Preparation method for an Ag/AgBr/GO nano-composite photocatalyst

A photocatalyst and nanocomposite technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve cumbersome problems, achieve high catalytic efficiency, good catalytic stability, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

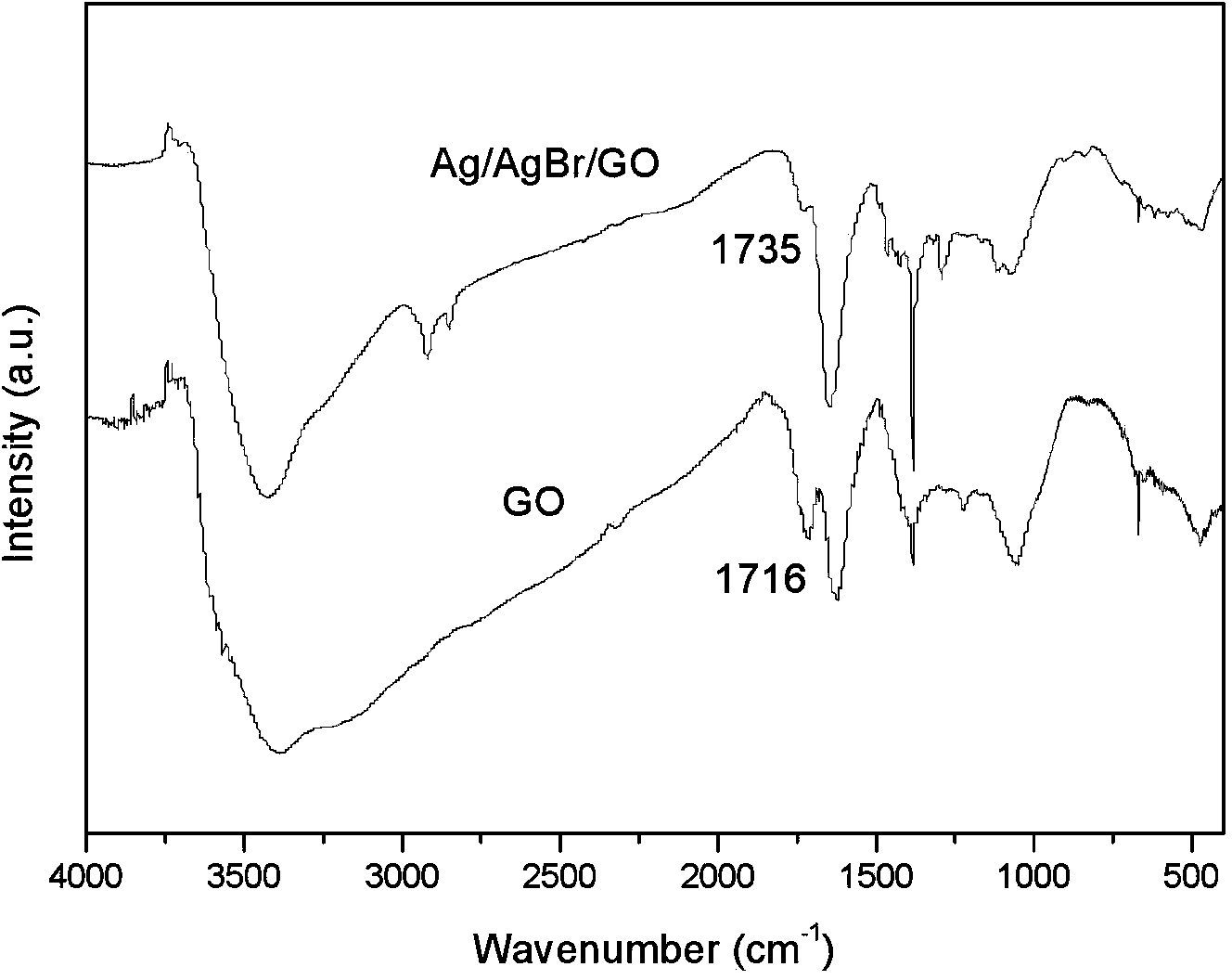

Method used

Image

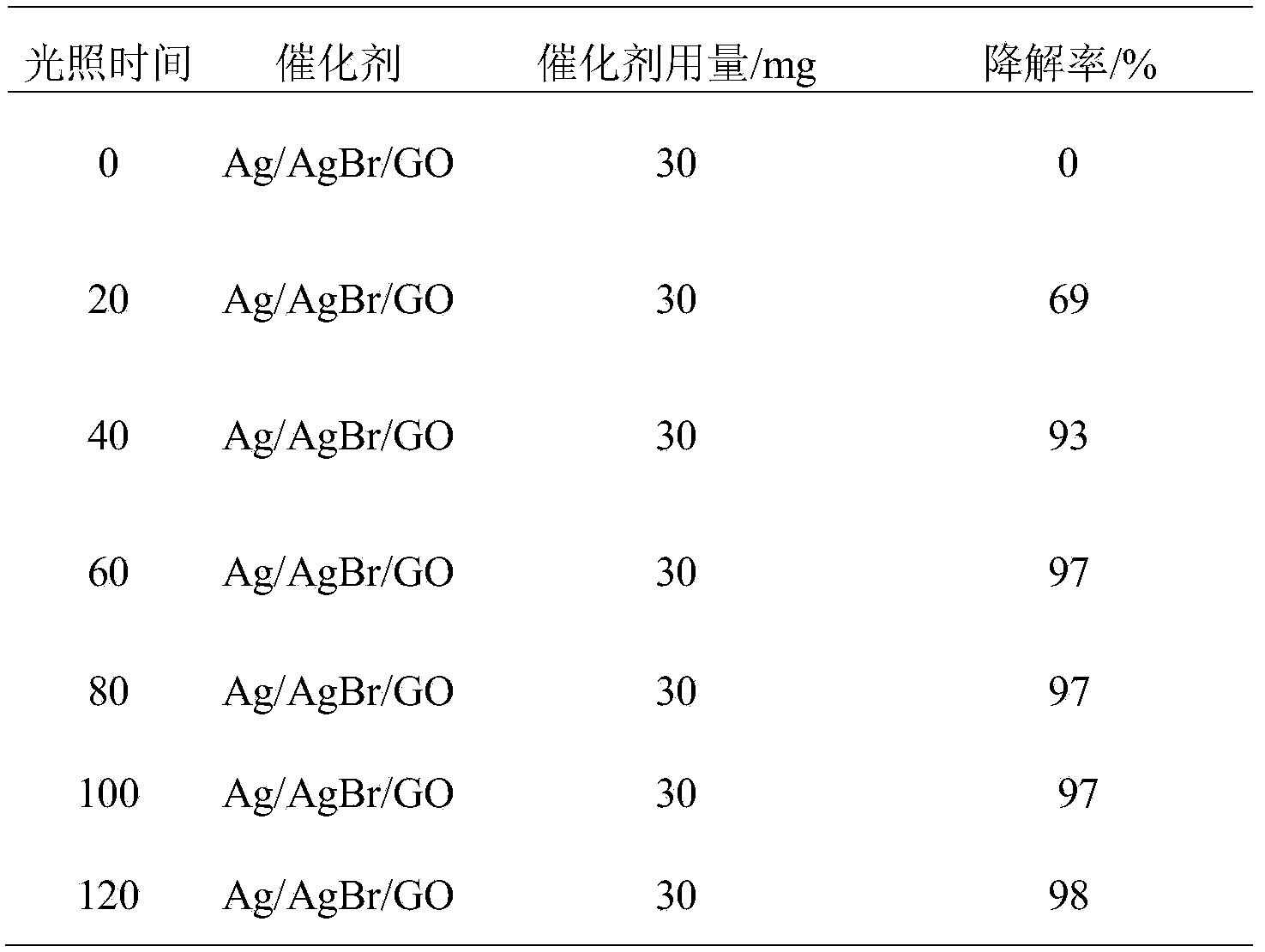

Examples

Embodiment 1

[0027] The specific preparation steps of 1#Ag / AgBr / GO nanocomposite are as follows:

[0028] (1) Preparation of GO

[0029] 0.5g graphite powder and 1.5g KMnO 4 Put it into a round-bottomed flask containing 12 mL of concentrated sulfuric acid, stir magnetically for 4 h under ice-water bath conditions, heat to 35 °C, stir at constant temperature for 30 min, add 23 mL of distilled water dropwise, heat up to 98 °C, stir for 15 min, and transfer the mixture to ice In the water bath, add 70 mL of distilled water to dilute, then add 10 mL of 30% hydrogen peroxide, stir for 30 min, the solution turns yellow, centrifuge, fully wash until the pH of the supernatant is 7, and dry the lower sediment to obtain GO.

[0030] (2) Preparation of Ag / AgBr / GO nanocomposites

[0031] Measure 12 mL of ethylene glycol and put it into a round-bottomed flask, stir at a constant temperature of 60 °C for 30 min, add 54 mg of PVP and 120 mg of CTAB, continue to stir until the two are completely dissolv...

Embodiment 2

[0033] The specific preparation steps of 2#Ag / AgBr / GO nanocomposites are as follows:

[0034] (1) Preparation of GO

[0035] The same as the preparation method of GO in Example 1.

[0036] (2) Preparation of Ag / AgBr / GO nanocomposites

