Alfalfa bundling and wrapping ensiling method

An alfalfa and silage technology, which is applied to the processing field of alfalfa baling and silage and alfalfa silage, can solve the problems of low cellulose decomposition ability, affecting the utilization of crude fiber, and lack of decomposition ability, etc., and achieves fermentation effect, quality improvement and prevention. and the effect of treating common diseases of livestock and reducing dry matter loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

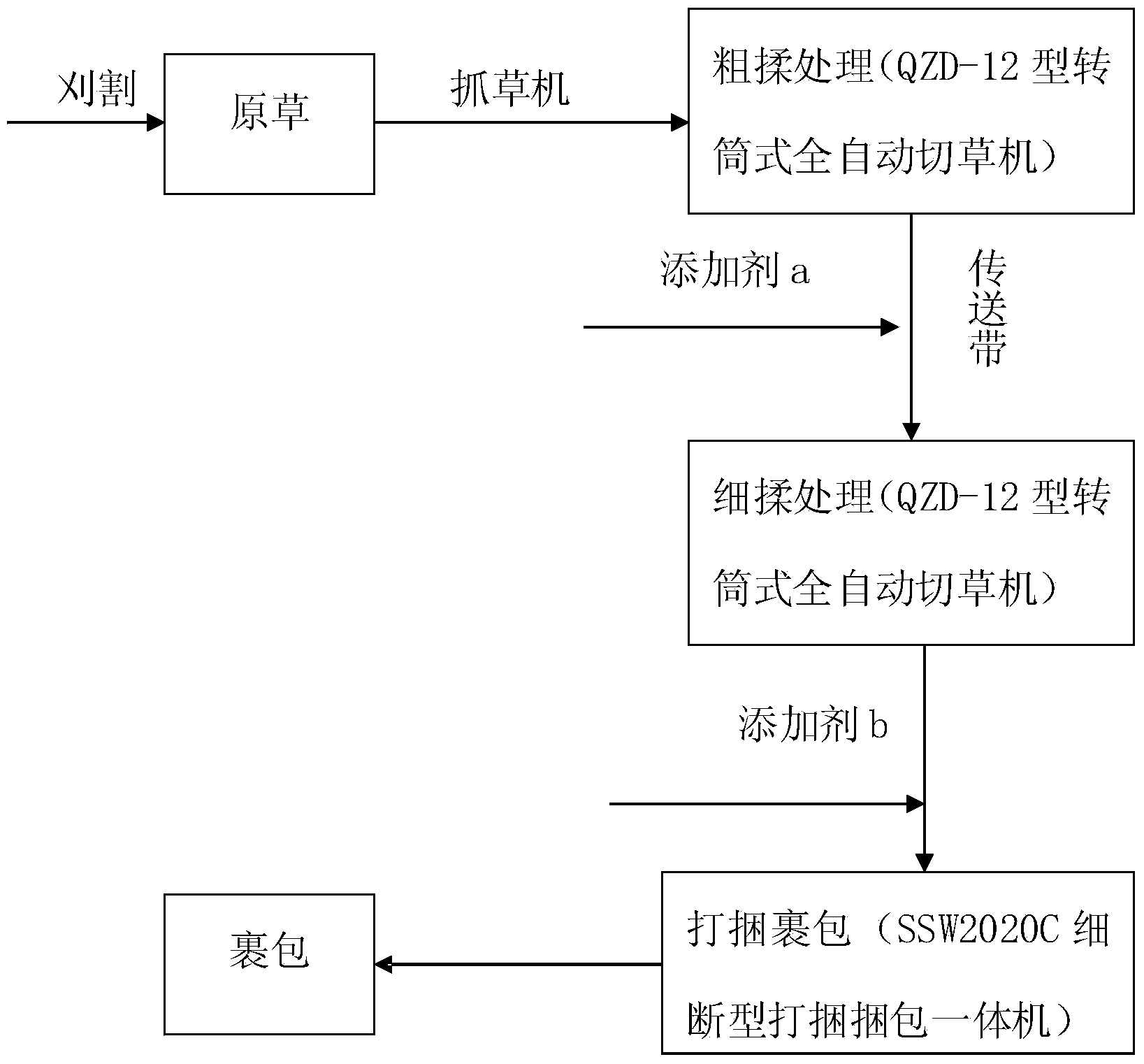

[0036] A method for baling and wrapping alfalfa silage, comprising the following processing steps:

