Novel texture paint

A textured paint, a new type of technology, applied in the direction of polyester coatings, coatings, etc., can solve the problems of difficult construction and large amount of textured paint, and achieve the effects of reducing cost and amount, improving workability, and increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

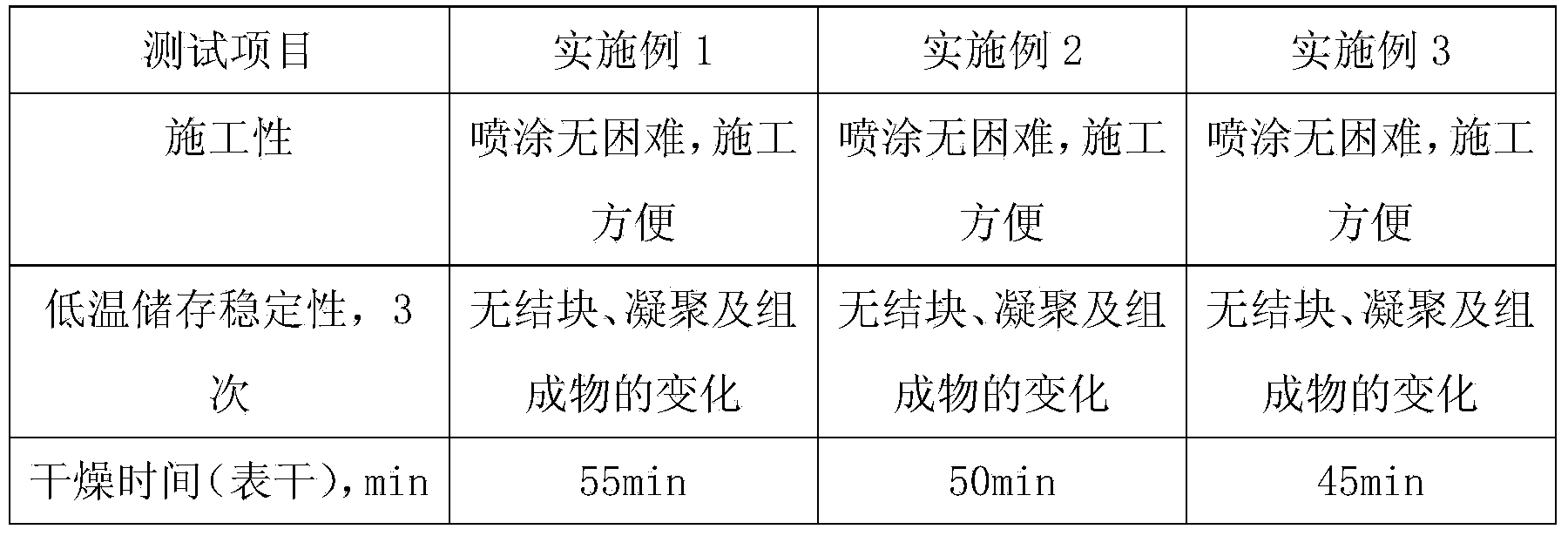

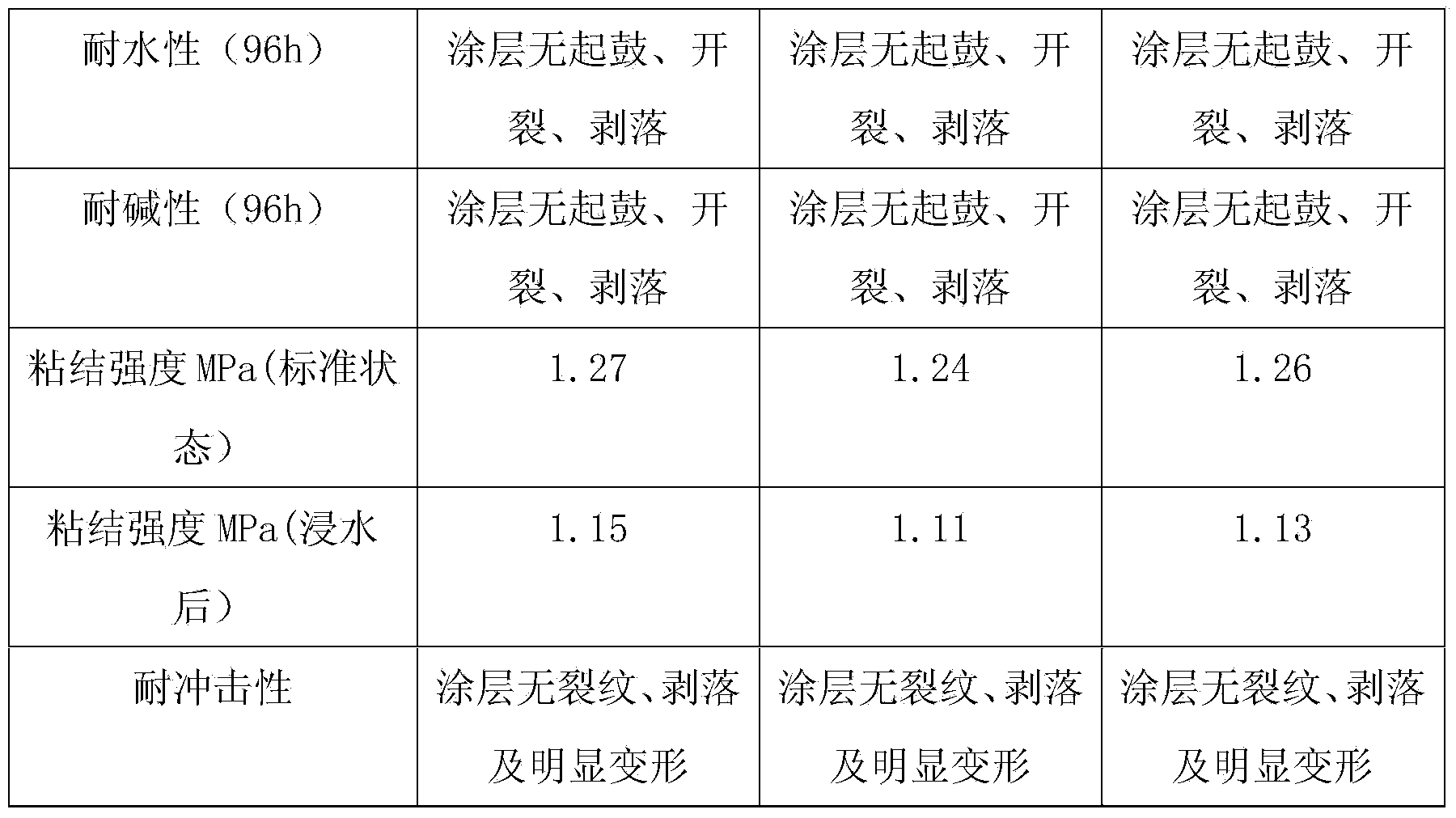

Examples

Embodiment 1

[0017] The new textured paint is prepared from the following raw materials in parts by weight: silicone acrylic emulsion 18, water-based alkyd resin 10, dispersant 0.1, wetting agent 0.1, defoamer 0.2, diethylene glycol butyl ether acetate 0.3, preservative 0.2, propylene glycol 0.5, film-forming aid 0.5, PH value regulator 0.1, magnesium aluminum silicate 0.5, calcium oxide 3, thickener 0.1, rutile titanium dioxide 4, 200 mesh quartz powder 8, kaolin 1.8-, 20-40 Mesh quartz powder 55, composite nanometer powder 5.

[0018] The preparation method of the composite nanopowder is as follows: (1) Weigh illite, hexagonite and sericite in a weight ratio of 5:4:3, mix them uniformly, calcinate at 820° C. for 2 h, cool to room temperature, and pulverize into nanopowders, Sieve; (2) Add water to the powder after sieving to make a suspension with a concentration of 40%, then add sodium polystyrene sulfonate equivalent to 4% suspension weight, 3% triethanolamine, 1.5% citric acid , 2% s...

Embodiment 2

