Bismuth sodium titanate base and barium titanate base multilayer composite piezoelectric film and preparation method thereof

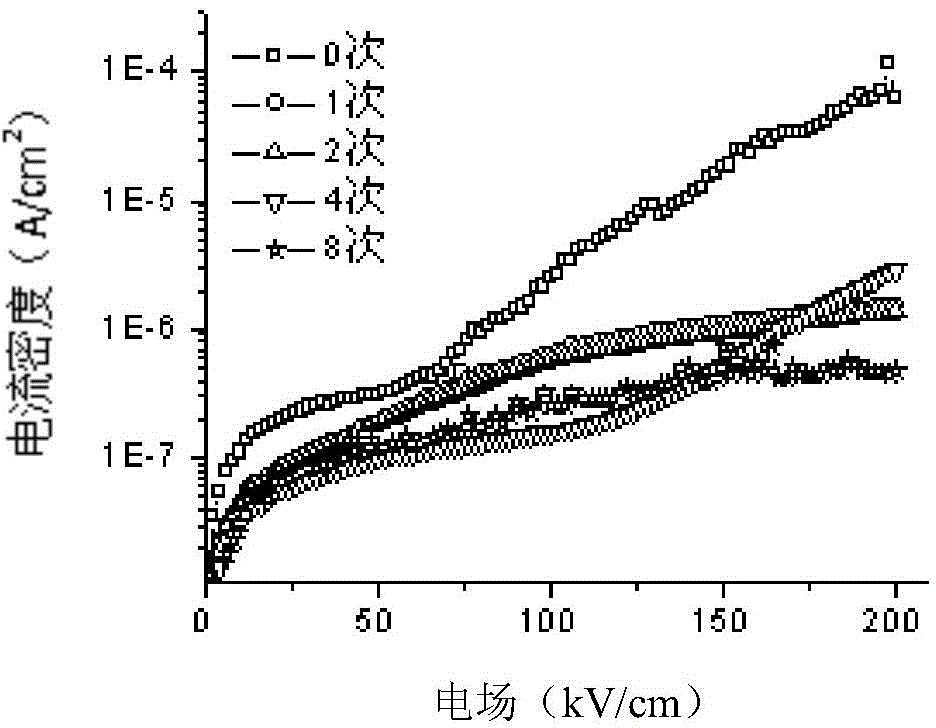

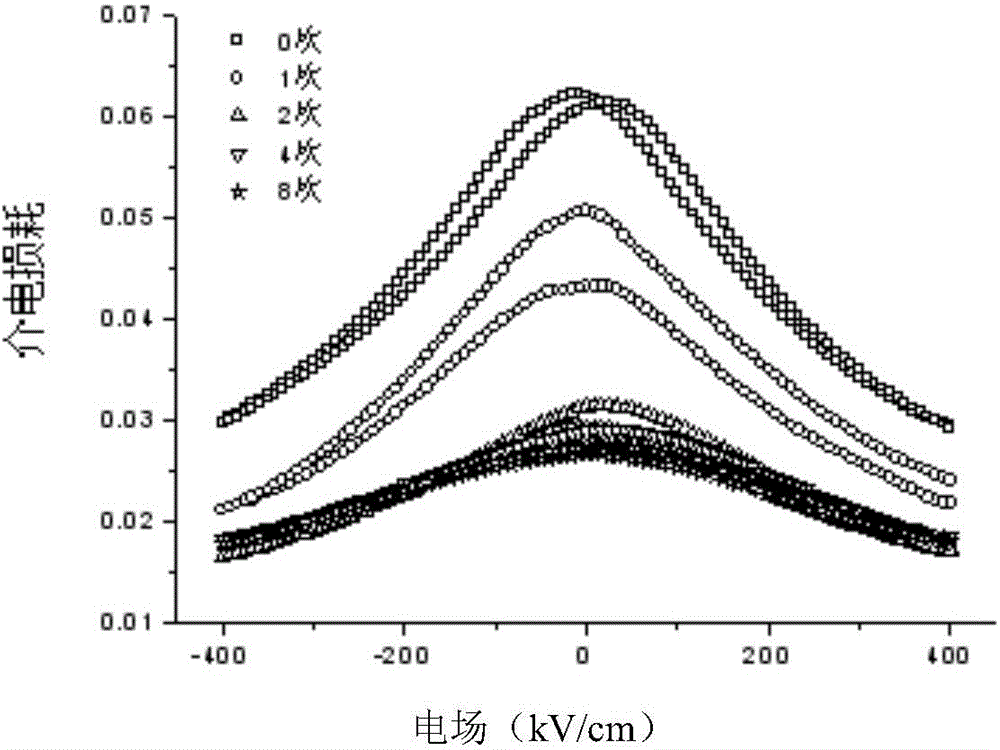

A sodium bismuth titanate-based, composite piezoelectric technology, applied in the manufacture/assembly of piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, circuits, etc., to achieve low loss and superior applications The effect of foreground, low leakage conductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

