Compound oxidant for advanced treatment of electroplate phosphorate wastewater and wastewater treatment method

An advanced treatment and oxidant technology, which is applied in the direction of oxidized water/sewage treatment, metallurgical wastewater treatment, water/sludge/sewage treatment, etc., can solve the problems of poor phosphorus removal effect, achieve good oxidation effect, avoid adverse effects, and realize Effects of Environmental Benefits and Social Benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

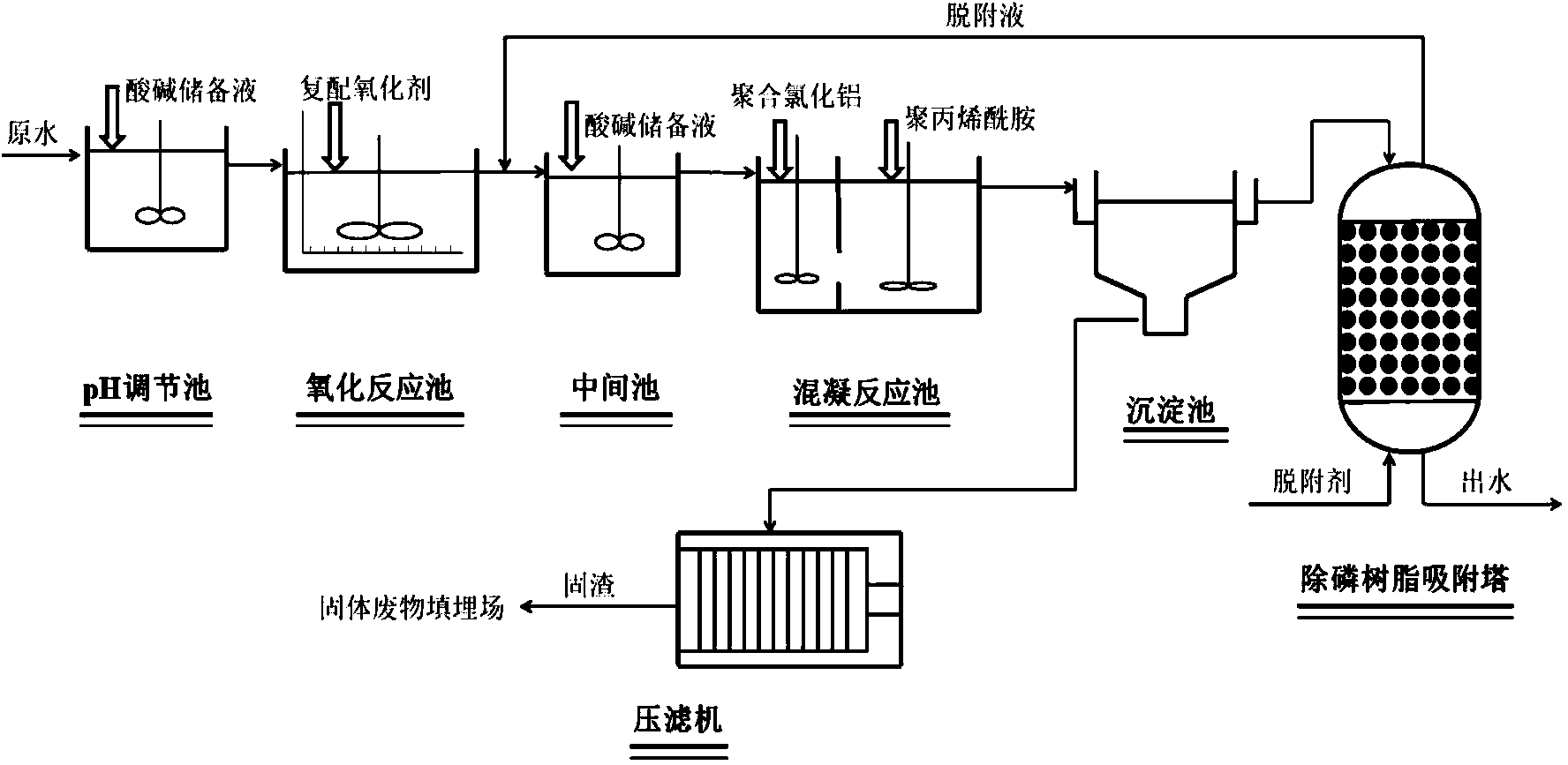

[0041] combined with figure 1 , a compound oxidant and wastewater treatment method for advanced treatment of electroplating phosphorus-containing wastewater in this embodiment is especially suitable for treating electroplating phosphorus-containing wastewater with high non-orthophosphate content. The steps are:

[0042] (A) Control electroplating phosphorus-containing wastewater to enter the pH adjustment tank. In this experiment, the electroplating phosphorus-containing wastewater in this example has a total phosphorus content of 54.3 mg / L, an orthophosphate content of 8.54 mg / L, and a pH of 4. Using 30% sodium hydroxide stock solution to adjust the pH of wastewater to 9;

