Anti-visible light and near-infrared detection fluorocarbon optical camouflage coating and preparation method thereof

A visible light and near-infrared technology, applied in the field of coatings, can solve the problems of poor aging resistance and short service life, and achieve the effects of super weather resistance, extended service life and high light resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

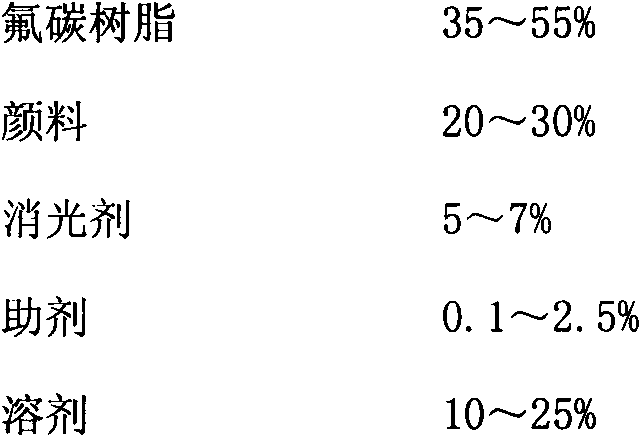

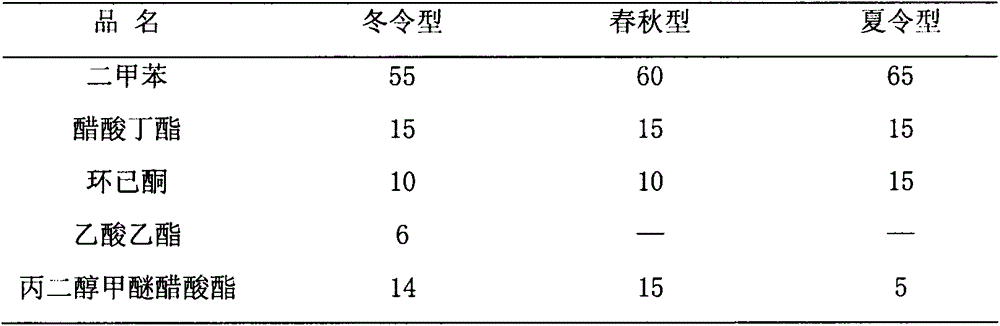

Method used

Image

Examples

Embodiment 1

[0039] Preparation of A component:

[0040] Weigh 330g of fluorocarbon resin, 20g of rutile TiO2 powder, 25g of medium chrome yellow powder, 4g of permanent red powder, 140g of green pigment powder, 80g of butyl acetate and 64g of xylene solvent, stir evenly, and then grind until the fineness is below 30μm. pulp, spare. Mix the remaining 130g of fluorocarbon resin, 60g of surface-treated silica, 1g of modified dimethylsiloxane, 10g of 2-hydroxy-4-n-octyloxybenzophenone, and 0.1g of dibutyltin dilaurate Evenly, under stirring, slowly add the ground color paste into the above-mentioned mixed material container, and stir well to obtain the finished product.

[0041] Preparation of component B:

[0042] Weigh 900g of N3390 curing agent, 2g of propylene glycol methyl ether acetate and 8g of butyl acetate solvent into the kettle, and stir evenly to obtain the finished product.

Embodiment 2

[0044] Preparation of A component:

[0045] Weigh 211g fluorocarbon resin, 23g rutile TiO 2 Powder, 35.8g strontium yellow and barium chrome yellow powder, 2.6g iron red powder, 195g green pigment powder, 100g propylene glycol methyl ether acetate and 113.5g ethyl acetate solvent, stir evenly, then grind to a fineness below 30μm to form a color paste, set aside . Mix the remaining 105g of fluorocarbon resin, 51g of surface-treated silica, 17g of 2-hydroxy-4-n-octyloxybenzophenone, and 0.1g of dibutyltin dilaurate. The slurry is slowly added into the container of the above-mentioned mixed materials, which is the finished product.

[0046] Preparation of component B:

[0047] Weigh 900g of N3390 curing agent, 2g of propylene glycol methyl ether acetate and 8g of butyl acetate solvent into the kettle, and stir evenly to obtain the finished product.

Embodiment 3

[0049] Preparation of A component:

[0050] Weigh 252g fluorocarbon resin, 23.5g rutile TiO 2 Powder, 27.8g barium chrome yellow powder, 4.3g scarlet and iron red powder, 159g green pigment powder, 50g propylene glycol methyl ether acetate, 50g ethyl acetate, 113.5g butyl acetate solvent, stir well, and then grind to fineness below 30μm Into the color paste, spare. The remaining 124g fluorocarbon resin, 49.5g surface-treated silica, 1.2g modified dimethylsiloxane solution, 0.5g 2-hydroxyl-4-n-octyloxybenzophenone, 0.01g dilaurel Dibutyltin dibutyltin is mixed evenly, and the ground color paste is slowly added into the container of the above-mentioned mixed materials under stirring, which is the paint for military vehicles.

[0051] Preparation of component B:

[0052] Weigh 900g of N3390 curing agent, 2g of propylene glycol methyl ether acetate and 8g of butyl acetate solvent into the kettle, and stir evenly to obtain the finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com