Graphene for electrical double-layer capacitor and preparation method thereof

A supercapacitor battery and graphene technology, which is applied in the manufacture of hybrid capacitor electrodes and hybrid/electric double layer capacitors, etc., can solve the problems of low specific surface area utilization rate, poor conductivity, and inability to effectively form an electric double layer, and achieve low cost. , Improve the specific capacitance value, improve the stability and purity of the crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

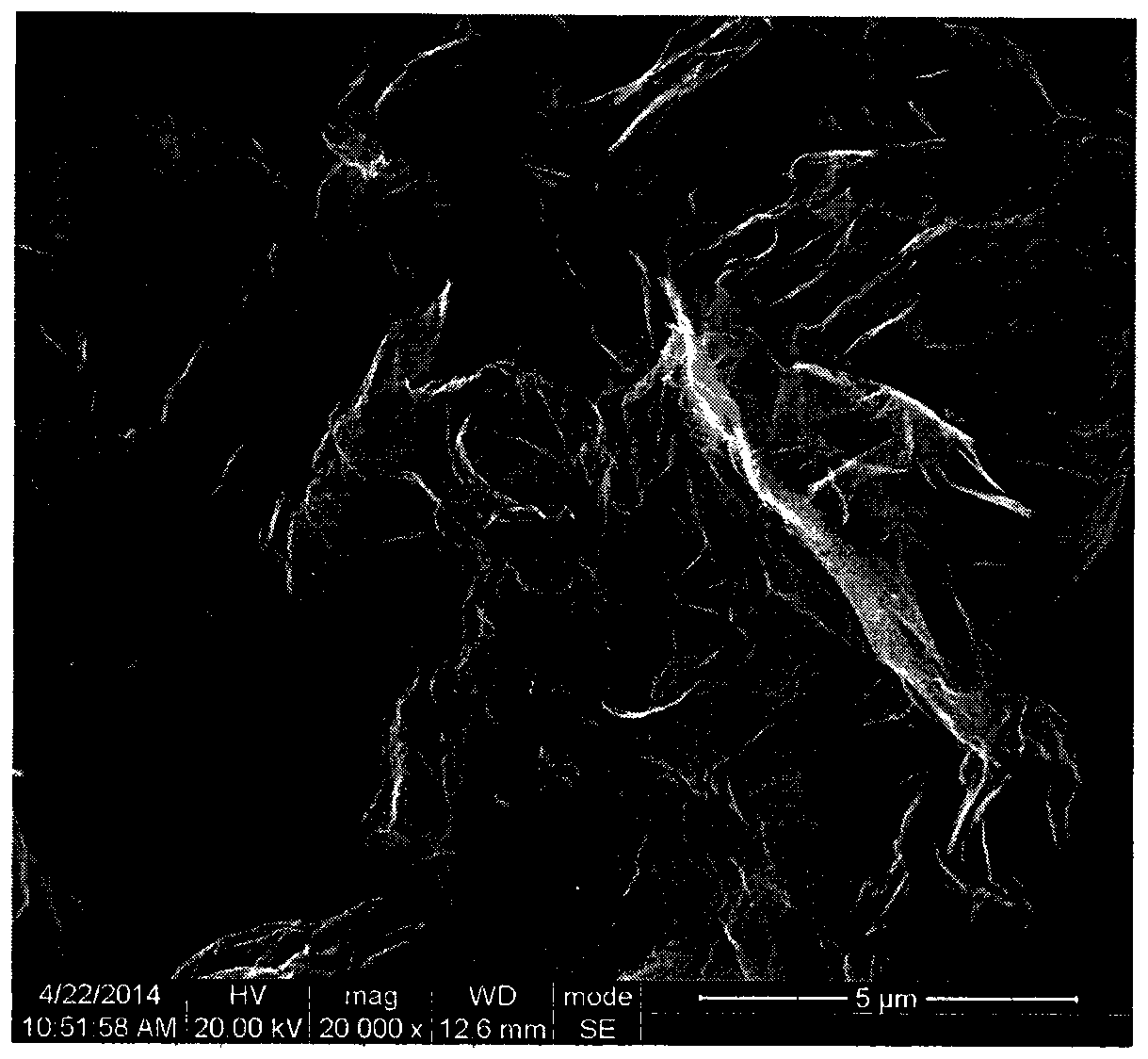

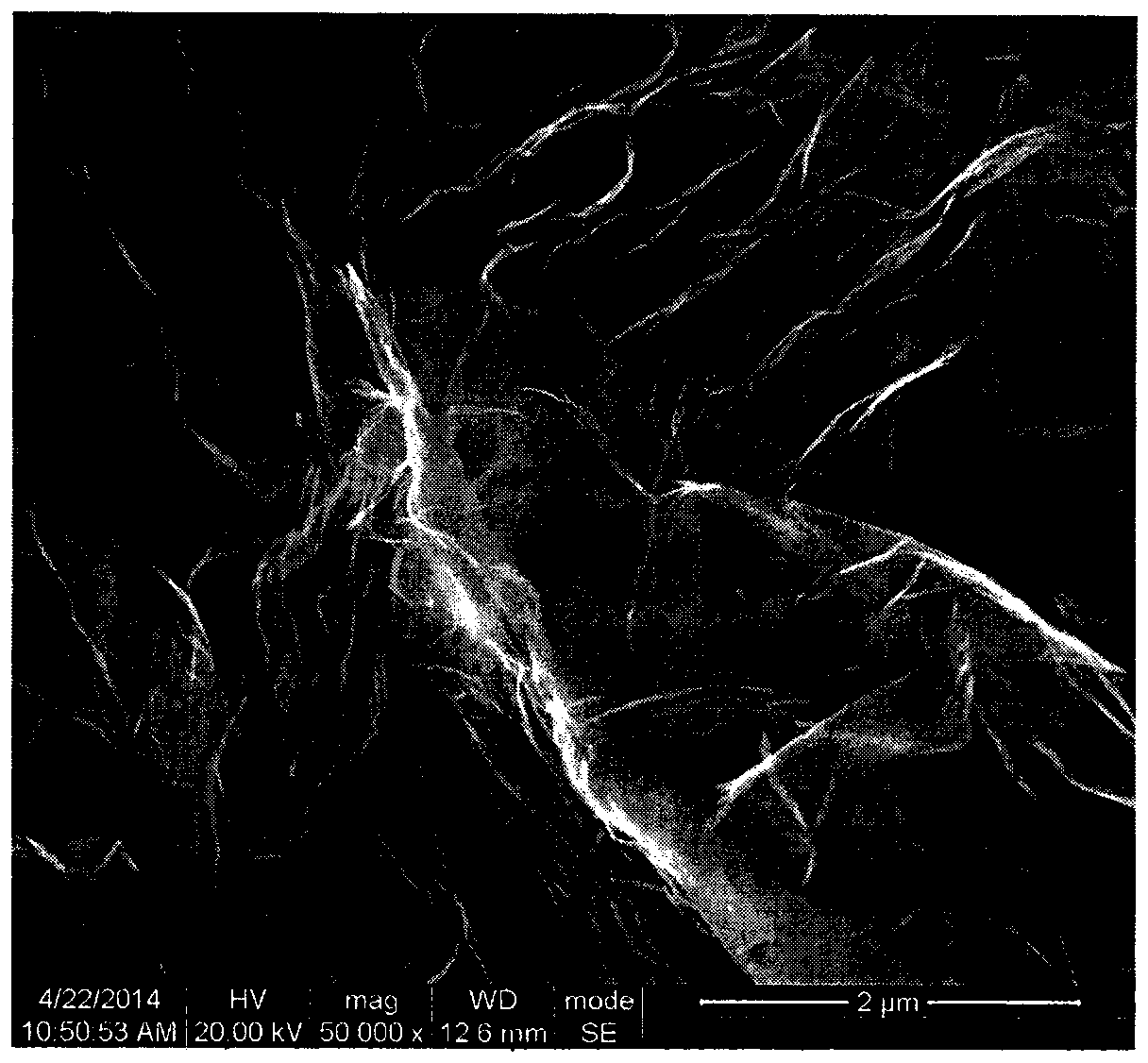

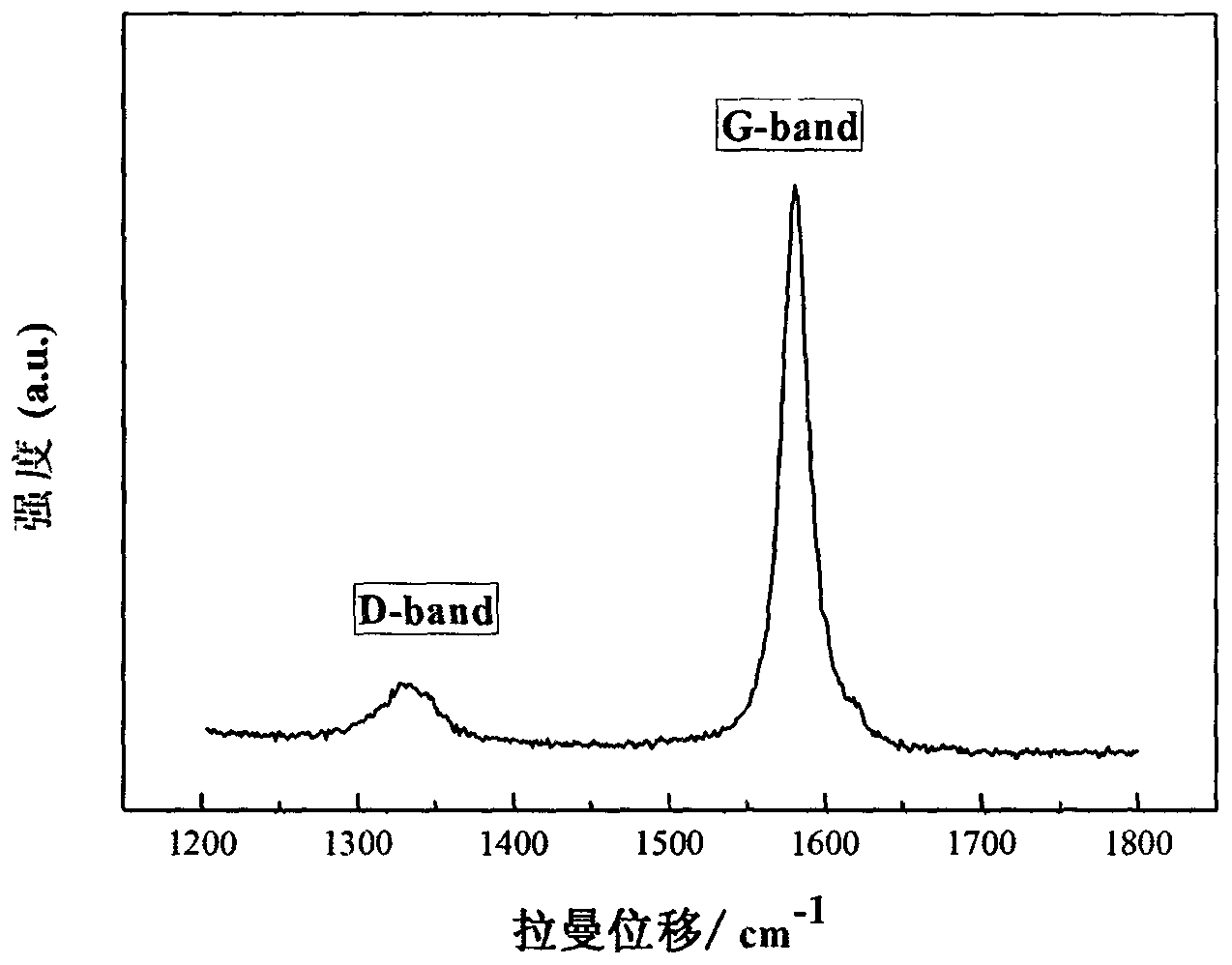

[0031] Weigh 5.0g flake graphite, 2.5g potassium nitrate, 15.0g potassium permanganate and mix them evenly, place them in a special reaction kettle, then add 115mL of concentrated sulfuric acid, react at a low temperature of 4°C for 24h, at a medium temperature of 40°C for 4h, at a high temperature of 90°C Three stages of reaction 30min. Then add 75mL of hydrogen peroxide into the above reaction device, after fully reacting, pickling, water washing and drying to obtain graphite oxide. The graphene product of the present invention is obtained after graphite