[0037] Measure 12 mL of ethylene glycol and put it into a round-bottomed flask, stir at a constant temperature of 60 °C for 30 min, add 95 mg of PVP and 120 mg of CTAB, continue to stir until the two are completely dissolved, then add 5 mg of GO prepared by the above method, and continue to stir for 2 h to make GO is uniformly distributed in the above solution, and the suspension at this time is called A. In addition, weigh 100mg AgNO at room temperature 3 , which was dissolved in 1.5 mL of ethylene glycol, called solution B. Under stirring, drop solution B into suspension A with a plastic dropper, stir for 30 min, increase the temperature to 155°C, and stir for 15 min to complete the reaction. The reactants were cooled to room temperature,...

Embodiment 3

[0039] The specific preparation steps of 3#Ag / AgBr / GO nanocomposites are as follows:

[0040] (1) Preparation of GO

[0041] The same as the preparation method of GO in Example 1.

[0042] (2) Preparation of Ag / AgBr / GO nanocomposites

[0043] Measure 12 mL of ethylene glycol and put it into a round-bottomed flask, stir at a constant temperature of 60 °C for 30 min, add 150 mg of PVP and 120 mg of CTAB, continue to stir until the two are completely dissolved, then add 5 mg of GO prepared by the above method, and continue to stir for 2 h to make GO is uniformly distributed in the above solution, and the suspension at this time is called A. In addition, weigh 100mg AgNO at room temperature 3 , which was dissolved in 1.5 mL of ethylene glycol, called solution B. Under stirring, drop solution B into suspension A with a plastic dropper, stir for 30 min, increase the temperature to 155°C, and stir for 15 min to complete the reaction. The reactants were cooled to room temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com