Double-nested copper interconnection structure and fabrication method thereof

A technology of copper interconnection structure and manufacturing method, which is applied in semiconductor/solid-state device manufacturing, electrical components, electric solid-state devices, etc., can solve the problems of device open-circuit contact resistance, diffusion barrier copper easily diffused into the medium, and device short-circuit, etc. Achieve the effects of avoiding short circuit of the device, improving reliability and anti-electromigration ability, and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

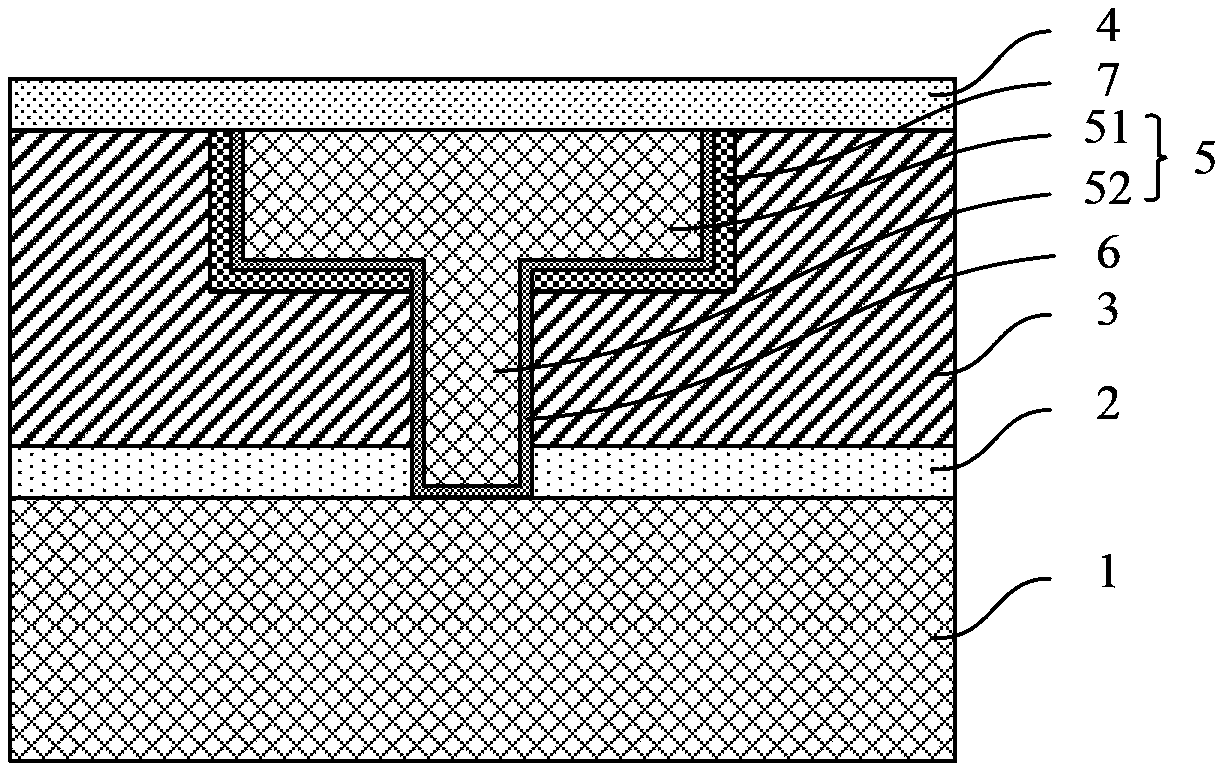

[0057] The present invention provides a dual-nested copper interconnect structure, see figure 1, which is a schematic cross-sectional structure diagram of the dual nested copper interconnection structure of the present invention. As shown in the figure, the dual nested copper interconnection structure at least includes: a first copper layer 1, which is sequentially formed on the first copper layer The first cap layer 2, the interlayer dielectric layer 3 and the second cap layer 4; the second copper layer 5 for conductive interconnection is formed in the interlayer dielectric layer 3 and the first cap layer 2, and the The upper surface of the second copper layer 5 is connected to the lower surface of the second cap layer 4, and the remaining part of the second copper layer 5 except the upper surface is surrounded by a metal diffusion barrier layer 6, and the metal diffusion barrier layer 6, the bottom is connected to the upper surface of the first copper layer 1; the second cop...