oxide is expanded and reduced in air at 450° C. for 30 minutes. The specific surface area of the prepared graphene is about 456m 2 / g. Mix the above-mentioned graphene with binder and conductive carbon black evenly (the mass ratio of each component is 90:5:5), coat it on the nickel foam, dry it, and cut it into a disc with a diameter of 1.0cm, as the sample to be tested. Electrodes are used where the active material loa...

example 2

[0033]Weigh 20.0g of graphite flakes, 10.0g of potassium nitrate, and 60.0g of potassium permanganate and mix them evenly, place them in a special reaction kettle, then add 460mL of concentrated sulfuric acid, and undergo a reaction at a low temperature of 4°C for 24 hours, a medium temperature of 40°C for 4 hours, and a high temperature of 90°C Three stages of reaction 30min. Then add 300mL of hydrogen peroxide into the above reaction device, after fully reacting, pickling, washing with water, and drying to obtain graphite oxide. The graphite oxide is expanded and reduced in air at 300° C. for 30 minutes to obtain the graphene product of the present invention. The specific surface area of the prepared graphene is about 440m 2 / g. Mix the above-mentioned graphene with binder and conductive carbon black evenly (the mass ratio of each component is 90:5:5), coat it on the nickel foam, dry it, and cut it into a disc with a diameter of 1.0cm, as the sample to be tested. Electr...

example 3

[0035] Weigh 150.0g flake graphite, 75.0g potassium nitrate, 450.0g potassium permanganate and mix them evenly, put them in a special reaction kettle, then add 3450mL concentrated sulfuric acid, react at low temperature 4°C for 24h, medium temperature at 40°C for 4h, high temperature at 90°C Three stages of reaction 30min. Then add 2250mL hydrogen peroxide into the above reaction device, after fully reacting, pickling, water washing and drying to obtain graphite oxide. The graphene product of the present invention is obtained after graphite oxide is expanded and reduced in air at 350° C. for 30 minutes. The specific surface area of the prepared graphene is about 432m 2 / g. Mix the above-mentioned graphene with binder and conductive carbon black evenly (the mass ratio of each component is 90:5:5), coat it on the nickel foam, dry it, and cut it into a disc with a diameter of 1.0cm, as the sample to be tested. Electrodes are used where the active material loading is greater ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com