A kind of preparation method of carbon nanofiber nitride type conductive polymer composite material with high specific capacity and low leakage current

A technology of carbon nanofibers and conductive polymers, which is applied in the field of carbon materials and chemical power sources, can solve problems such as unknown influences, achieve the effects of increasing nitrogen content, low leakage current, and avoiding irreversible stacking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

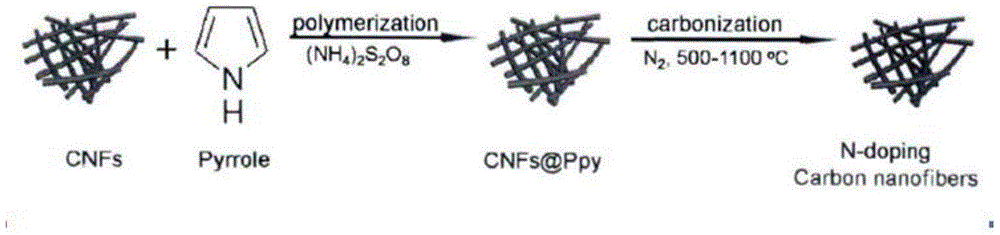

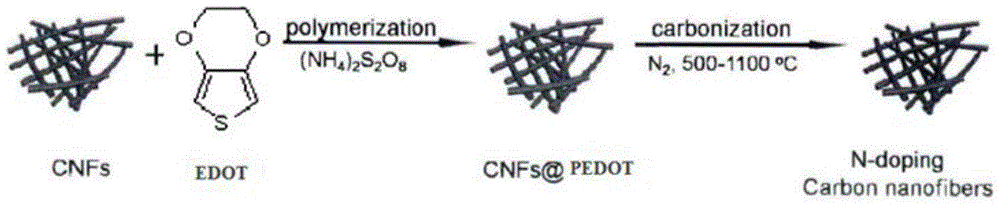

[0067] The preparation method of a carbon nanofiber nitrided conductive polymer composite material with high specific capacity and low leakage current provided in this embodiment specifically includes:

[0068] 1) Weigh with JA2003N electronic balance (Shanghai Precision Scientific Instrument Co., Ltd.), the water-soluble carboxylated graphene powder is formulated into suspoemulsion A with a content of 2-3%, and CHJ-1 constant temperature magnetic stirrer (Shanghai Nanhui Telecom Apparatus factory) stir evenly, and equal amount is divided into three parts for subsequent use, and the content of the preferred water-soluble carboxylated graphene of the present embodiment is 2%;

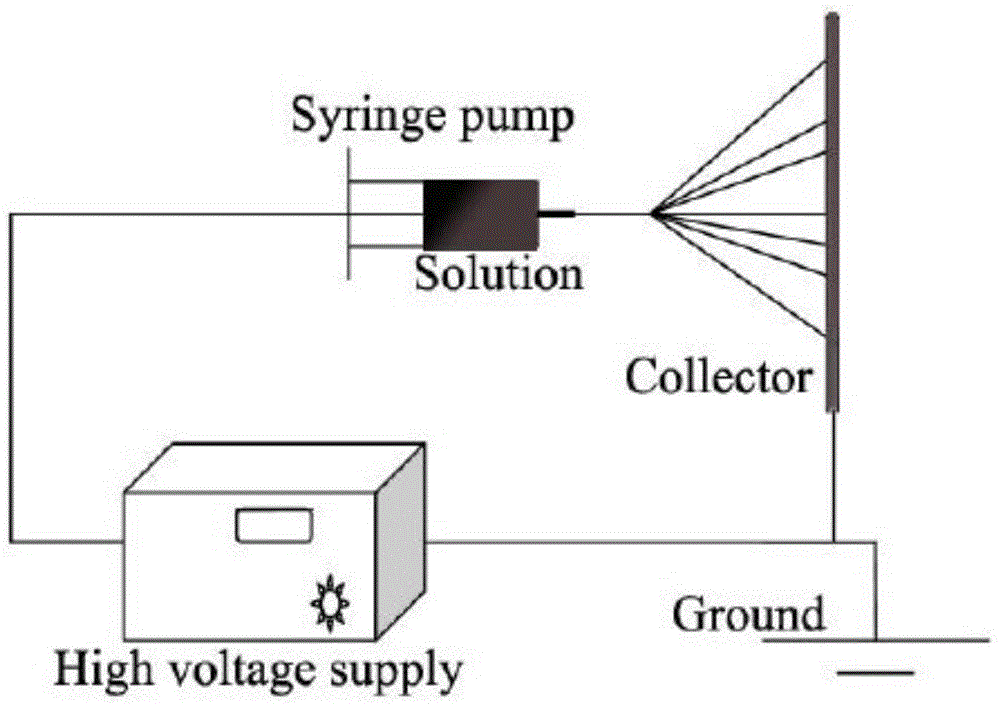

[0069]2) Dissolve polyacrylonitrile (PAN) in N,N-dimethylformamide (DMF), then use high-voltage electrospinning technology to weave PAN precursors, and put the spun PAN precursors in a tubular reactor Carry out carbonization to prepare carbon nanofibers (CNFs), then add carbon nanofibers (CNFs) in 1 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com