Titanium oxide multilayer thin film varistor and preparation method for same

A technology of varistors and multi-layer thin films, applied in the direction of coating resistance materials, coatings, metal material coating processes, etc., can solve the difficulty of miniaturization of varistors, varistors without titanium oxide films, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

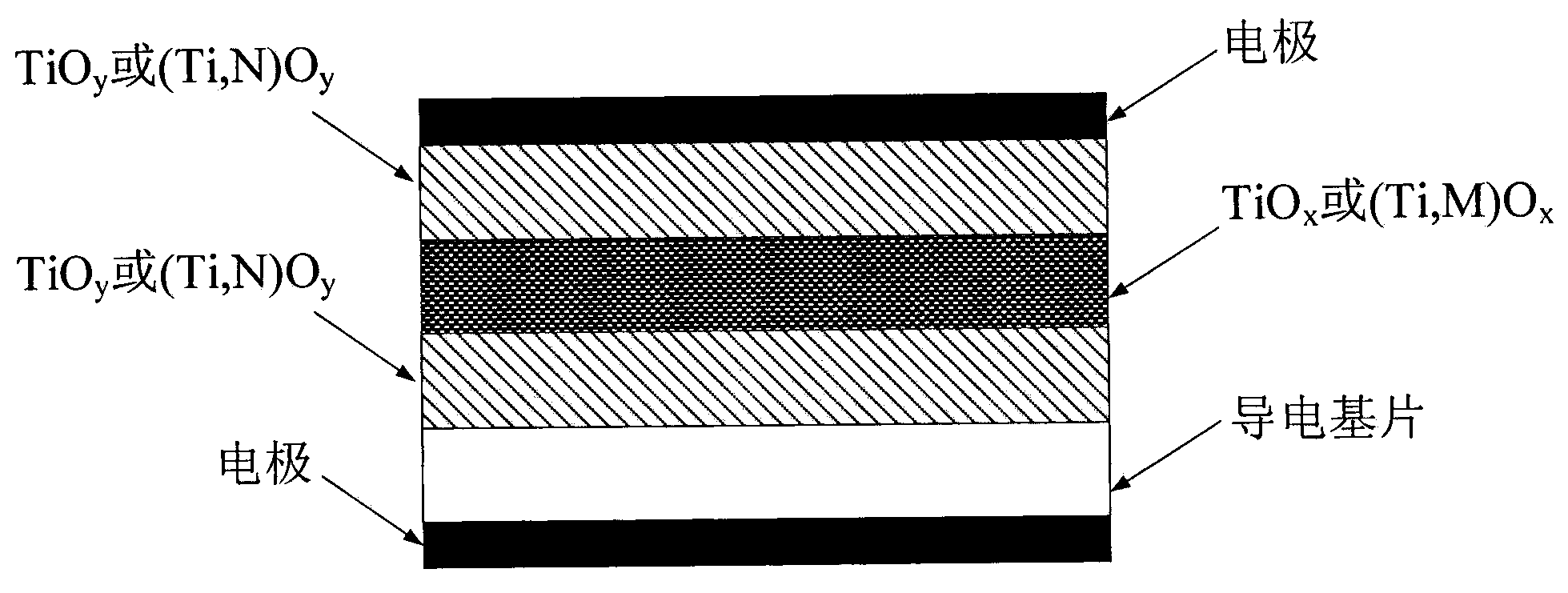

[0036] The present invention also proposes a preparation method of this titanium oxide multilayer film varistor, which is characterized in that the method uses non-stoichiometric sintered TiO m As a matrix target, other metals or their oxides are doped targets. By radio frequency magnetron sputtering, under the action of carrier gas, TiO y -TiO x -TiO y (y>x) A thin film varistor with a sandwich structure as the basic unit. The method deposits titanium oxide film piezoresistors of different compositions on a conductive substrate by radio frequency reactive magnetron sputtering, comprising the following steps and contents:

[0037] (1) In the magnetron sputtering equipment, sintered TiO with non-stoichiometric ratio m (m=1.1-1.8) is used as the matrix target, and other metals or their oxides are doped targets. Fix different targets on different target positions, and fix the clean substrate on the sample stage; turn on the mechanical pump to Low vacuum, system vacuum up to 1...

