Ultrasound spray pyrolysis preparation method of MgO buffer layer for coating conductor

A technology of ultrasonic spray pyrolysis and coated conductors, which is applied in the usage of superconductor elements, cable/conductor manufacturing, coating, etc. It can solve the problems of unfavorable large-scale industrial production and the need for vacuum systems, etc., and achieves fast film formation, The effect of simplifying equipment and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

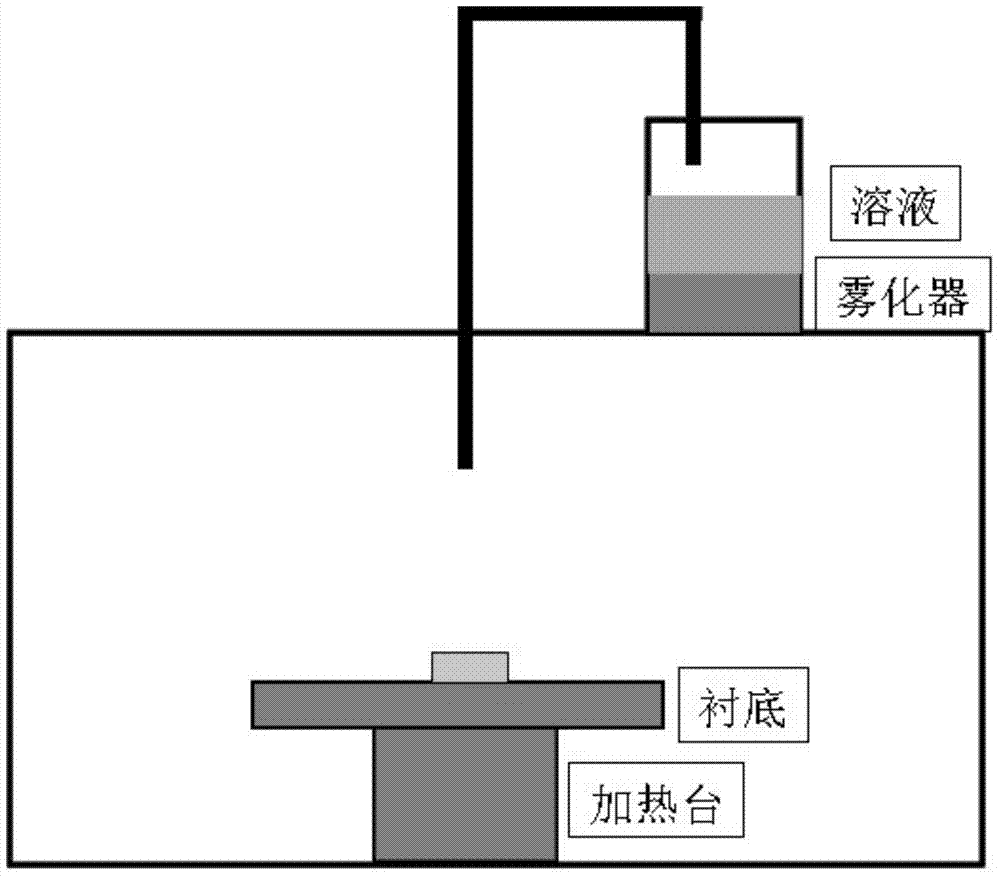

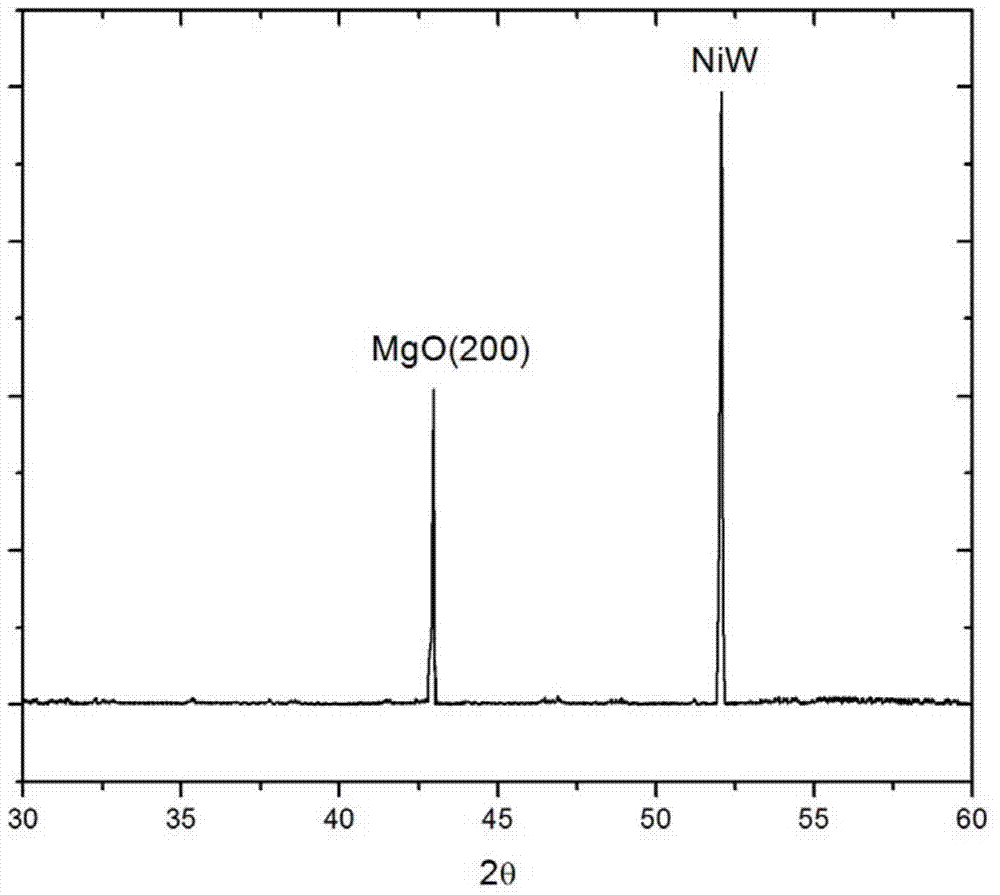

[0020] The object of the present invention is to provide a method for preparing a magnesium oxide buffer layer for coated conductors by ultrasonic spray pyrolysis, which does not require vacuum equipment and is suitable for large-scale industrial production. Using the method of ultrasonic spray pyrolysis, magnesium nitrate solution is used as the precursor solution, and the magnesium oxide buffer layer is epitaxially grown on the NiW alloy substrate through the technology of ultrasonic atomization pyrolysis. The schematic diagram of its preparation device is shown in figure 1 As shown in the figure, the substrate is fixed on the heating platform, and the precursor liquid uses the ultrasonic atomizer to generate mist droplets, and reaches the top of the substrate along the quartz tube, and deposits a film on the substrate after thermal decomposition. Main steps of the present invention are as follows:

[0021] Step 1: cleaning the metal NiW alloy substrate with a high cubic te...

Embodiment 1

[0031] This example is prepared by ultrasonic spray pyrolysis of magnesium oxide buffer layer for coated conductor. The specific process is as follows:

