Tubular metallic membrane reactor and application thereof

A membrane reactor and reactor technology, applied in non-metallic elements, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of increasing the reaction space velocity conversion rate, etc., and achieve improved conversion rate and thermal efficiency, excellent sealing structure, The effect of high hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

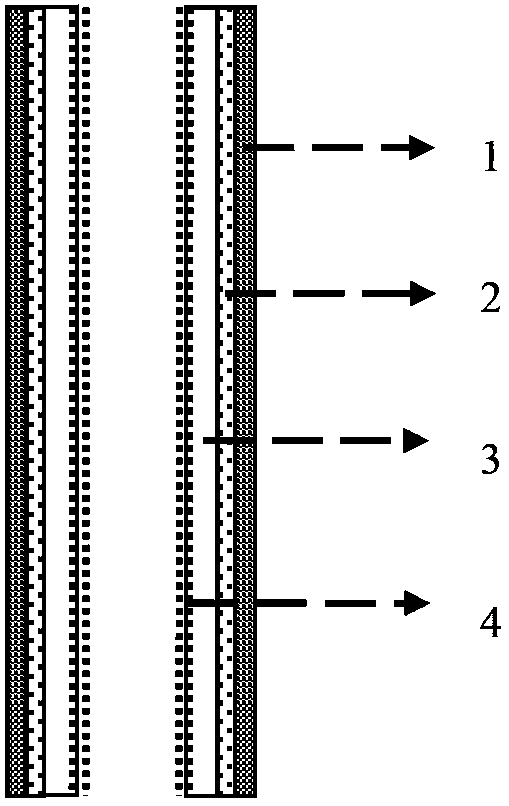

[0032] Preparation of Li by impregnation method 2 O-La 2 o 3 -Ni / α-Al 2 o 3 catalyst. With Li 2 O and La 2 o 3 Ni-based catalysts as promoters were prepared by impregnation. First the tubular α-Al 2 o 3 The inner surface of the porous bottom membrane was impregnated with LiNO 3 , La(NO 3 ) 3 and Ni(NO 3 ) 2 In the mixed solution, it is first dried at 110°C, and then roasted at a high temperature of 600-750°C. Repeat the above heat treatment steps to obtain the inner surface loaded Li 2 O-La 2 o 3 -Ni / α-Al 2 o 3 active catalyst substrates, such as figure 1 shown.

