Chitosan quaternary ammonium salt containing triazole, and preparation method and application thereof

A technology of chitosan quaternary ammonium salt and triazole, which is applied in the field of marine chemical engineering, can solve the problems of expanding the use range of chitosan, poor water solubility, and affecting the use range of chitosan, and achieves antifungal activity and water solubility Improvement, biological activity improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

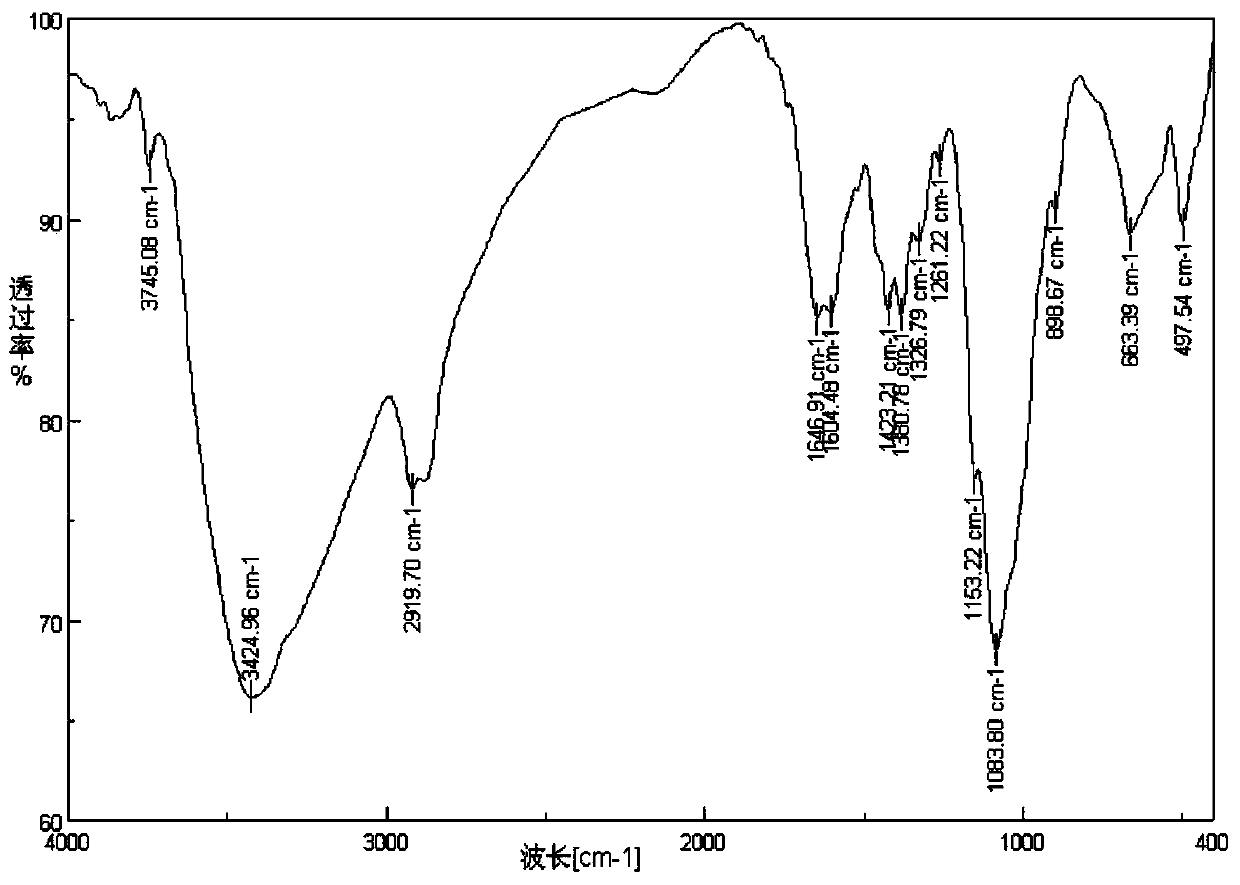

[0024] The triazole-containing chitosan quaternary ammonium salt is a compound represented by formula (1). At the same time, its preparation process is recorded as follows:

[0025]

[0026] The average value of n ranges from 20 to 3000; R is bromomethyl, phenyl or 1-hydroxyethyl.

[0027] In this example, the target compound a was synthesized according to the above synthetic route.

[0028] (1) Compounds 1-4 were synthesized by referring to the method in the literature (Ifuku, S., Wada, M., Morimoto, M., Saimoto, H. Preparation of highly regioselective chitosan derivatives via "click chemistry". Carbohydrate Polymers, 2011, 85, 653 –657).

[0029] (2) 0.72 g of the product (compound 4) obtained in step (1), 2.16 g of sodium iodide, 4 mL of sodium hydroxide solution (15%) and 4 mL of methyl iodide were added to 40 mL of N-methylpyrrolidone, and the temperature was raised to 60° C. Reaction for 1h. After the reaction, the reaction solution was poured into 100 mL of ethan...

