Process of extracting white tungsten concentrate from tungstenic iron ores or tungstenic waste residues

A technology of tungsten iron ore and technology, which is applied in the field of extracting scheelite concentrate, can solve the problems of limited use, high cost, and discharge into rivers, etc., and achieve the effects of improving washing effect, reducing soda ash consumption, and having little environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Step 1: Press the pellets

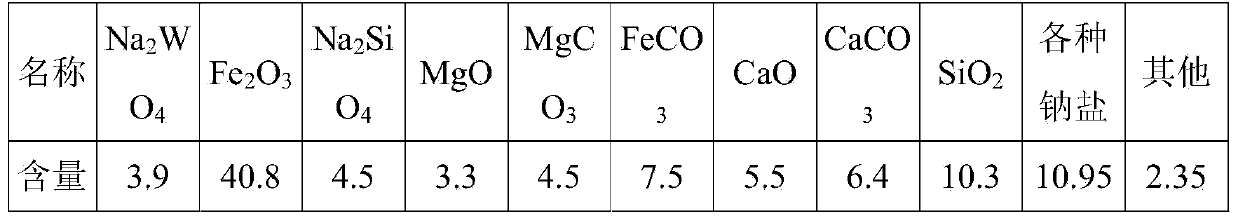

[0037] After crushing tungsten-containing iron ore powder (the specific components are shown in Table 1) into particles with a particle size of -100 mesh and a mass content of not less than 80%, mix it with soda ash, double salt and circulating tail liquid I in a mass ratio of 1:0.2 :0.15:0.2 Mix evenly, and the obtained mixture is pressed to obtain oblate pellets with a diameter of about Φ43mm.

[0038] Step 2: Roasting and leaching

[0039] Put the pellets obtained in step 1 into a vertical kiln and use gas to roast, maintain the temperature at 750°C and roast for 1.6h (the main components of the slag after roasting are shown in Table 2), after the roasted pellets are cooled, add them to the circulating tail liquid In I, at room temperature, leaching is carried out while grinding, and the mass content of solid particles is not less than 75% after grinding until the particle size is -100 mesh, and the leaching time is 1 hour; at the same ti...

Embodiment 2

[0062] Step 1: Press the pellets

[0063] After the APT slag powder (the main components are shown in Table 5) is crushed into a particle size of -100 mesh particle mass content not less than 80%, it is mixed with soda ash, double salt and circulating tail liquid I in a mass ratio of 1:0.25 :0.16:0.16 Mix evenly, and the obtained mixture is pressed to obtain oblate pellets with a diameter of about Φ45mm.

[0064] Step 2: Roasting and leaching

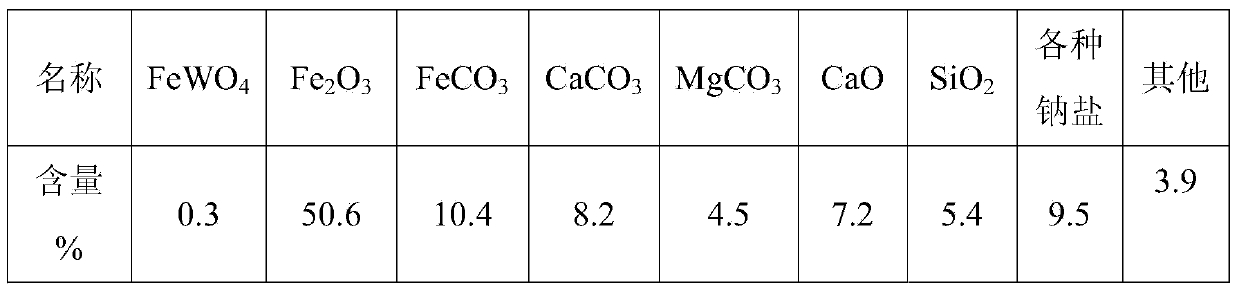

[0065] Put the pellets obtained in Step 1 into a shaft kiln and use gas to roast them, and keep them roasted at a temperature of 780°C for 1.8 hours (the main components of the slag after roasting are shown in Table 6). After the roasted pellets are cooled, add them to the circulation In the tail liquid I, at room temperature, leaching is carried out while grinding, and the mass content of solid particles is not less than 80% when the particle size is -100 mesh, and the leaching time is 1.4h; at the same time, by controlling the amount...

Embodiment 3

[0087] Step 1: Press the pellets

[0088] The reclaimed tungsten-containing catalyst (the specific components are shown in Table 9) is crushed into a particle size of -100 mesh and the mass content is not less than 80%, and the mass ratio of soda ash, double salt and circulating tail liquid I is 1:0.30: 0.16:0.25 are mixed evenly, and the obtained mixture is pressed to obtain oblate pellets with a diameter of about Φ50mm.

[0089] Step 2: Roasting and leaching

[0090] Put the pellets obtained in step 1 into a shaft kiln and use gas to roast, maintain a temperature of 800°C and roast for 1.5 hours (the main components of the slag after roasting are shown in Table 10), after the roasted pellets are cooled, add them to the circulating tail liquid In I, under room temperature conditions, leaching is carried out while grinding, and the mass content of solid particles is not less than 80% after grinding until the particle size is -100 mesh, and the leaching time is 0.8h; at the sa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com