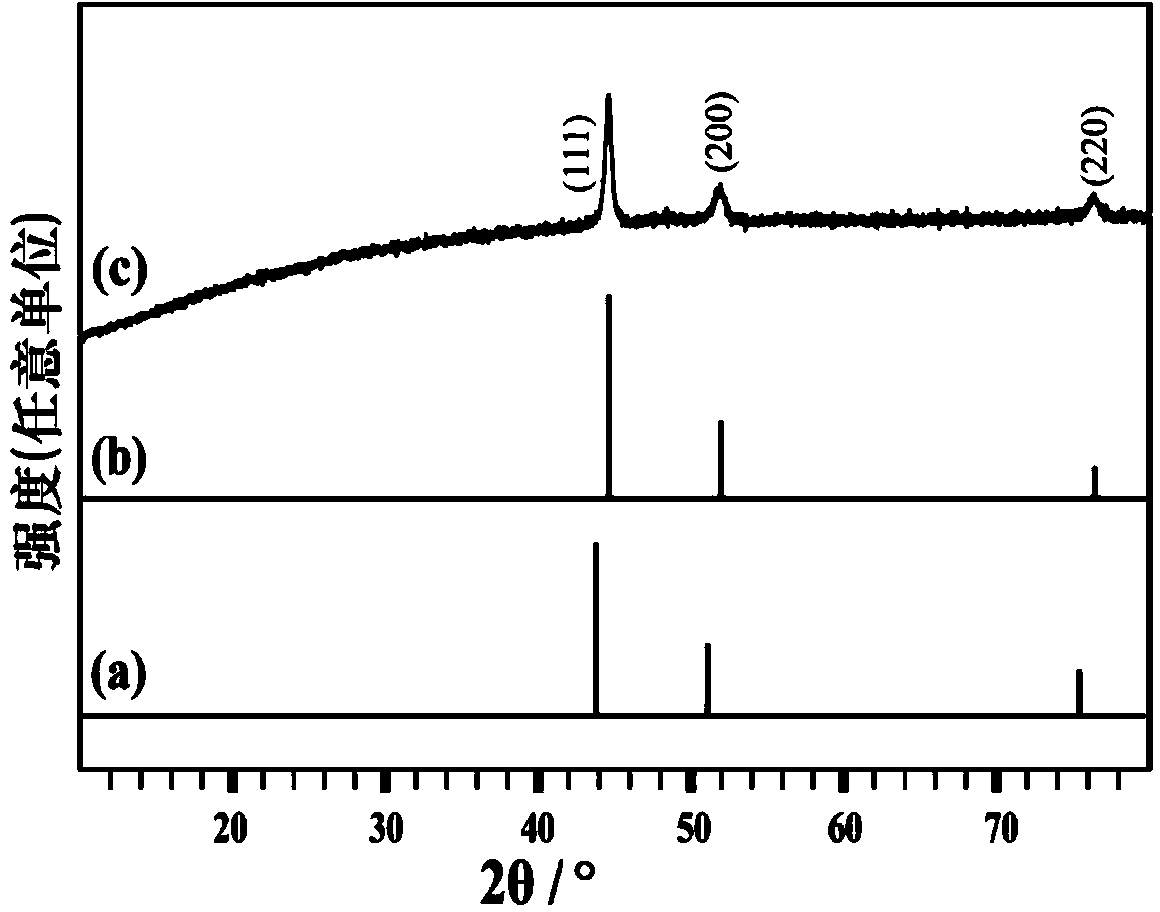

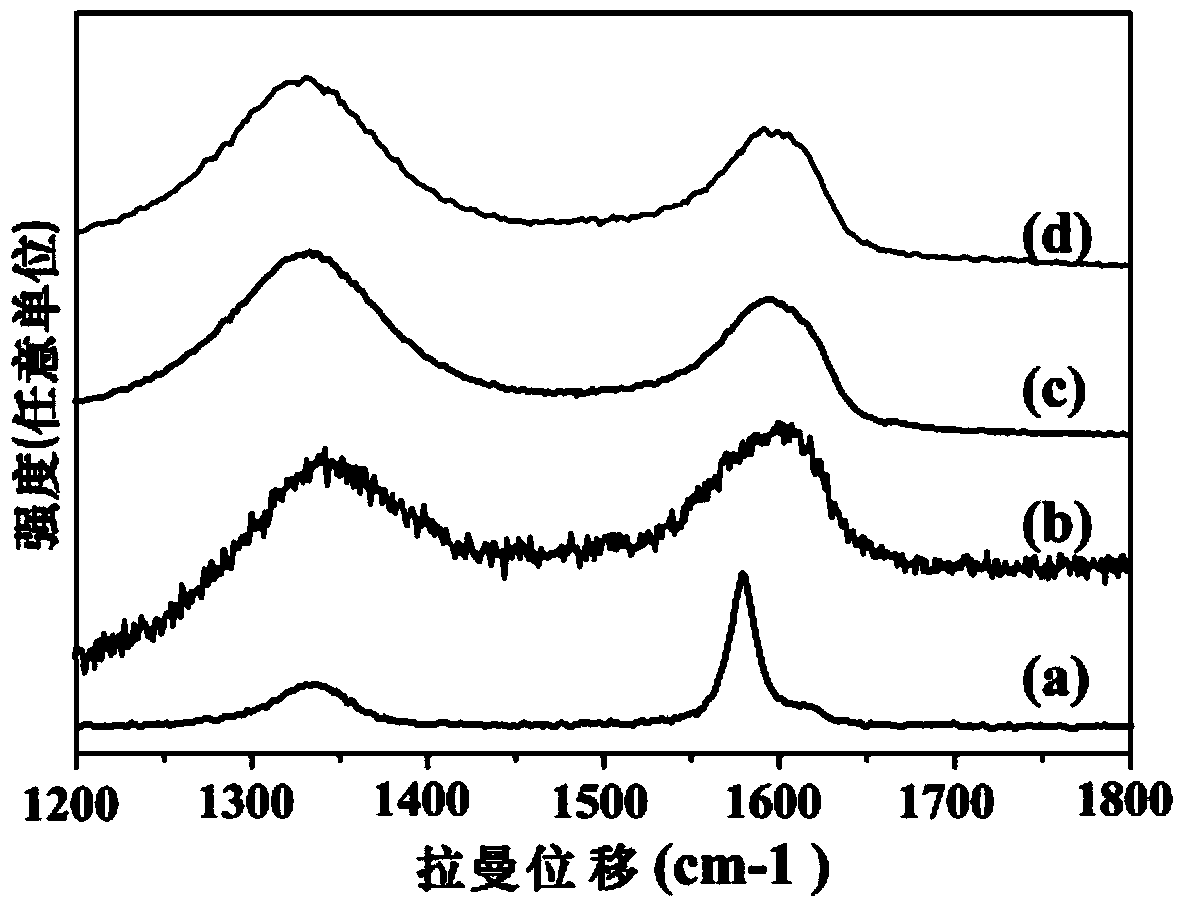

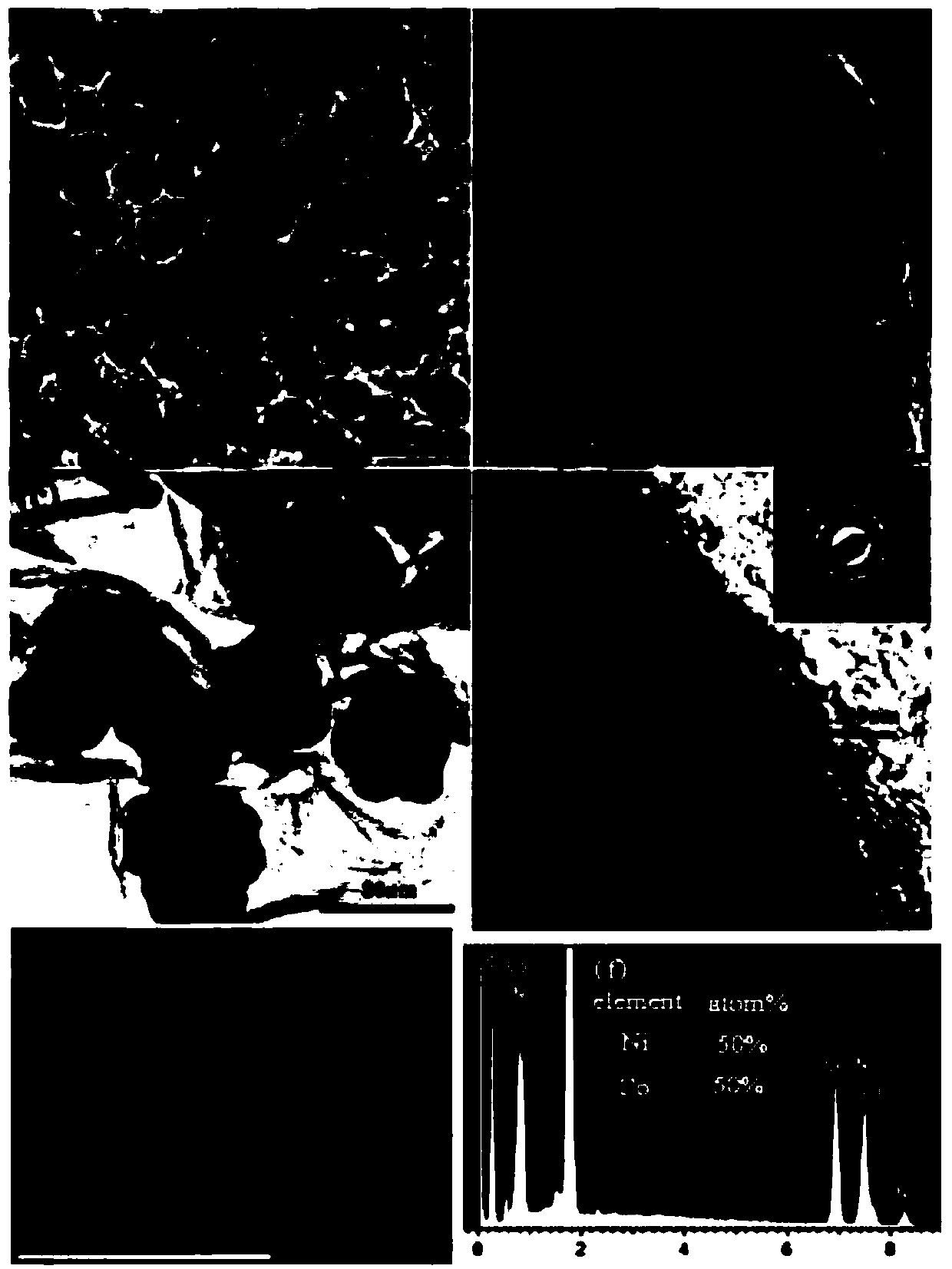

Cubic-phase cobalt-nickel alloy nano-cluster-graphene composite material and manufacturing method and purpose thereof

A technology of cobalt-nickel alloy and composite materials, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of small particle size and easy oxidation, and the method is simple and easy to absorb. The effect of good wave performance and cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of raw graphite oxide and composites

[0036] Preparation of graphite oxide

[0037] Graphite oxide was prepared by the modified Hummers method as a raw material for the preparation of cubic cobalt-nickel alloy-graphene composites.

[0038] Weigh 5 grams of graphite powder (Shanghai Yifan Graphite Co., Ltd., AR), 5 grams of NaNO 3 (Xilong Chemical Factory, Shantou City, Guangdong, AR), and 230 ml concentrated H 2 SO 4 (Beijing Chemical Plant, AR), placed in an ice-water bath, slowly added 30 g of KMnO 4 (Tianjin Kemiou Chemical Reagent Development Company, AR), this process takes about 15 minutes.

[0039] Remove the ice-water bath, put it in a 35°C water bath, and slowly add 460 ml of distilled water. During this process for about 30 minutes, the product gradually turns from black to brown.

[0040] Then put it in a 98°C oil bath for 15 minutes.

[0041] After withdrawing from the oil bath, add 1400 ml warm water, stir, add 100 ml H 2 o 2 (Beijing Che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com