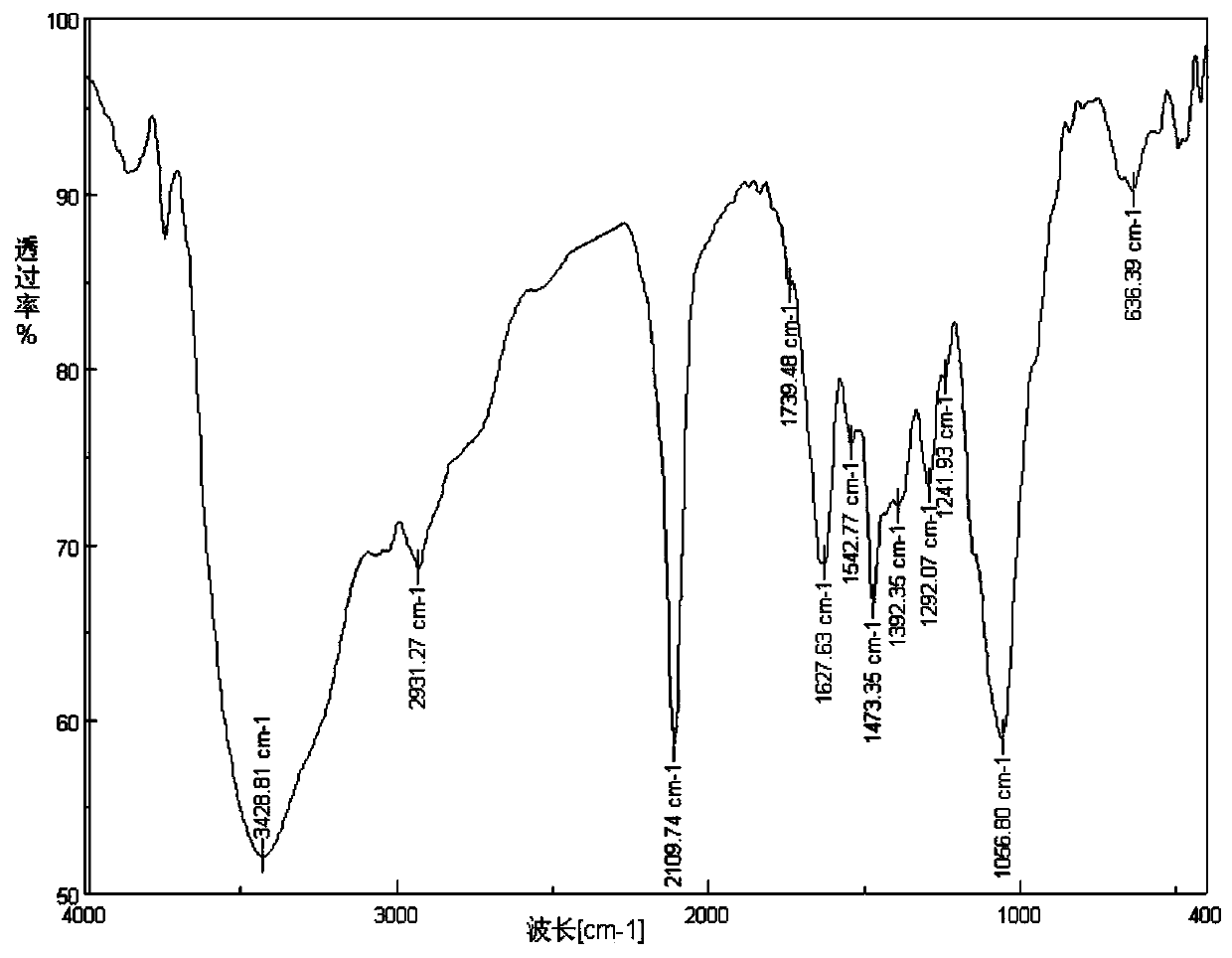

Embodiment 2

[0035] In this example, the target compound b was synthesized according to the above synthetic route. The difference from Example 1 is that:

[0036] (1) 0.72 g of compound 4, 5.58 g of sodium iodide, 10 mL of sodium hydroxide solution (15%) and 10 mL of methyl iodide were added to 40 mL of N-methylpyrrolidone, and the temperature was raised to 40° C. to react for 3 h. After the reaction, the reaction solution was poured into 100 mL of ethanol, and a precipitate was deposited. The precipitate was filtered with suction, washed with ethanol, and 1.1 g of the product (compound 5) dried at 60° C. was used for later use.

[0037] (2) 0.54 g of compound 5, 14 mg of cuprous iodide, 4.1 mL of triethylamine and 0.49 mL of phenylacetylene were added to 45 mL of dimethyl sulfoxide, and the temperature was raised to 90° C. to react for 48 h. After the reaction, the reaction solution was suction filtered, and the filtrate was poured into 50 mL of ethanol to precipitate a precipitate. Th...

