Method for removing scaling of surface of titanium anode for electrolytic copper foil

A technology for electrolytic copper foil and titanium anode, applied in electrolytic process, electrolytic components, electroforming and other directions, can solve the problems of corrosion of titanium substrate and precious metal coating, waste of scaling removal efficiency, harsh operating environment, etc. The effect of mild and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Put the scale-covered titanium anode plate in a mixed solution of 25% sodium chloride and 5% calcium chloride by mass fraction, soak it at 80°C for 2.0h, take it out and scrub it with a brush or plastic brush until the scale cannot be removed. Then place the anode plate in Na with a mass concentration of 10% 2 SO 3 After soaking in the solution for 1 hour at 60°C, take it out and scrub it with a brush or plastic brush. Finally, place the anode plate in a mixed solution of triammonium citrate with a mass concentration of 10% and fatty alcohol polyoxyethylene ether with a mass concentration of 0.5%, soak it at 70°C for 1 hour, take it out and scrub it with a brush or plastic brush At this time, the scaling is basically completely removed.

Embodiment 2

[0038] Put the scale-covered titanium anode plate in a mixed solution of 28% sodium chloride and 4% calcium chloride by mass fraction, soak it at 70°C for 2.5 hours, take it out and scrub it with a brush or plastic brush until the scale cannot be removed. Then place the anode plate in 10% Na 2 In S solution, soak at 70°C for 1 hour, take it out and scrub it with a hair brush or plastic brush. Finally, put the anode plate in a mixed solution of 8% sodium citrate and 0.8% fatty alcohol polyoxyethylene ether, soak it at 80°C for 1 hour, take it out and scrub it with a brush or plastic brush, and the scaling is basically complete at this time Remove cleanly.

Embodiment 3

[0040] Put the scale-covered titanium anode plate in a mixed solution of 24% sodium chloride and 6% calcium chloride by mass fraction, soak it at 90°C for 1.5h, take it out and scrub it with a brush or plastic brush until the scale cannot be removed. Then place the anode plate in 8% Na 2 SO 3 with Na 2 In the composition solution of S, soak it at 50°C for 1.5h, take it out and scrub it with a hair brush or plastic brush. Finally, place the anode plate in a mixed solution of 12% sodium citrate and 0.3% fatty alcohol polyoxyethylene ether, soak it at 60°C for 1.5 hours, take it out and scrub it with a hair brush or plastic brush. Removes completely.