[0037] ⑴Preparation of special silage additive for alfalfa

[0038] ①Preparation of additive a: Mix 3kg of Acanthopanax, 3kg of Schisandra, and 6kg of Astragalus into a Chinese medicine composition, add 30kg of water, soak the liquid surface with Chinese medicine, place it at 4°C for 24h, extract at 70°C for 30min, and filter After that, add 30kg of water, extract at 80°C for 40min, filter again, mix the medicinal liquid after the two filtrations, and concentrate it to 12L at 75°C to obtain 1g / ml Chinese medicinal liquid, add selenium content to it. 2.727g of 44% sodium selenite to make the concentration of selenium reach 1mg / ml, stir evenly, seal, and store at 4°C;

[0039] ②Preparation of additive b: Mix 6g of Streptococcus thermophilic lactis, 4g of Pediococcus lactis, 3g of Pediococcus pentosaceae, and 3g of Bacillus subtilis into a mixed bacterial powder; mix 24g of cellu...

Embodiment 2

[0049] A method for baling and wrapping alfalfa silage, comprising the following processing steps:

[0050] ⑴Preparation of special silage additive for alfalfa

[0051] ①Preparation of additive a: Mix 3.5kg of Acanthopanax, 3.5kg of Schisandra, and 7kg of Astragalus into a traditional Chinese medicine composition, add 35kg of water, soak the liquid surface with Chinese medicine, place it at 4°C for 24h, then extract at 70°C for 30min , after filtering, add 35kg of water, extract at 80°C for 40min, then filter again, mix the liquid medicine after two times of filtration, and concentrate to 14L at 75°C to obtain 1g / ml Chinese medicine liquid, add selenium to it Content is 3.1815g of sodium selenite of 44%, make the concentration of selenium reach 1mg / ml, stir evenly, seal, place under the condition of 4 ℃ and preserve;

[0052] ②Preparation of additive b: Mix 8 g of Streptococcus thermophilic lactis, 3 g of Pediococcus lactis, 1 g of Pediococcus pentosaceae, and 4 g of Bacillus...

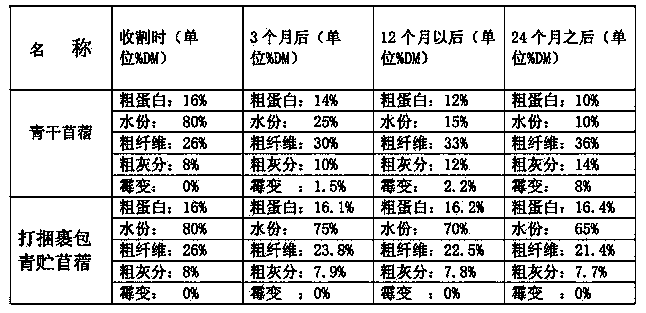

experiment example

[0062] The packaged silage alfalfa feed processed in Example 2 was compared with the common dry alfalfa feed, and the crude protein content, moisture content, crude fiber content, crude ash content and mildew degree of each storage period were measured respectively.

[0063] Experimental measurement data records, as shown in the following table:

[0064]

[0065] Through the comparative analysis of the data, the results show that the components of alfalfa can basically maintain the same quality after being baled and wrapped for silage, and the influence of external factors is small, while the nutritional components of alfalfa hay change greatly, and its nutritional components lose greatly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

| Viable count | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com