Embodiment 1

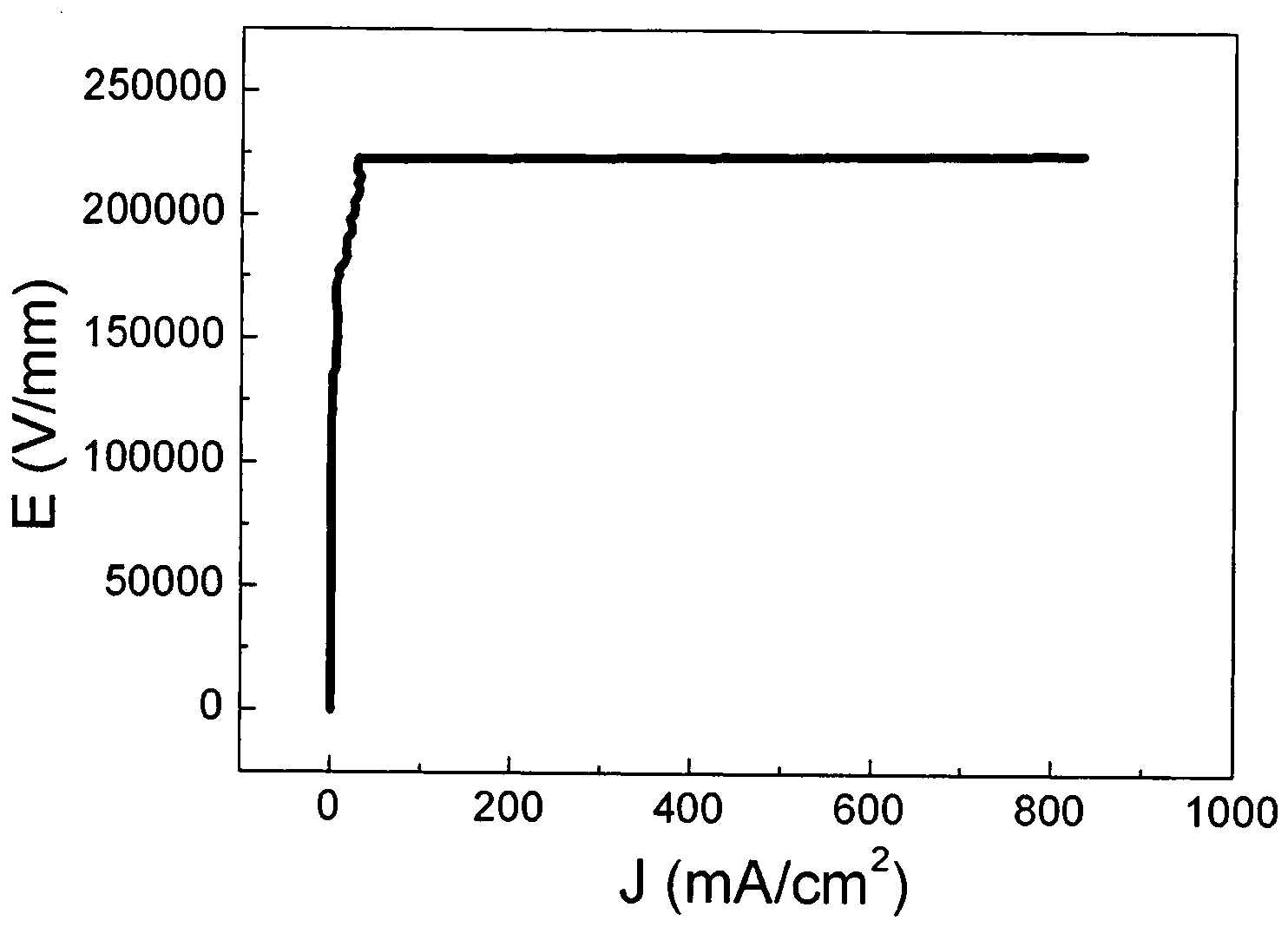

[0052] Embodiment 1: TiO 1.3 The target and the clean highly doped conductive silicon substrate are fixed on the corresponding positions of the magnetron sputtering equipment, the chamber is closed, and the mechanical pump is first turned on to draw to a low vacuum of 10 -1 Pa, then turn on the molecular pump to pump to a high vacuum of 2×10 -4 Pa. Introduce high-purity argon gas, and pre-sputter for 10 minutes. Then pass through the Ar / O 2 The mixed gas ratio is 4:1, and the sputtering power is 60W, and the deposition is performed for 1 hour. Close the oxygen valve, only pass argon gas, and deposit for 1 hour under the condition of sputtering power of 60W. Inject Ar / O again 2 The mixed gas ratio is 4:1, and the sputtering power is 60W, and the deposition is performed for 1 hour. can be obtained on the substrate containing a TiO y -TiO x -TiO y Undoped multilayer films of structural units. The whole process is carried out at room temperature, and the working pressure...

