Method for determining content of metallic magnesium in briquetting nodulizer through subtraction process

A technology of metal magnesium and nodularizing agent, which is applied in chemical analysis by titration method and weighing by removing certain components, can solve the problems of long analysis time, complicated analysis steps, affecting metal magnesium complex titration, etc. To achieve the effect of simplifying analysis steps, reducing pollution, and reducing laboratory costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Further illustrate the technical scheme of the present invention by the following examples: the assay method of metal magnesium content in the low-silicon briquetting nodulizer, but content of the present invention is not only limited to following examples:

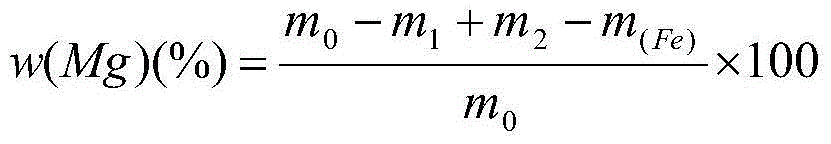

[0025] (1) Accurately weigh 10.0000g of nodulizer sample into a 500mL beaker, add 200mL of dilute acetic acid (1+9), shake fully at room temperature for 20min until the metal magnesium is completely dissolved. Use slow filter paper to filter in a 500mL volumetric flask, transfer all the residue to the filter paper, and rinse the beaker and the residue on the filter paper with pure water for 3 to 5 times. Dilute to the mark with water and mix well;

[0026] (2) Put the filter paper and the residue together in a vacuum oven at 90°C for 1 hour to quickly dry, take it out and put it in a desiccator to cool to room temperature, and then quickly weigh it as m 1 , where the mass of the filter paper is m 2 ;

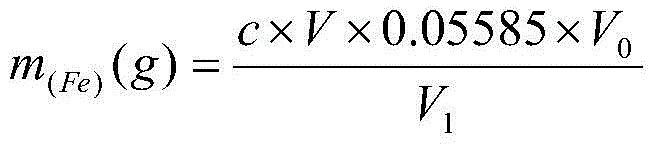

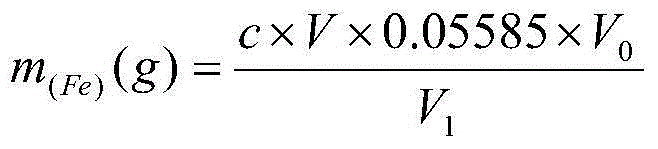

[0027] (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com