Method for distinguishing natural colored cotton by virtue of content of flavone in colored cotton fibers

A color cotton and fiber technology, applied in the textile field, can solve the problems of high experimental cost, insignificant effect, complicated operation, etc., and achieve the effect of stable experimental results, strong operability, and optimized extraction process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

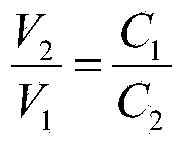

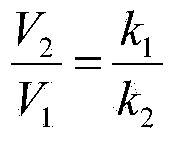

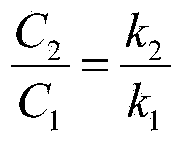

Method used

Image

Examples

Embodiment 1

[0089] Dry the pulverized brown cotton fiber to be identified at 60°C for 1 h, weigh 5.0 g of it, put it into 100 ml of 70% ethanol solution containing 0.5 g NaOH, the bath ratio is 1:20, cover and soak for 1 h, use Ultrasonic vibration and stirring, the temperature is 50°C, and the time is 1h. Suction filtration was performed twice with a suction filtration device to obtain flavonoid extract in brown cotton fiber. Take successively 0.5ml, 1.0ml, 2.0ml, 4.0ml, 6.0ml, 8.0ml of the flavonoid extracts in brown cotton fibers prepared by the above steps, and place them in six 25ml volumetric flasks, and add the concentration 5% NaNO 2 Solution 2.5ml, mix well, let stand for 5min; then add concentration is 10% Al(NO 3 ) 3 Solution 3.5ml, mix well, let stand for 5min; then add 5ml of NaOH solution with a concentration of 2mol / L, mix well, let stand for 5min, finally add 70% ethanol solution to make up to 25ml, mix well, seal and cover. The absorbance of the solution after color d...

Embodiment 2

[0091] Dry the pulverized brown cotton fiber to be identified at 60°C for 1 hour, weigh 3.33g of it, put it into 100ml of 60% ethanol solution containing 1.0g of NaOH, the bath ratio is 1:30, cover and soak for 1 hour, use Ultrasonic vibration and stirring, the temperature is 40°C, and the time is 1h. Suction filtration was performed twice with a suction filtration device to obtain flavonoid extract in brown cotton fiber. Take successively 0.5ml, 1.0ml, 2.0ml, 4.0ml, 6.0ml, 8.0ml of the flavonoid extracts in brown cotton fibers prepared by the above steps, and place them in six 25ml volumetric flasks, and add the concentration 5% NaNO 2 Solution 2.5ml, mix well, let stand for 5min; then add concentration is 10% Al(NO 3 ) 3 Solution 3.5ml, mix well, let stand for 5min; then add 3ml of NaOH solution with a concentration of 2mol / L, mix well, let stand for 5min, finally add 60% ethanol solution to make up to 25ml, mix well, seal and cover. Test the absorbance of the solution a...

Embodiment 3

[0093] Dry the pulverized brown cotton fiber to be identified at 60°C for 1 h, weigh 2.5 g of it, put it into 100 ml of 80% ethanol solution containing 1.5 g of NaOH, the bath ratio is 1:40, cover and soak for 1 h, use Ultrasonic vibration and stirring, the temperature is 60°C, and the time is 1h. Suction filtration was performed twice with a suction filtration device to obtain flavonoid extract in brown cotton fiber. Take successively 0.5ml, 1.0ml, 2.0ml, 4.0ml, 6.0ml, 8.0ml of the flavonoid extracts in brown cotton fibers prepared by the above steps, and place them in six 25ml volumetric flasks, and add the concentration 5% NaNO 2 Solution 3.5ml, mix well, let stand for 5min; then add concentration is 10% Al(NO 3 ) 3 Solution 4.5ml, mix well, let stand for 5min; then add 8ml of NaOH solution with a concentration of 2mol / L, mix well, let stand for 5min, finally add 80% ethanol solution to dilute to 25ml, mix well, seal and cover. Test the absorbance of the solution after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com