Embodiment 2

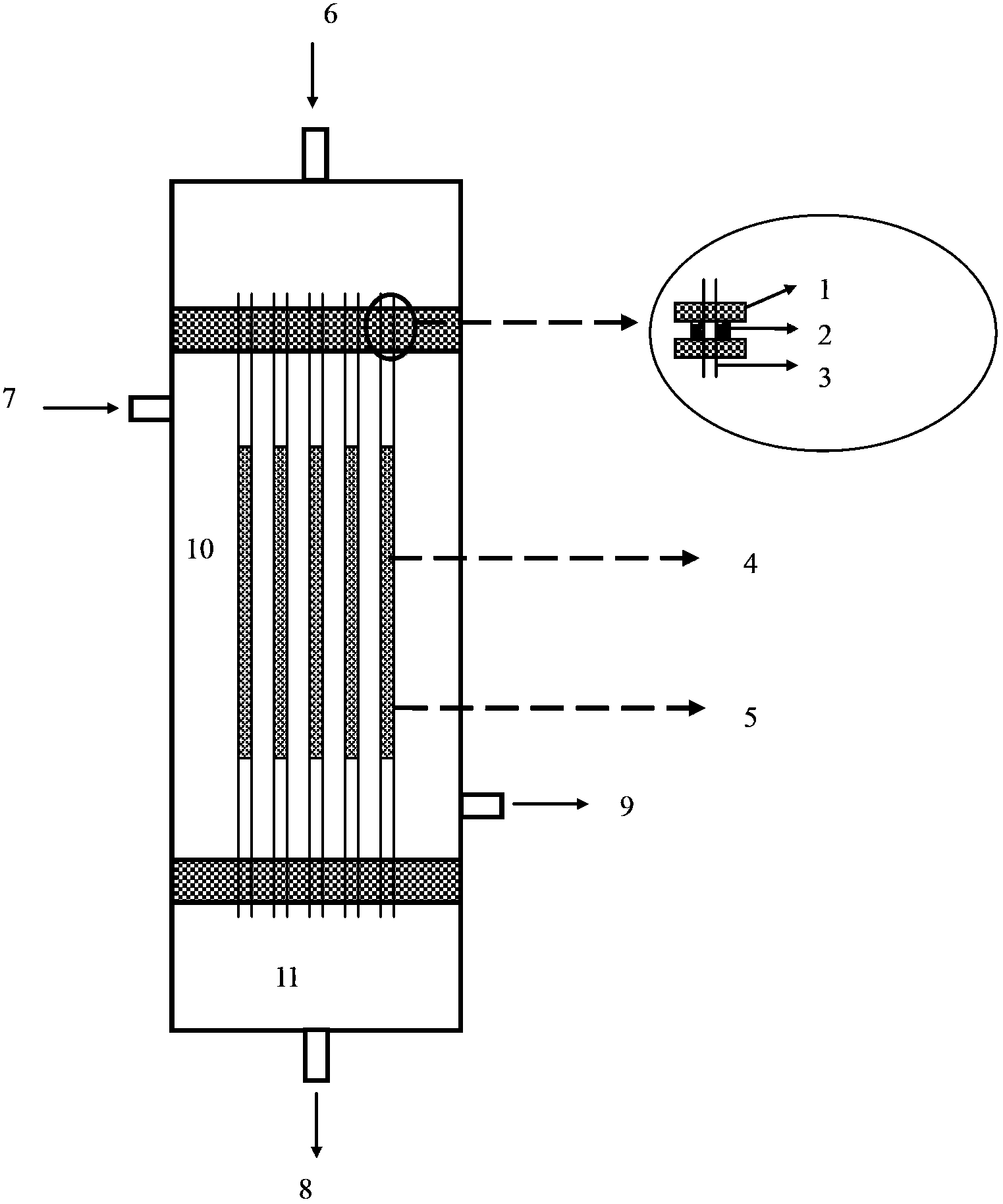

[0034] Modification of a layer of γ-Al on the outer surface of porous alumina ceramic bottom film by vacuum sol modification method 2 o 3 , dried naturally for two days, then put into a muffle furnace and heat up to 600 ° C for 1-5 hours to bake for 1-5 hours to obtain a modified porous base film with a thickness of about 5-100 μm and an average pore diameter of about 2-50 nm. The optimized sensitization and activation method was used to introduce palladium seeds on the porous bottom membrane. Then put the bottom film into 0.025mol / L Pd metal salt complex and 1mol / L N 2 h 4 ·H 2 The palladium film was plated in the electroless plating solution composed of O, and the thickness of the palladium composite film was about 5 μm, and it was uniform and dense.