[0032] Step 1, using 99.99% acetone, alcohol and deionized water in order to ultrasonically clean the YBCO superconducting layer of the high-temperature superconducting coating conductor;

[0033] Step 2, suspend and immerse in the diluted nitric acid solution with a concentration of 30%-50% for 40-120s to remove surface oxidation, take it out, wash and dry;

[0034] Step 3 Fix the cleaned cubic-textured metal NiW alloy substrate on a heating table, the distance from the nozzle to the substrate is 4 cm, and then heat to 580° C.

[0035] Step 4: Use 0.3mol / L magnesium nitrate solution as the precursor solution, use an ultrasonic atomizer to atomize and spray the precursor solution on the NiW alloy substrate, spray for 20 seconds, stop for 40 seconds and repeat the spraying method, lasts 10 minutes in total;

[0036] Step 5,...

Embodiment 2

[0038] This example is prepared by ultrasonic spray pyrolysis of magnesium oxide buffer layer for coated conductor. The specific process is as follows:

[0039] Step 1, using 99.99% acetone, alcohol and deionized water in order to ultrasonically clean the YBCO superconducting layer of the high-temperature superconducting coating conductor;

[0040] Step 2, suspend and immerse in the diluted nitric acid solution with a concentration of 30%-50% for 40-120s to remove surface oxidation, take it out, wash and dry;

[0041] Step 3 Fix the cleaned cubic-textured metal NiW alloy substrate on a heating table, the distance from the nozzle to the substrate is 5 cm, and then heat to 590° C.

[0042] Step 4 Use 0.5mol / L magnesium nitrate solution as the precursor liquid, and use an ultrasonic atomizer to atomize and spray the precursor liquid on the NiW alloy substrate. The atomization spraying method is sprayed for 30 seconds, stopped for 60 seconds, and then repeated spraying. lasts fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com