Embodiment 2

[0077] Embodiment 2 adopts basically the same technical solution as Embodiment 1, except that the structure of the nitrogen-doped layer in the double-nested copper interconnection structure is different. In the double-nested copper interconnection structure of the first embodiment, only the nitrogen-doped layer is around the metal wiring, while in the double-nested copper interconnection structure of the second embodiment, there are nitrogen-doped layers around the metal wiring and the conductive plug, further Improve the adhesion between metal and medium and metal diffusion barrier ability.

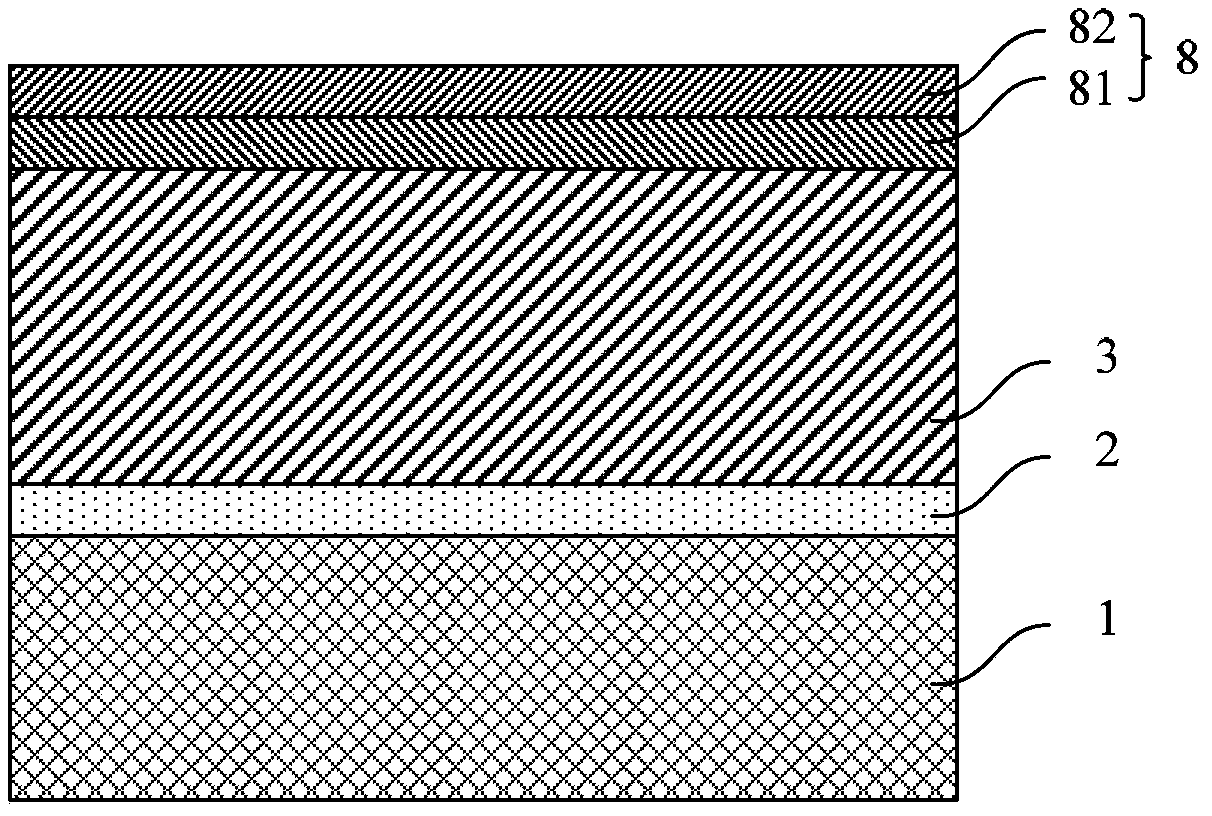

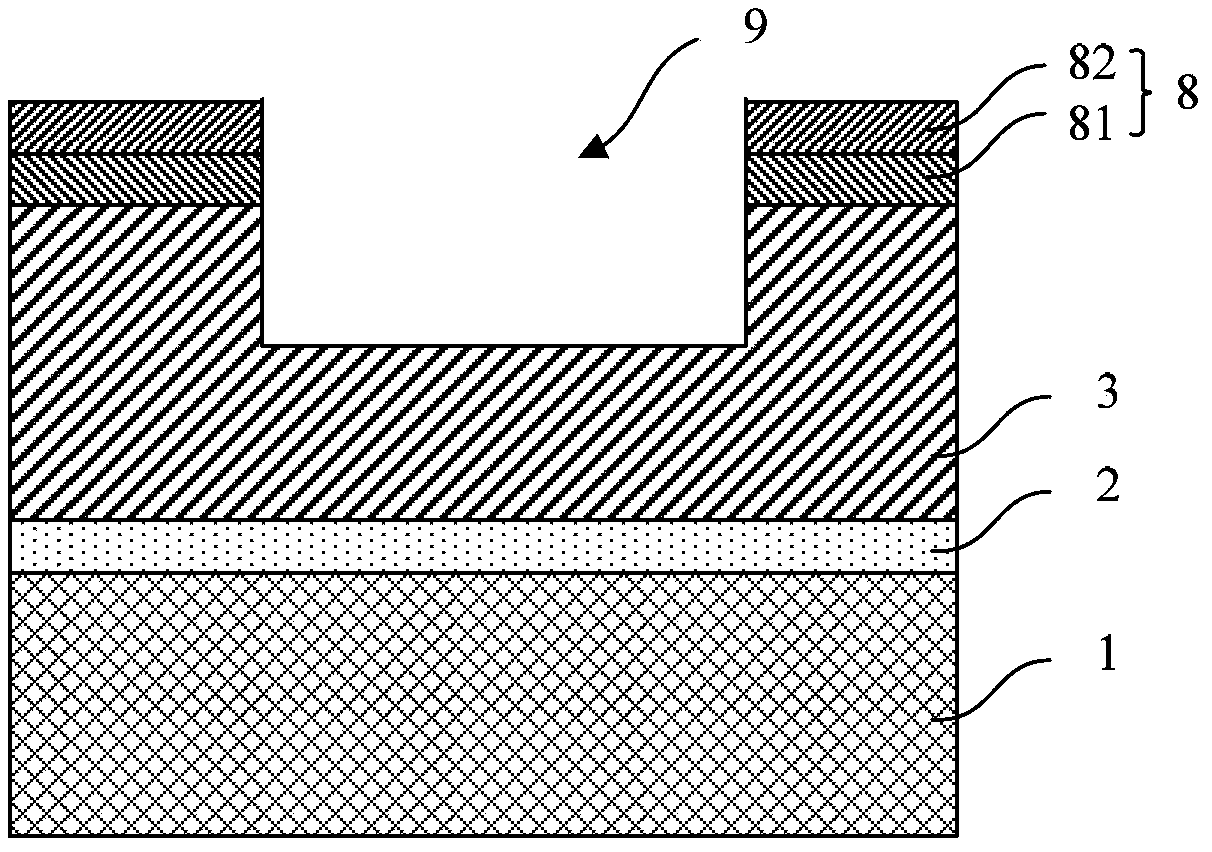

[0078] The present invention provides a dual-nested copper interconnect structure, see Figure 10 , which is a schematic cross-sectional structure diagram of the dual nested copper interconnection structure of the present invention. As shown in the figure, the dual nested copper interconnection structure at least includes: a first copper layer 1, which is sequentially formed on the first...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com