Novel method for determination of total iron of iron ore by potassium dichromate volumetric method

A potassium dichromate, volumetric method, applied in chemical analysis by titration, material analysis by observing the effect on chemical indicators, and analysis by chemical reaction of materials, etc. Problems such as poor control of test operating conditions to achieve the effect of pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to describe the present invention, below in conjunction with accompanying drawing and embodiment the new method of the present invention a kind of potassium dichromate volumetric determination total iron in iron ore is described in further detail.

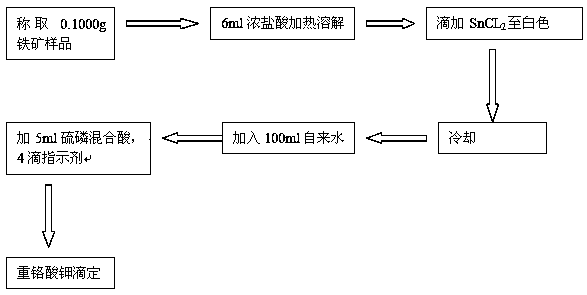

[0025] Depend on figure 1 The operation process block diagram of the new method for the determination of total iron in iron ore by a kind of potassium dichromate volumetric method of the present invention shown, the concrete operation process of the inventive method is: the iron ore sample is pulverized to particle size<0.088 millimeter; Take 0.1000g of crushed and ground iron ore sample, put it into a 250ml Erlenmeyer flask, add a small amount of water to moisten it, add 6ml of concentrated hydrochloric acid, cover it, and dissolve it on a hot plate. Add dropwise tin dichloride solution with a mass concentration of 6% until it turns white. After water cooling or natural cooling, quickly add 100 ml of tap water, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com