Method for preparing stealthy fabric with double functions of radar stealth and infrared stealth

A radar stealth, dual-function technology, applied in the field of absorbing materials, can solve problems such as unsatisfactory bonding fastness, achieve good visible light stealth effect, and improve the effect of bonding fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

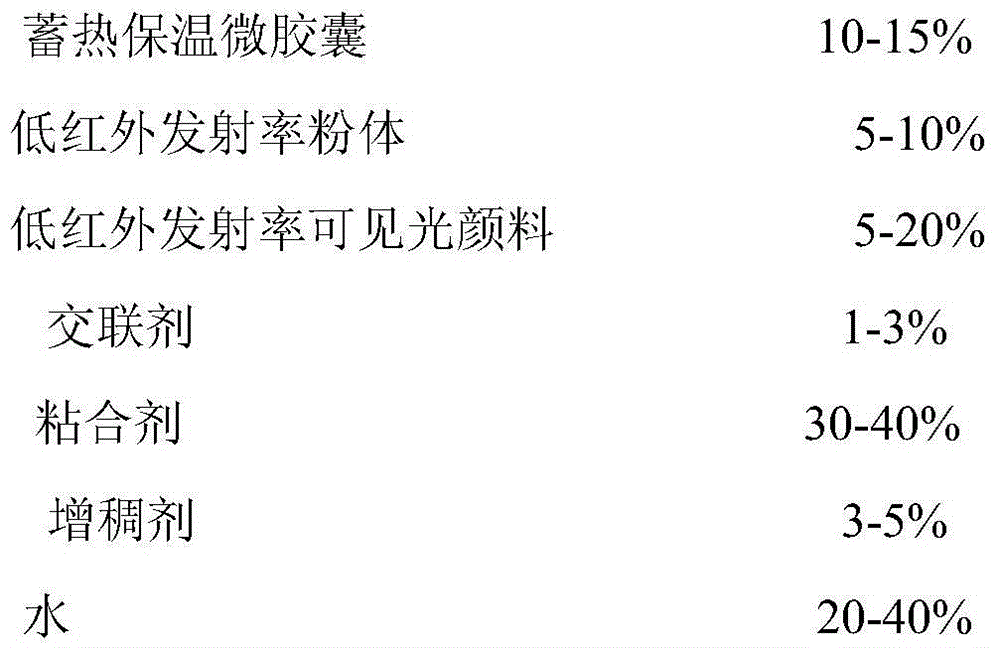

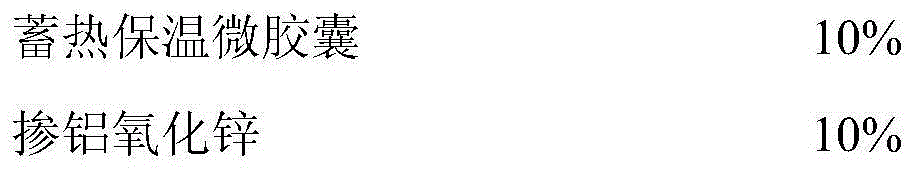

Method used

Image

Examples

Embodiment 1

[0031] (1) Cotton fabric is placed on the shelf in the chamber of DT-01 low-temperature plasma processing machine (Suzhou Opus Plasma Technology Co., Ltd.), and the vacuum pump is turned on. When the vacuum in the reaction chamber is 5Pa, oxygen is introduced. , adjust the flow rate of oxygen until the vacuum degree in the reaction chamber is 20Pa, glow discharge (discharge power 100W, discharge time 10min), after the discharge is over, turn off the oxygen switch, feed acrylic acid monomer steam, under the vacuum degree of 30Pa, glow discharge Light discharge (discharge power 50W, discharge time 30min), after discharge, deionized water ultrasonic cleaning 3 times, 50 ℃ drying, standby;

[0032] (2) Add aniline monomer to 0.5mol / L hydrochloric acid solution to prepare 1mol / L aniline solution, heat the aniline hydrochloric acid solution to 50°C, and add the aniline treated in step (1) at a bath ratio of 1:20 For textiles, after soaking for 120 minutes, take them out, roll them a...

Embodiment 2

[0042] (1) Cotton fabric is placed on the shelf in the chamber of DT-01 low-temperature plasma processing machine (Suzhou Opus Plasma Technology Co., Ltd.), and the vacuum pump is turned on. When the vacuum in the reaction chamber is 5Pa, oxygen is introduced. , adjust the flow rate of oxygen until the vacuum degree in the reaction chamber is 60Pa, glow discharge (discharge power 250W, discharge time 5min), after the discharge is over, turn off the oxygen switch, and feed the methacrylic acid monomer vapor, under the vacuum degree of 50Pa , glow discharge (discharge power 150W, discharge time 10min), after discharge, deionized water ultrasonic cleaning 5 times, 80 ℃ drying, standby;

[0043] (2) adding the aniline monomer (98% of the mass fraction of the aniline monomer, and 2% of the mass fraction of m-phenylenediamine) into a 2mol / L sulfuric acid solution to prepare a 2.5mol / L aniline monomer solution, Heating the sulfuric acid solution of aniline monomers to 80°C, adding th...

Embodiment 3

[0052] (1) Cotton fabric is placed on the shelf in the chamber of DT-01 low-temperature plasma processing machine (Suzhou Opus Plasma Technology Co., Ltd.), and the vacuum pump is turned on. When the vacuum in the reaction chamber is 5Pa, oxygen is introduced. , adjust the flow rate of oxygen until the vacuum degree in the reaction chamber is 40Pa, glow discharge (discharge power 150W, discharge time 8min), after the discharge is over, turn off the oxygen switch, and feed the methacrylic acid monomer vapor, under the vacuum degree of 40Pa , glow discharge (discharge power 100W, discharge time 20min), after discharge, deionized water ultrasonic cleaning 4 times, 60 ℃ drying, standby;

[0053] (2) Add aniline monomers (96% of the mass fraction of aniline monomers, 4% o-phenylenediamine) into 1mol / L nitric acid solution, prepare 2mol / L aniline monomer solutions, and aniline monomers The nitric acid solution is heated to 70°C, and the textiles treated in step (1) are added in a ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Reflectivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com