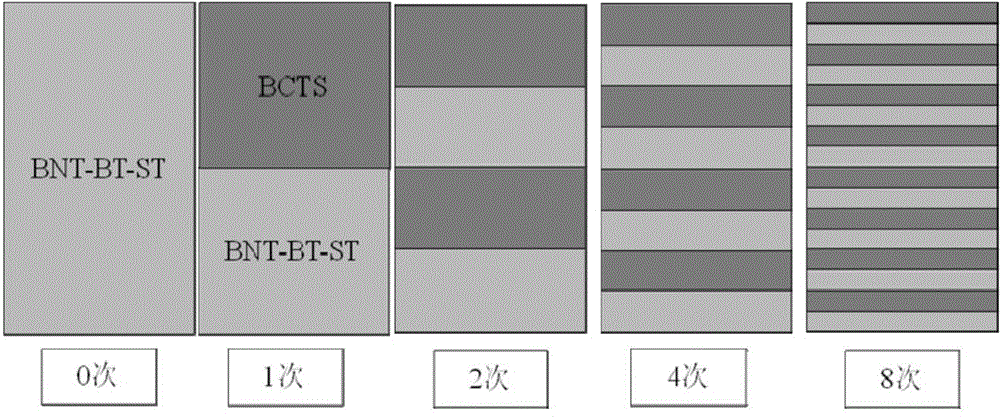

[0037] In this example, a bismuth sodium titanate-based and barium titanate-based multilayer composite piezoelectric film with a heterostructure cycle period of 0 is prepared. The specific experimental steps are as follows:

[0038] (1) According to the general chemical formula 0.755Bi 1 / 2 Na 1 / 2 TiO 3 -0.065BaTiO 3 -0.18SrTiO 3 Middle Bi 1 / 2 Na 1 / 2 TiO 3 Weigh raw materials, dissolve bismuth nitrate and sodium nitrate in glacial acetic acid, stir and heat to boiling for 10 minutes to prepare solution ①, dissolve titanium isopropoxide and complexing agent acetylacetone in ethylene glycol ethyl ether, 50°C Stir for 60 minutes to prepare solution ②, slowly add solution ② to solution ①, and control the solution concentration at 0.2mol / L, and stir at 50°C for 60 minutes to prepare precursor solution A;

[0039] (2) According to the general chemical formula 0.755Bi 1 / 2 Na 1 / 2 TiO 3 -0.065BaTiO 3 -0.18SrTiO 3 Medium BaTiO 3 The stoichiometric ratio of the raw material w...

Embodiment 2

[0048] In this example, bismuth sodium-based and barium titanate-based multilayer composite piezoelectric films with a heterogeneous structure cycle period of 1 were prepared. The specific experimental steps are as follows:

[0049] (1) According to the general chemical formula 0.755Bi 1 / 2 Na 1 / 2 TiO 3 -0.065BaTiO 3 -0.18SrTiO 3 Middle Bi 1 / 2 Na 1 / 2 TiO 3 Weigh raw materials, dissolve bismuth nitrate and sodium nitrate in glacial acetic acid, stir and heat to boiling for 10 minutes to prepare solution ①, dissolve titanium isopropoxide and complexing agent acetylacetone in ethylene glycol ethyl ether, 50°C Stir for 60 minutes to prepare solution ②, slowly add solution ② to solution ①, and control the solution concentration at 0.2mol / L, and stir at 50°C for 60 minutes to prepare precursor solution A;

[0050] (2) According to the general chemical formula BaTiO 3 The stoichiometric ratio of the raw material was weighed barium acetate and stirred and heated to boiling for ...

Embodiment 3

[0063] In this example, a bismuth sodium-based and barium titanate-based multilayer composite piezoelectric film with a heterogeneous structure with a cycle period of 2 is prepared. The specific experimental steps are as follows:

[0064] (1) According to the general chemical formula 0.755Bi1 / 2 Na 1 / 2 TiO 3 -0.065BaTiO 3 -0.18SrTiO 3 Middle Bi 1 / 2 Na 1 / 2 TiO 3 Weigh raw materials, dissolve bismuth nitrate and sodium nitrate in glacial acetic acid, stir and heat to boiling for 10 minutes to prepare solution ①, dissolve titanium isopropoxide and complexing agent acetylacetone in ethylene glycol ether, 70°C Stir for 60 minutes to prepare solution ②, slowly add solution ② to solution ①, and control the solution concentration at 0.2mol / L, and stir at 70°C for 60 minutes to prepare precursor solution A;

[0065] (2) According to the general chemical formula BaTiO 3 The stoichiometric ratio of the raw material was weighed barium acetate and stirred and heated to boiling for 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com