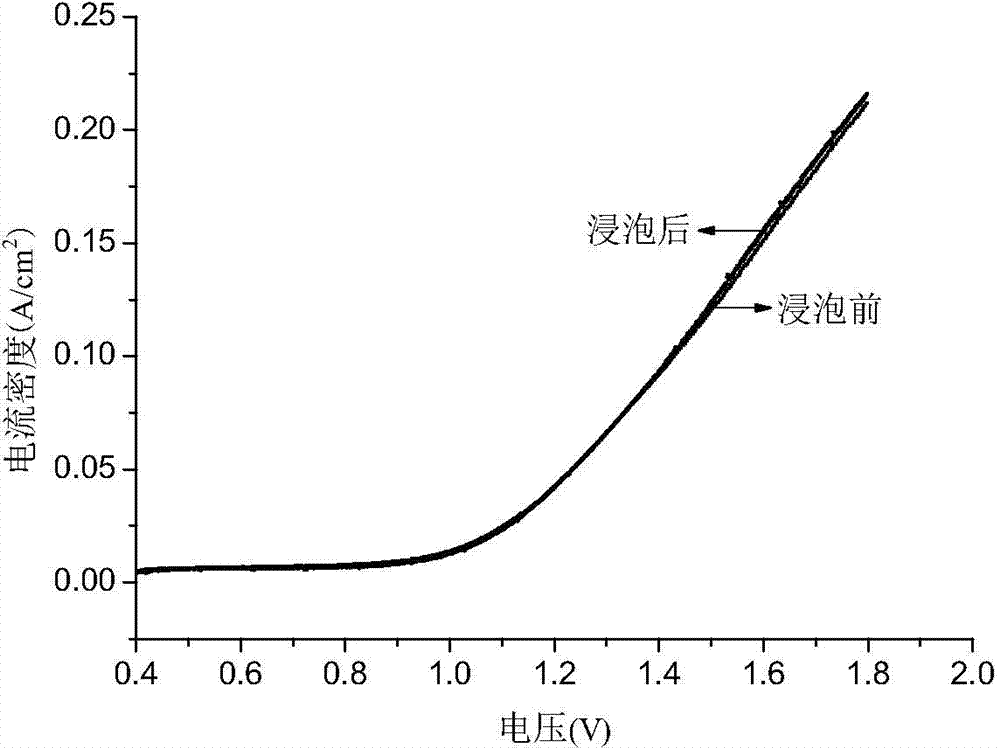

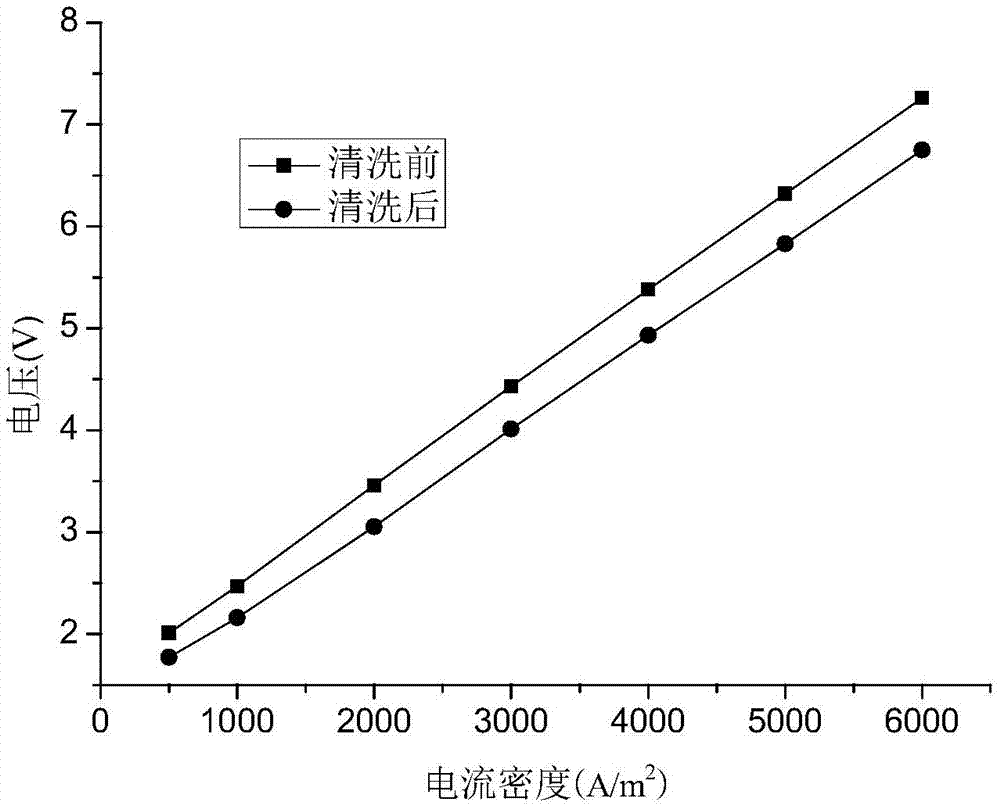

[0041] figure 1 It is the oxygen evolution polarization curve of the unused anode before and after soaking in the three-step solution, which is used to compare the influence of the cleaning solution on the electrochemical activity of the coating. figure 2 It is the relationship curve of the change of cell voltage at differen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com