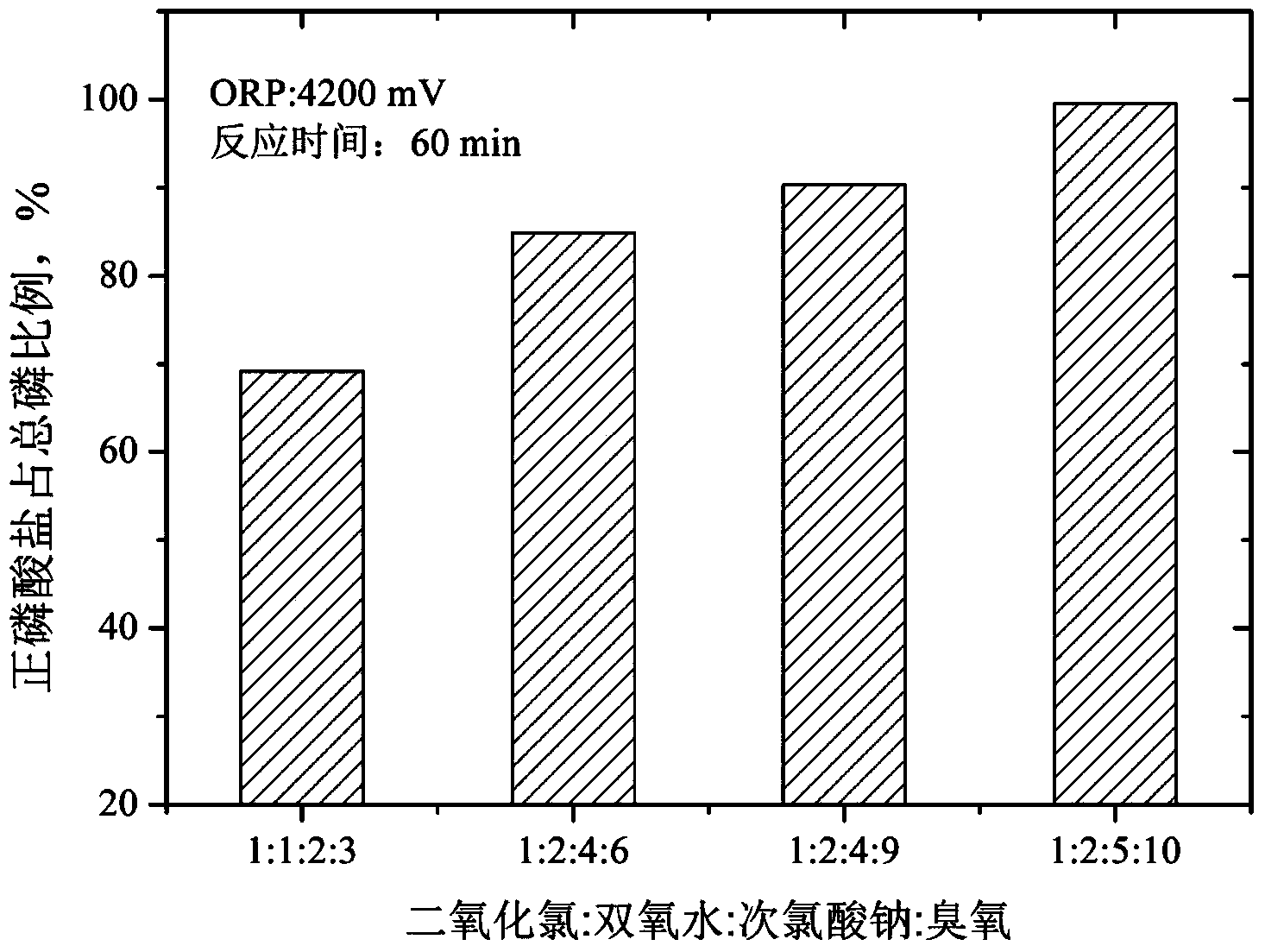

[0043] (B) The effluent obtained in step (A) is entered into the oxidation reaction contact tank, and a metering pump is used to add three kinds of solution oxidants of chlorine dioxide, hydrogen peroxide and sodium hypochlorite simultaneously, and an aeration method is adopted to add ozone gas oxidant, a...

Embodiment 2

[0053] A method for advanced treatment of electroplating phosphorus-containing wastewater in this embodiment is basically the same as in Embodiment 1, except that some parameters are adjusted, and the same effect can still be achieved. details as follows:

[0054] In step (A), 30% sodium hydroxide stock solution is added to adjust the pH of the wastewater to 8.

[0055] The ratio of the compound oxidant added in the step (B) is chlorine dioxide: hydrogen peroxide: sodium hypochlorite: ozone=1:1:3:5, the ORP of the control wastewater is 3500mV, the mechanical stirring rate is 180rpm, and the reaction time is 60min.

[0056] In step (C), add 30% sodium hydroxide stock solution to adjust the pH to 8.5.

[0057] In step (D), the stirring speed of adding polyaluminum chloride is 60 rpm, and the reaction time is 15 minutes; the stirring speed of adding polyacrylamide is 60 rpm, and the reaction time is 60 minutes. The mass percent concentration of coagulant polyaluminum chloride s...

Embodiment 3

[0063] A method for advanced treatment of electroplating phosphorus-containing wastewater in this embodiment is basically the same as in Embodiment 1, except that some parameters are adjusted, and the same effect can still be achieved. details as follows:

[0064] In step (A), 30% sodium hydroxide stock solution is added to adjust the pH of the wastewater to 8.3.

[0065] The ratio of the compound oxidant added in the step (B) is chlorine dioxide: hydrogen peroxide: sodium hypochlorite: ozone=1:2:3:5, the ORP of the control wastewater is 3800mV, the mechanical stirring rate is 120rpm, and the reaction time is 60min.

[0066] In step (C), add 30% sodium hydroxide stock solution to adjust the pH to 8.5.

[0067] In step (D), the stirring speed of adding polyaluminum chloride is 120rpm, and the reaction time is 30min; 10%, the dosage of polyaluminum chloride solution is 1L / m 3 ; The dosage of polyacrylamide solution is 3L / m 3 , the mass percent concentration of the polyacryla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com