Polyamide composition with improved light-heat aging performance

A polyamide composition and photothermal aging technology, applied in the field of polymer materials, can solve the problems of inability to use light-colored or natural-colored products, reducing effect, difficult distribution of stabilizers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

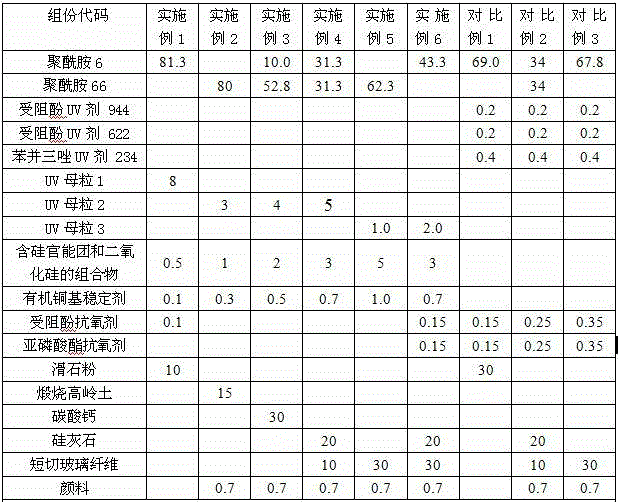

Examples

Embodiment 1-3 and comparative example 1

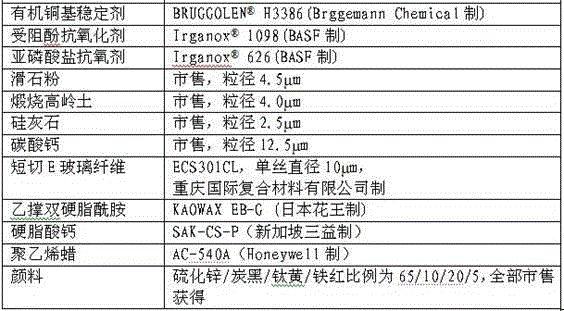

[0099] Add the components of the formula specified in Table 2 from the main feeding port of the extruder, melt and blend at a screw speed of 250-350rpm and a set temperature of 220-260°C, cool, air-dry, pelletize, and mix .

Embodiment 4-6 and comparative example 2-3

[0101] Add the ingredients specified in Table 2 from the main feeding port of the extruder except the chopped E-glass fiber, and add the chopped E-glass fiber from the side feeding port at 250-350rpm screw speed and 220-260℃ Melting and blending at a set temperature, cooling, air-drying, pelletizing, and mixing.

[0102] The obtained example and comparative example particles were dried at a temperature of 80°C-100°C for 4 hours to ensure that the moisture content of the particles was lower than 0.15%, and then the samples were prepared.

[0103]The injection molded samples were prepared according to the ASTM D4066 standard, the melt temperature was set at 290°C, and the mold temperature was set at 80°C.

[0104] The long-term photothermal aging resistance is carried out according to ASTM G154 Cycle 1, the conditions are: the wavelength of ultraviolet light is 340nm, the irradiation intensity is 0.89W (m2-nm), and the irradiation cycle is 8 hours of ultraviolet irradiation / bl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com