Embodiment 2

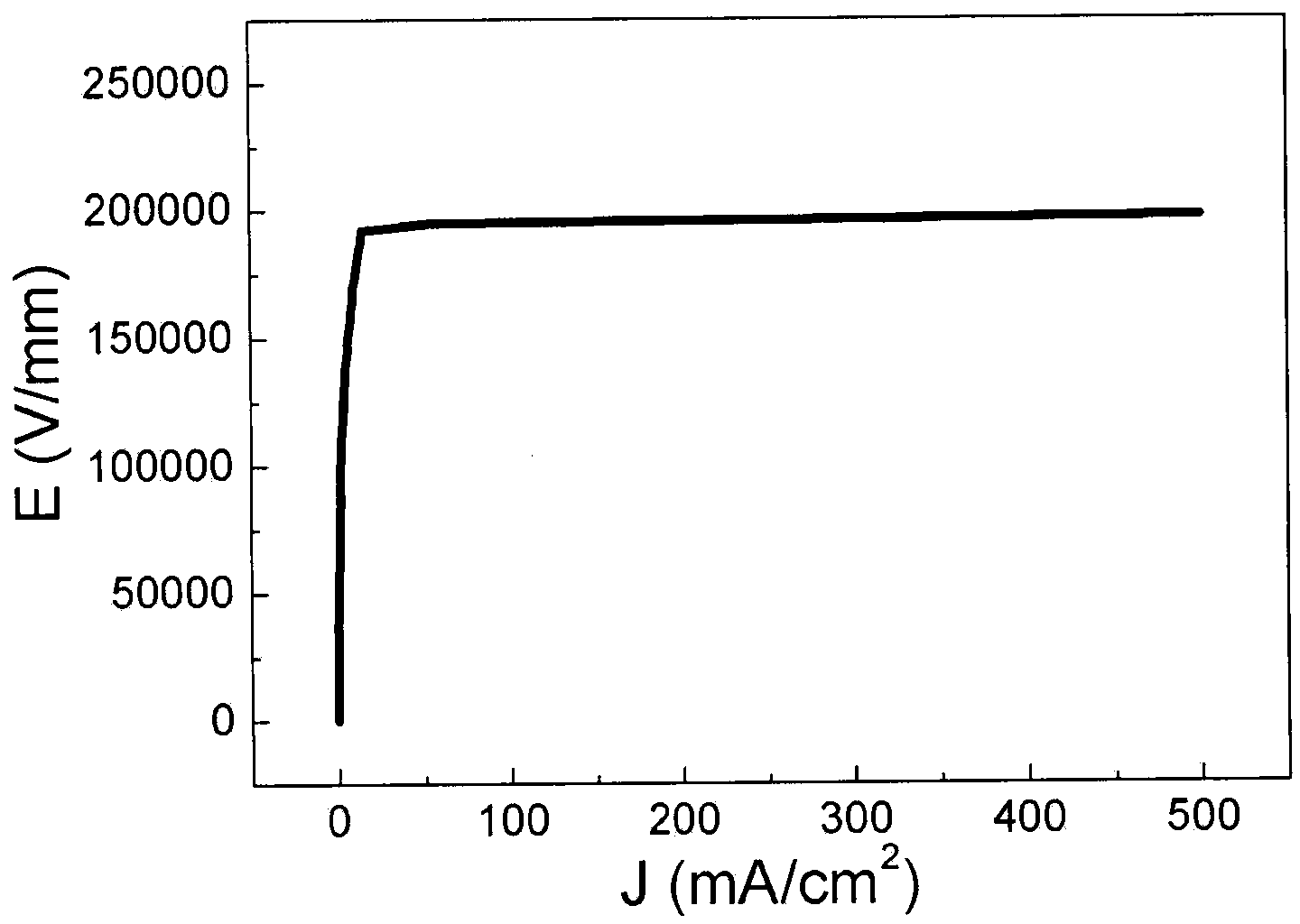

[0053] Embodiment 2: TiO 1.3 The target and the clean highly doped conductive silicon substrate are fixed on the corresponding positions of the magnetron sputtering equipment, the chamber is closed, and the mechanical pump is first turned on to draw to a low vacuum of 10 -1 Pa, then turn on the molecular pump to pump to a high vacuum of 2×10 -4 Pa. Introduce high-purity argon gas, and pre-sputter for 10 minutes. Then pass through the Ar / O 2 The mixed gas ratio is 4:1, and the sputtering power is 60W, and the deposition is performed for 1 hour. Close the oxygen valve, only pass argon gas, and deposit for 1 hour under the condition of sputtering power of 60W. Inject Ar / O again 2 The mixed gas ratio is 4:1, and the sputtering power is 60W, and the deposition is performed for 1 hour. Close the oxygen valve again, only flow argon, and deposit for 1 hour under the condition of sputtering power of 60W. Then pass through the Ar / O 2 The mixed gas ratio is 4:1, and the sputterin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com