A method for extracting rutin from Sophora japonica

A technology of Sophora japonica and rutin, applied in chemical instruments and methods, preparation of sugar derivatives, production of bulk chemicals, etc., can solve the problems of reduced production efficiency, rutin being dissolved in hot water, and high cost, and achieves easy operation, The effect of shortening extraction time and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

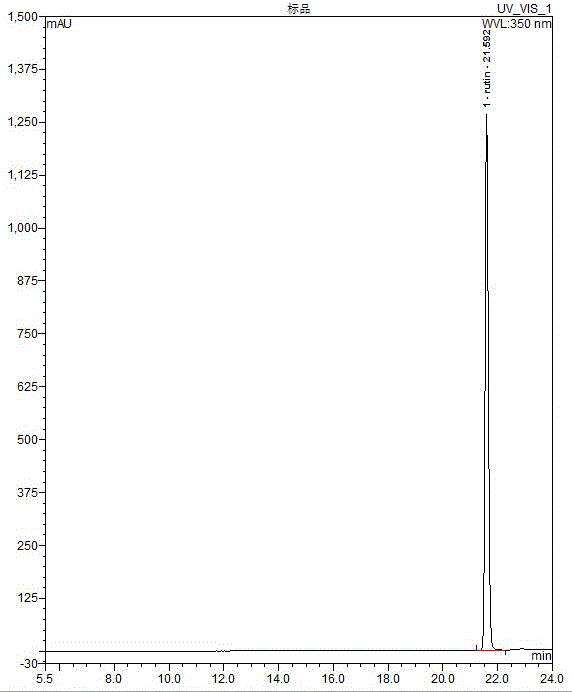

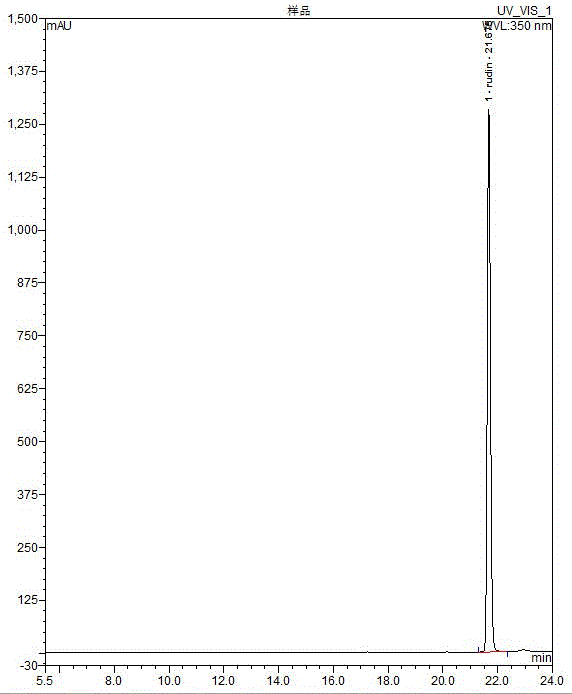

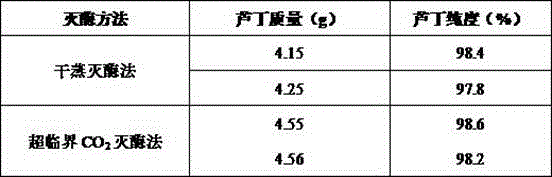

Image

Examples

Embodiment 1

[0016] Crush 20g of Sophora japonica to 30 mesh, add acid water with temperature of 35°C and pH=4~5, stir, put in supercritical CO 2 In the extraction device, treat at 30MPa, 30-40°C for 40min, then wash twice with acid water at 0-5°C, pH=4-5, and dry; add 4% borax to the dried Sophora japonica granules , 1% Na 2 SO 3 and 25 times of 60% ethanol, adding sodium bicarbonate to adjust the pH=9 to 10, ultrasonically extracting at 30kHz and 40°C in the dark for 30min, and then filtering, and the filtrate was kept in the dark at 30°C to 50°C for later use; Ultrasonic extraction was performed once under the same conditions, and the filtrates obtained from the two extractions were combined, 5% activated carbon was added to it, and stirred in the dark at 40°C for 10 minutes, the filtrate was acidified to pH = 4-5 after carbon removal, and 30kHz ultrasonic Treat in the dark at 0-5°C for 30 minutes, let stand to crystallize, and filter to obtain the crude rutin; place the crude rutin i...

Embodiment 2

[0018] Crush 30g of Sophora japonica to 50 mesh, add acid water with temperature of 40°C and pH=4~5, stir, put in supercritical CO 2 In the extraction device, treat at 30MPa, 30-40°C for 40min, then wash twice with acid water at 0-5°C, pH=4-5, and dry; add 3% borax to the dried Sophora japonica granules , 2% Na 2 SO 3 and 20 times of 60% ethanol, adjust the pH=9 to 10 with sodium bicarbonate, and extract it under the conditions of 25kHz and 35°C in the dark for 30 minutes, then filter, and the filtrate is kept in the dark at 30°C to 50°C for later use; Extract once under the same conditions as above, combine the filtrates obtained from the two extractions, add 5% activated carbon to it, and stir in the dark at 40°C for 15 minutes, acidify the filtrate after filtering and removing carbon to pH=4~5, and use a 20~30kHz Ultrasonic treatment at 0-5°C in the dark for 30 minutes, standing for crystallization, and suction filtration to obtain crude rutin; put the crude rutin in an o...

Embodiment 3

[0020] Crush 50g of Sophora japonica to 20 mesh, add acid water with temperature of 35°C and pH=4~5, stir, put in supercritical CO 2 In the extraction device, it was treated at 30MPa and 30-40°C for 40min, then washed twice with acid water at 5°C and pH=4-5, and then dried; add 4% borax, 1 %Na 2 SO 3 and 30 times of 70% ethanol, adjust the pH=9 to 10 with sodium bicarbonate, and extract it under the conditions of 30kHz and 40°C in the dark for 30 minutes, then filter, and the filtrate is kept in the dark at 30°C to 50°C for later use; Ultrasonic extraction once under the same conditions, combined the filtrates obtained from the two extractions, added 5% activated carbon to it, and stirred in the dark at 40°C for 15 minutes, acidified the filtrate after filtering and removing carbon to pH=4~5, and used 20~30kHz Ultrasonic treatment at 0-5°C in the dark for 30 minutes, static crystallization, and suction filtration to obtain crude rutin; put the crude rutin in an oven, dry at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com