[0020] The new textured paint is prepared from the following raw materials in parts by weight: silicone acrylic emulsion 22, water-based alkyd resin 12, dispersant 0.15, wetting agent 0.15, defoamer 0.25, diethylene glycol butyl ether acetate 0.4, preservative 0.25, propylene glycol 0.7, film-forming aid 0.8, pH regulator 0.15, magnesium aluminum silicate 0.8, calcium oxide 4, thickener 0.15, rutile titanium dioxide 5, 200 mesh quartz powder 10, kaolin 2.2, 20-40 mesh Quartz powder 58, composite nano powder 7.

[0021] The preparation method of the composite nanopowder is the same as in Example 1.

Embodiment 3

[0023] The new textured paint is prepared from the following raw materials in parts by weight: 25 parts by weight of silicone acrylic emulsion, 15 parts by weight of water-based alkyd resin, 0.2 parts of dispersant, 0.1-0.2 part of wetting agent, 0.3 part of defoamer, 0.5 part of diethylene glycol butyl ether acetate, Preservative-0.3, propylene glycol 1, film-forming aid 1, pH regulator 0.2, magnesium aluminum silicate 1, calcium oxide 6, thickener 0.2, rutile titanium dioxide 6, 200 mesh quartz powder 12, kaolin 2.5, 20 -40 mesh quartz powder 60, composite nanometer powder 10.

[0024] The preparation method of the composite nanopowder is the same as in Example 1.

[0025] The new texture paint obtained in the above examples meets the requirements of the industry, and is convenient for construction with a small dosage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com