Composite electrode plate of lithium ion battery, preparation method of composite electrode plate and lithium ion battery

A lithium-ion battery and composite electrode technology, which is applied to battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve the problems of unstable attachment of inorganic ceramic diaphragm layers, material dropping, and easy cracks in the diaphragm layer. To achieve the effects of improving safety performance and cycle life, overcoming unstable material, high safety performance and cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

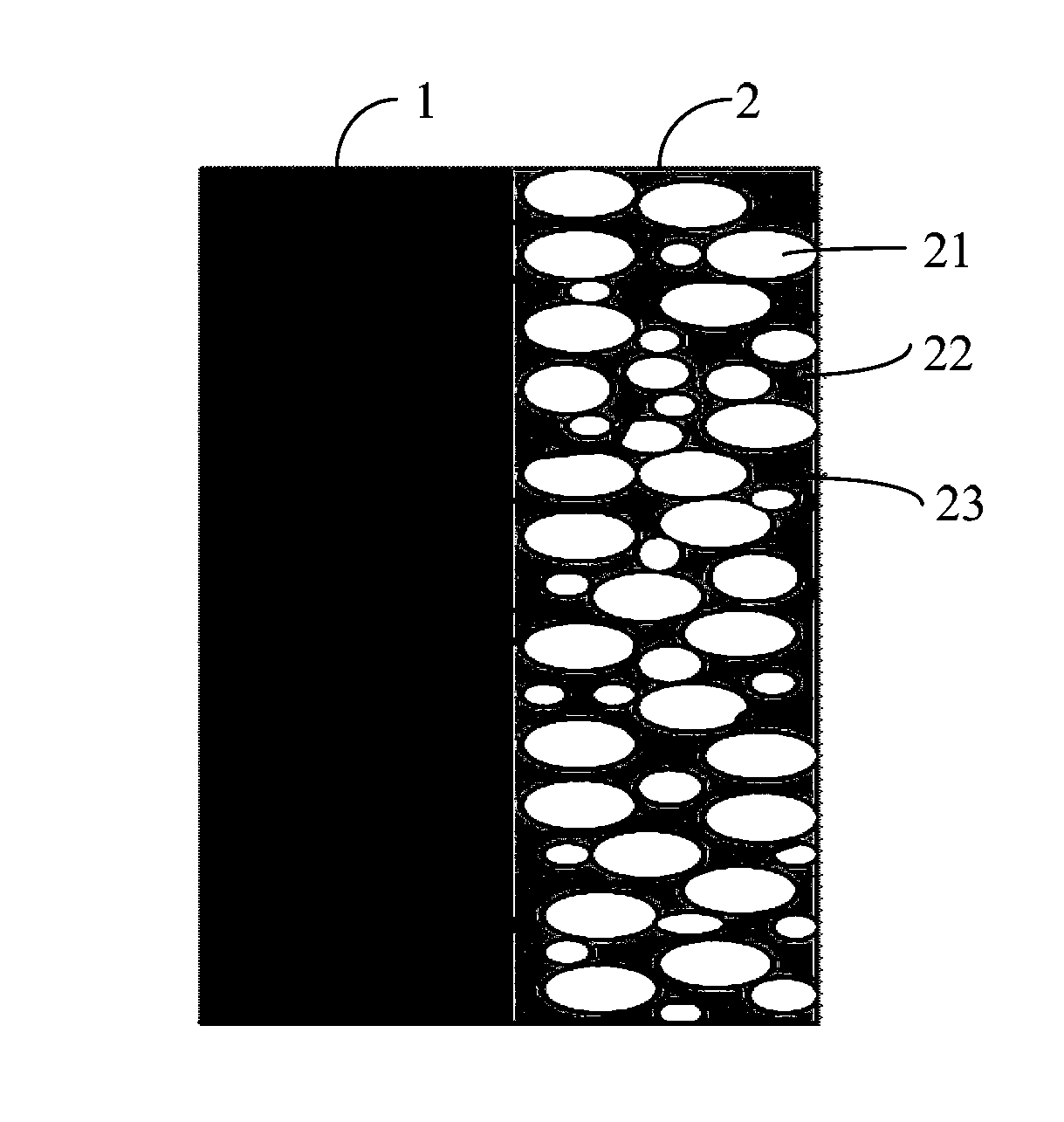

[0048] In the second aspect, the embodiment of the present invention provides a method for preparing a lithium-ion battery composite electrode sheet, comprising the following steps: dispersing inorganic ceramic particles and a binder in an organic solvent, after grinding, adding organic fibers, and stirring to form Mixture, the melting point of the organic fiber is greater than 200°C, the diameter of the organic fiber is 0.1 μm to 10 μm, the length is 1 mm to 10 mm, and the mass of the organic fiber is 0.1% to 2% of the mass of the inorganic ceramic particles ;

[0049] Take an electrode sheet, the electrode sheet is composed of a current collector and an electrode active material coated on the surface of the current collector, uniformly coat the mixture obtained above on the electrode sheet, and dry at 60-100°C for 60 minutes to obtain a lithium-ion battery Composite electrodes.

