Process for continuously producing epoxy propane through propylene and propane mixed gas directly oxidized by hydrogen peroxide

A technology of propylene oxide and mixed gas, applied in chemical recovery, organic chemistry, etc., can solve the problems of high equipment cost, high process operation pressure, large amount of waste water and waste residue, etc., and achieve the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

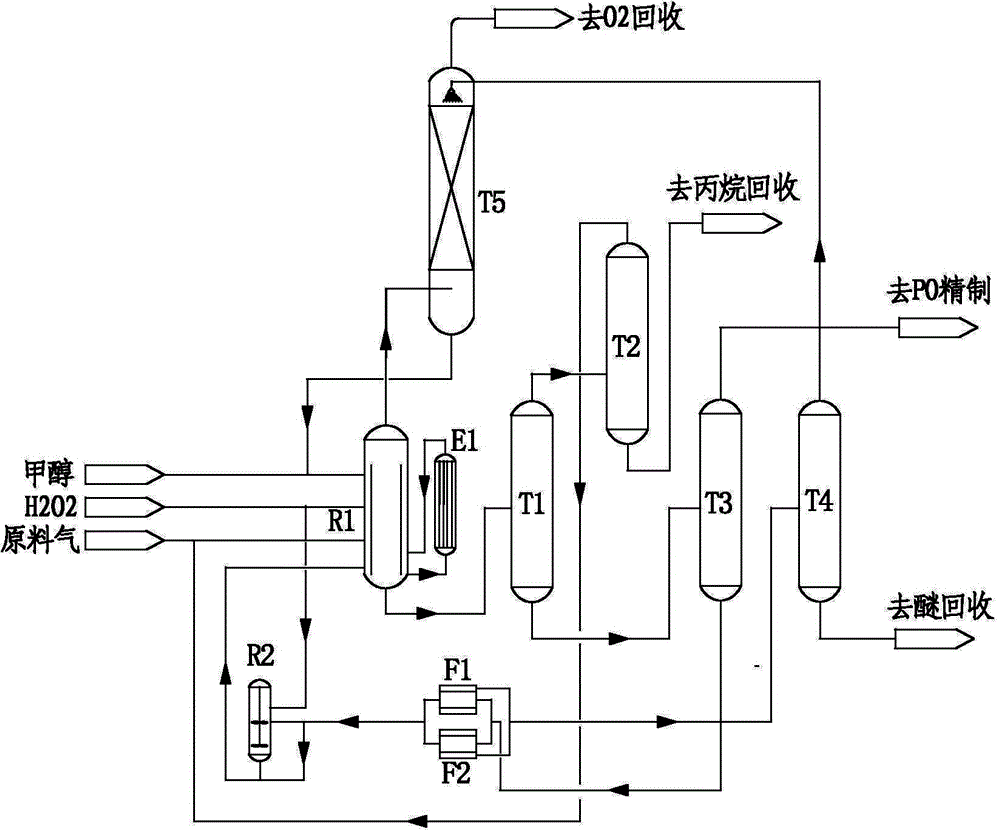

[0027] Such as figure 1Shown flow process, the propylene / propane gas mixture of 500Kg / h (propylene volume content is 90%, and propane volume content is 10%), the mass fraction of 920Kg / h is 27.5% hydrogen peroxide aqueous solution and solvent methyl alcohol, enter flow stream through pipeline respectively The bed loop reactor R1, while the catalyst slurry enters the reactor R1 at a flow rate of 50Kg / h, wherein the molar ratio of propylene:propane:hydrogen peroxide:methanol is 1.43:0.16:1:15, and the reaction temperature of the reactor R1 is 45°C. The reaction pressure is maintained at 1.0MPa, and the unreacted oxypropylene / propane gas mixture is taken out from the top of the reactor R1, and the recovered methanol solvent is used to spray and absorb the oxypropylene in the spray absorption tower T5, and then recycled to the reactor R1, sprayed The operating pressure of the leaching absorption tower T5 is 1.5MPa, and the operating temperature is 0°C. The propylene / propane mixed...

example 2

[0029] Such as figure 1 Shown flow process, the propylene / propane gas mixture of 500Kg / h (the propylene volume content is 80%, and the propane volume content is 20%), the mass fraction of 691Kg / h is 27.5% hydrogen peroxide aqueous solution and solvent methyl alcohol, enter flow stream through pipeline respectively The bed loop reactor R1, while the catalyst slurry enters the reactor R1 at a flow rate of 50Kg / h, wherein the molar ratio of propylene:propane:hydrogen peroxide:methanol is 1.27:0.32:1:15, and the reaction temperature of the reactor R1 is 80°C. The reaction pressure is maintained at 0.2MPa, and the unreacted oxygen-containing propylene / propane mixture gas is extracted from the top of the reactor R1, and the recovered methanol solvent is used to absorb the oxygen-containing propylene in the bubbling absorption tower T5, and then circulated to the reactor R1, and the bubbling absorption The operating pressure of column T5 is 0.8 MPa, and the operating temperature is -...

example 3

[0031] Such as figure 1 Shown flow process, the propylene / propane mixed gas of 500Kg / h (propylene volume content is 70%, and propane volume content is 30%), the mass fraction of 691Kg / h is 27.5% hydrogen peroxide aqueous solution and solvent methyl alcohol, enter flow stream through pipeline respectively The bed loop reactor R1, while the catalyst slurry enters the reactor R1 at a flow rate of 50Kg / h, wherein the molar ratio of propylene:propane:hydrogen peroxide:methanol is 1.11:0.48:1:24, and the reaction temperature of the reactor R1 is 20°C. The reaction pressure is maintained at 0.6MPa, and the unreacted oxygen-containing propylene / propane gas mixture is extracted from the top of the reactor R1, and the recovered methanol solvent is used to absorb the oxygen-containing propylene in the Venturi injector absorption tower T5 and then recycled to the reactor R1. The operating pressure of the Venturi ejector absorption tower T5 is 0.02MPa, and the operating temperature is 30°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com