A kind of aminoglycerin refining device and its purification process

An aminoglycerin and process technology, which is applied in the field of aminoglycerin refining process and equipment, can solve the problems of large amount of impurities, low product purity, high impurity content, etc., and achieve the effects of low gas phase temperature, short distillation time and low liquid phase temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1, the processed unqualified product, the content of aminoglycerin is 95.23% (GC), and the appearance is pale yellow.

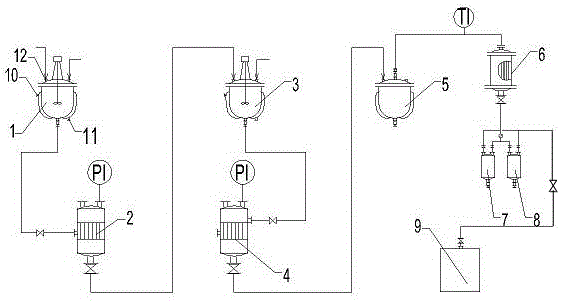

[0025] Such as figure 1 As shown, a refining device for aminoglycerol includes a crystallization kettle 1, a first precision filter 2, a decolorization kettle 3, a second precision filter 4, a finished product distillation kettle 5, a condenser 6, a front The distillate tank 7, the finished product tank 8 and the Roots vacuum unit 9; the crystallization kettle 1 is provided with a cold brine outlet 10, a cold brine inlet 11 and an unqualified aminoglycerin inlet 12.

[0026] The purification process of above-mentioned aminoglycerin comprises the following steps:

[0027] A. Put 100Kg of aminoglycerin into the crystallization kettle 1 through the unqualified aminoglycerin inlet 12, and feed in the frozen brine with a temperature of -5--10°C through the cold brine inlet 11, and put the pressure into the crystallization kettle 1 after 60 minut...

Embodiment 2

[0034] Embodiment 2, the unqualified product of processing, aminoglycerin content 96.69% (GC), outward appearance is tan.

[0035] Such as figure 1 As shown, a refining device for aminoglycerol includes a crystallization kettle 1, a first precision filter 2, a decolorization kettle 3, a second precision filter 4, a finished product distillation kettle 5, a condenser 6, a front The distillate tank 7, the finished product tank 8 and the Roots vacuum unit; the crystallization kettle 1 is provided with a cold brine outlet 10, a cold brine inlet 11 and an unqualified aminoglycerin inlet 12.

[0036] The purification process of above-mentioned aminoglycerin comprises the following steps:

[0037] A. Put 80Kg of aminoglycerin into the crystallization kettle 1 through the unqualified aminoglycerin inlet 12, and feed in the frozen brine with a temperature of -5--10°C through the cold brine inlet 11, and put the pressure into the crystallization kettle 1 after 70 minutes. The compress...

Embodiment 3

[0044] Embodiment 3, the processed unqualified product, the content of aminoglycerol is 94.33% (GC), and the appearance is brownish yellow.

[0045] Such as figure 1 As shown, a refining device for aminoglycerol includes a crystallization kettle 1, a first precision filter 2, a decolorization kettle 3, a second precision filter 4, a finished product distillation kettle 5, a condenser 6, a front The distillate tank 7, the finished product tank 8 and the Roots vacuum unit; the crystallization kettle 1 is provided with a cold brine outlet 10, a cold brine inlet 11 and an unqualified aminoglycerin inlet 12.

[0046] The purification process of above-mentioned aminoglycerin comprises the following steps:

[0047]A. Put 120Kg of aminoglycerin into the crystallization kettle 1 through the unqualified aminoglycerin inlet 12, and feed the frozen brine with a temperature of -5--10°C through the cold brine inlet 11, and put the pressure into the crystallization kettle 1 after 80 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com