Embodiment 3

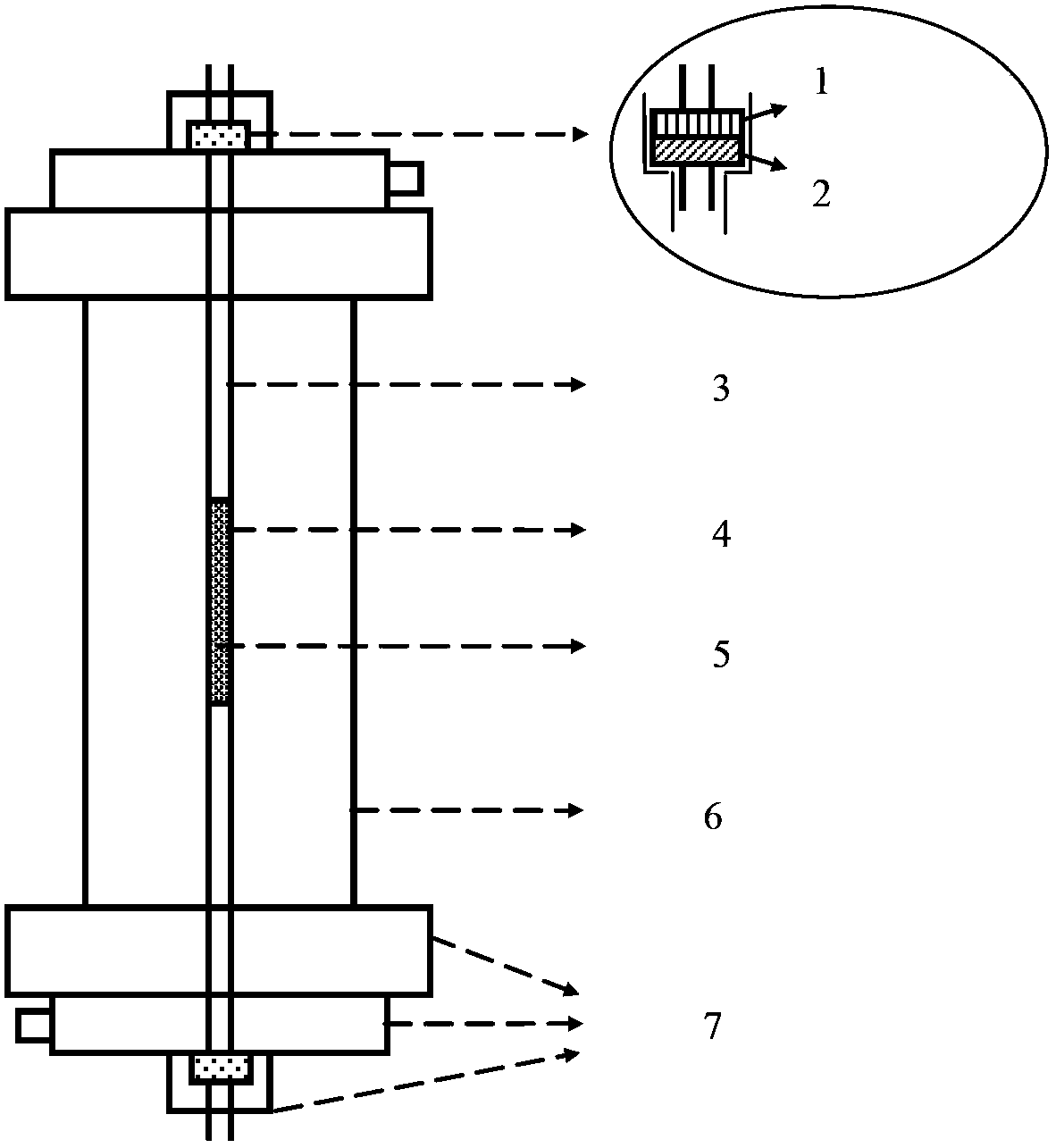

[0036] O-shaped rubber ring is used as the sealing material of the palladium membrane reactor, such as figure 2 As shown, the palladium composite film is located inside the stainless steel tube. The palladium composite film is fixed by stainless steel ferrules at both ends of the stainless steel tube, and then the inner connection of the ferrule is sealed with an O-shaped rubber ring. The membrane reactor is placed in a tubular electric furnace, and the stainless steel ferrules at both ends are placed outside the electric furnace, that is, the reactor can be sealed with an O-shaped rubber ring at low temperature and the sealing effect is excellent. Seal the opening of the stainless steel ferrule at the upper end of the membrane reactor, feed the reaction gas from the upper opening of the palladium composite membrane, and vacuum the opening of the stainless steel ferrule at the lower end of the membrane reactor, and the area between the palladium composite membrane and the stai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com