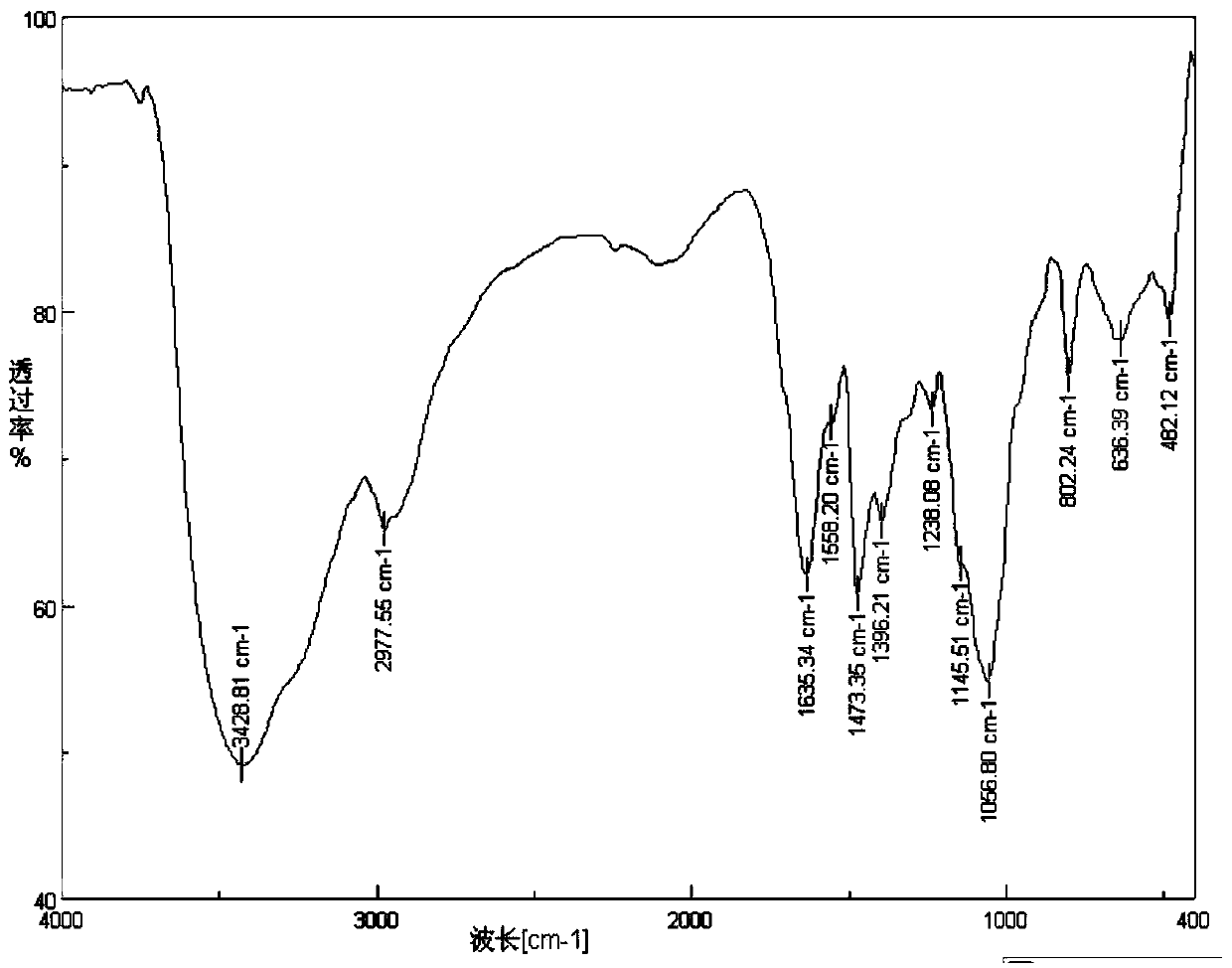

Embodiment 3

[0041] In this example, the target compound c was synthesized according to the above synthetic route. The difference from Example 1 is that:

[0042] (1) 0.72 g of compound 4, 0.74 g of sodium iodide, 1.4 mL of sodium hydroxide solution (15%) and 1.4 mL of methyl iodide were added to 40 mL of N-methylpyrrolidone, and the temperature was raised to 50° C. to react for 2 h. After the reaction, the reaction solution was poured into 100 mL of ethanol, and a precipitate was deposited. The precipitate was filtered with suction, washed with ethanol, and 1.1 g of the product (compound 5) dried at 60° C. was used for later use.

[0043] (2) 0.54 g of compound 5, 7 mg of cuprous iodide, 3.1 mL of triethylamine and 0.23 mL of 3-butyn-1-ol were added to 50 mL of dimethyl sulfoxide, and the temperature was raised to 80° C. to react for 60 h. After the reaction, the reaction solution was suction filtered, and the filtrate was poured into 50 mL of ethanol to precipitate a precipitate. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com