[0050] The organic fiber is one or more of polyester fiber, polyamide fiber, polyvinyl alcohol ...

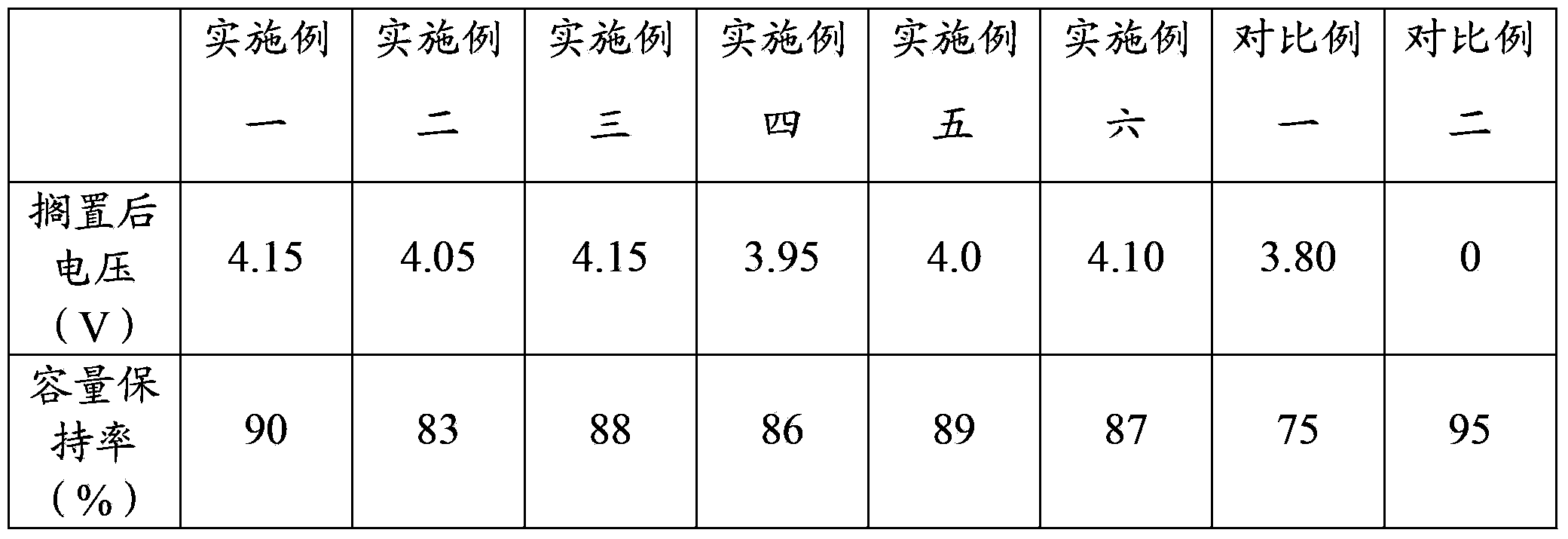

Embodiment 1

[0072]A preparation method for a composite negative electrode sheet for a lithium ion battery, comprising the steps of:

[0073] (1) Negative electrode sheet preparation

[0074] The mixture of 200 grams of negative electrode active material artificial graphite, 3 grams of binder styrene-butadiene rubber (SBR) and 3 grams of carboxymethyl cellulose (CMC) is added to 200 grams of water, then stirred in a vacuum mixer to form a uniform slurry . The slurry was uniformly coated on a 9-micron copper foil, then dried at 100° C., and rolled to obtain a negative electrode sheet with a thickness of 120 microns.

[0075] (2) Preparation of composite negative electrode sheets for lithium-ion batteries

[0076] Al with a particle size of 500nm 2 o 3 Powder and binder polyvinylidene fluoride-cohexafluoropropylene (PVDF-HFP) dispersed in acetone solvent, in which, Al 2 o 3 The mass ratio of powder and PVDF-HFP is 95:5. After grinding for 30 minutes, add polyacrylonitrile fibers with a...

Embodiment 2

[0083] A preparation method for a composite negative electrode sheet for a lithium ion battery, comprising the steps of:

[0084] (1) Negative electrode sheet preparation

[0085] The mixture of 200 grams of negative electrode active material artificial graphite, 3 grams of binder styrene-butadiene rubber (SBR) and 3 grams of carboxymethyl cellulose (CMC) is added to 200 grams of water, then stirred in a vacuum mixer to form a uniform slurry . The slurry was uniformly coated on a 9-micron copper foil, then dried at 100° C., and rolled to obtain a negative electrode sheet with a thickness of 120 microns.

[0086] (2) Preparation of composite negative electrode sheets for lithium-ion batteries

[0087] Al with a particle size of 500nm 2 o 3 Powder and binder polyvinylidene fluoride-cohexafluoropropylene (PVDF-HFP) dispersed in acetone solvent, in which, Al 2 o 3 The mass ratio of powder and PVDF-HFP is 95:5. After grinding for 30 minutes, add polyacrylonitrile fibers with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com