Preparation method of biogas residue organic fertilizer employing biochar as carrier

A technology of biogas residue organic fertilizer and biochar, which is applied in the treatment of bioorganic parts, waste fuel, etc., can solve the problems of difficult dehydration, solidification, mechanical dehydration and drying energy consumption of biogas residue, negative impact on soil, and unsuitable biogas residue fertilizer. , to slow down the greenhouse effect, reduce the cost of dehydration, and reduce emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

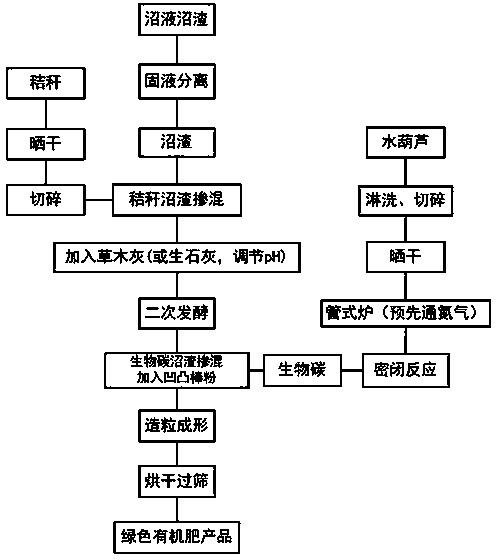

[0022] Such as figure 1 As shown, the moisture content of the biogas residue in the biogas digester is 87%, and it is pumped into the solid-liquid separator through the slurry pump, and the moisture content of the biogas residue after solid-liquid separation is 55%. The dried rice straw (moisture content is not more than 10%) is chopped, and the chopping degree is 6mm. Mix biogas residue and straw according to the ratio (weight ratio) of 3:1, add plant ash to adjust the pH to 7.1, stack the mixture in a greenhouse, lay a plastic film on the ground, and spread the mixture evenly on the plastic film. Buried a ventilation pipe, supplied air with a small blower, ventilated 3 times every 24 hours, with an interval of 8 hours between two ventilations, and each ventilation time was 3 minutes. Turn the pile once every 6 to 8 days, and obtain the biogas residue fermentation product after 40 days. The appearance of the biogas residue fermentation product is tea-brown and the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com