Preparation method for dibutyl adipate

A technology of dibutyl adipate and adipic acid, which is applied to the preparation of carboxylic acid esters, the preparation of organic compounds, chemical instruments and methods, etc., can solve the problems of low esterification rate and long synthesis reaction time, and achieve reagent Safety, increase the reaction esterification rate, reduce the effect of reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] The invention discloses a preparation method of dibutyl adipate, and those skilled in the art can refer to the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar substitutions and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

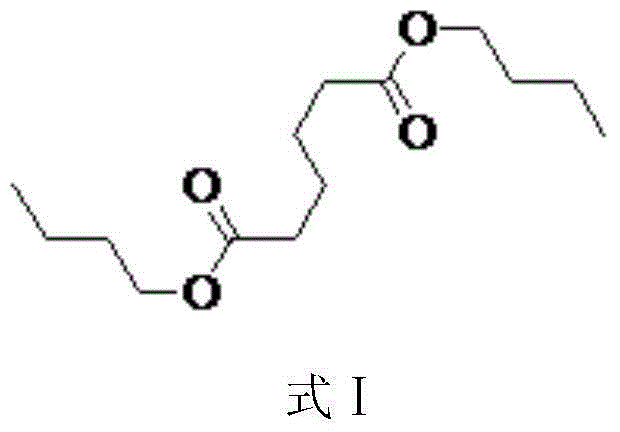

[0013] The invention provides a method for preparing dibutyl adipate, a compound whose structure is shown in formula I. FeCl 3 ·6H 2 O is a catalyst, and adipic acid and n-butanol are synthesized un...

Embodiment 1

[0020] The influence of embodiment 1 microwave on reaction

[0021] with FeCl 3 ·6H 2 O is a catalyst, with adipic acid and n-butanol as raw materials, esterification reaction occurs under the conditions of conventional heating and microwave radiation heating respectively, and the reaction time and reaction esterification rate are analyzed. The results are shown in Table 1:

[0022] Table 1 Effect of conventional heating and microwave radiation heating on the reaction

[0023]

[0024] Wherein, the calculation of esterification rate is calculated according to the following formula:

[0025]

[0026] The data in Table 1 shows that by using FeCl 3 ·6H 2 O was used as a catalyst, adipic acid and n-butanol were used as raw materials, and the synthesis reaction occurred under the condition of microwave radiation heating. The reaction time was shortened to 30 minutes, and the esterification rate was increased to 89.1%. In the synthesis reaction of dibutyl adipate, microwa...

Embodiment 2

[0027] The preparation of embodiment 2 dibutyl adipate

[0028] With 1.46g (0.01mol) adipic acid, 29.6g (0.4mol) n-butanol, 2.0g (0.007mol) FeCl 3 ·6H 2 O Equipped with a water separator, a thermometer and a reflux condenser in a three-necked quartz flask, dissolve the tape and shake it evenly, take a sample to measure its acid value, place it in a modified microwave reactor, and react with a microwave radiation power of 130w for 30min, then take a sample to measure its acid value after cooling down slightly Acid value, neutralize the reaction solution to weak acidity, then wash with water, dilute sodium carbonate and water respectively, dry and distill, distill n-butanol at normal pressure, distill under reduced pressure to obtain 2.29g of dimethyl adipate, The esterification rate is 88.8%, and the refractive index is 1.432 (25°C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| esterification rate | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com