Method for preparing efficient function material easy to separate and used for wastewater treatment

A functional material and wastewater treatment technology, which is applied in the field of chemical industry, achieves the effect of wide range of action, reduction of heavy metal content and COD value, and reduction of difficulty and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for preparing an efficient and easy-to-separate functional material for wastewater treatment, comprising the following steps:

[0032] (1) Take 12g of cobalt nitrate and 10g of chitosan, add it to 1kg of acetic acid solution with a mass concentration of 2%, and ultrasonically treat it for 10 minutes; it can achieve the purpose of mixing evenly;

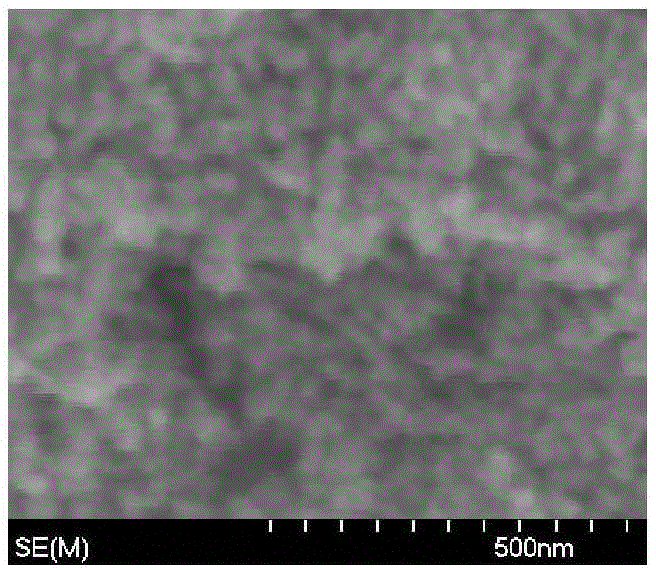

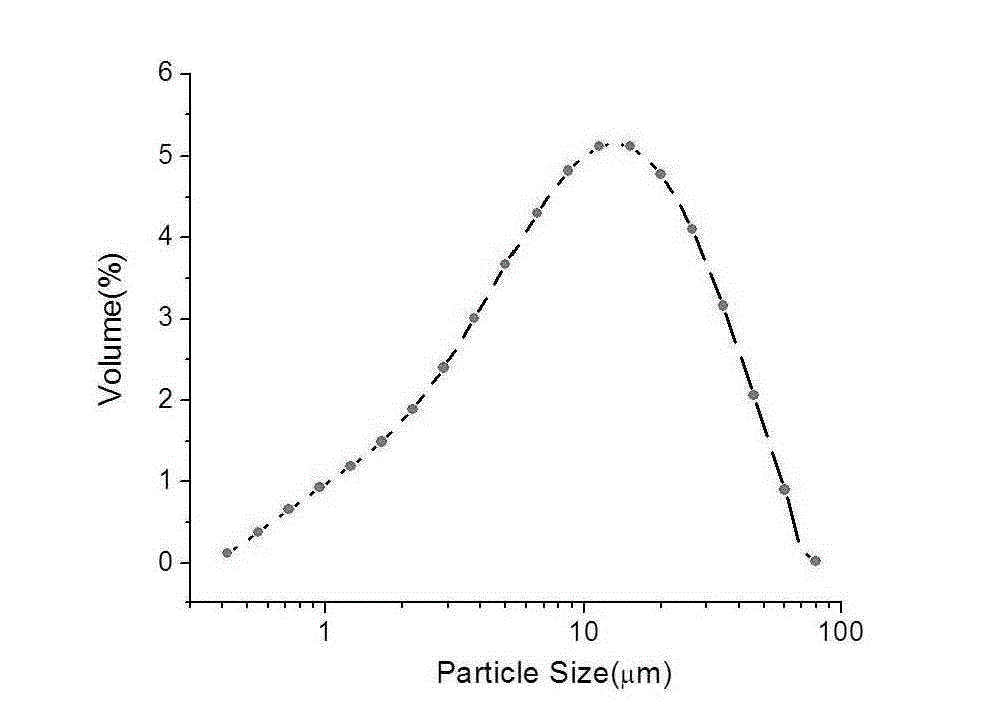

[0033] (2) Spray-dry the mixed solution obtained in step (1) to obtain yellow-brown solid particles; wherein, the spray-drying adopts the centrifugal spray-drying method, and the inlet temperature is set at 180°C to obtain yellow-brown solid particles with a particle size distribution of 5~ 20 micron interval; half decomposition of cobalt nitrate can be realized;

[0034] (3) Put the solid particles into the ceramic boat, move them into the corundum tube in the high temperature tube furnace, first seal the corundum tube and vacuumize it, and then pass in nitrogen for 30 minutes, then change the atmosphere to 100ml / min ...

Embodiment 2

[0040] A method for preparing an efficient and easy-to-separate functional material for wastewater treatment, comprising the following steps:

[0041] (1) Take 5g of cobalt nitrate and 5g of chitosan, add it to 0.5kg of acetic acid solution with a mass concentration of 4%, and ultrasonically treat it for 5 minutes; it can achieve the purpose of mixing evenly;

[0042] (2) Spray-dry the mixed solution obtained in step (1) to obtain yellow-brown solid particles; wherein, the spray-drying adopts the centrifugal spray drying method, and the inlet temperature is set at 150°C to obtain yellow-brown solid particles with a particle size distribution of 5~ 20 micron interval; half decomposition of cobalt nitrate can be realized;

[0043] (3) Put the solid particles into the ceramic boat, move them into the corundum tube in the high temperature tube furnace, first seal the corundum tube and vacuumize it, and then pass in nitrogen for 25 minutes, then change the atmosphere to 80ml / min ni...

Embodiment 3

[0047] A method for preparing an efficient and easy-to-separate functional material for wastewater treatment, comprising the following steps:

[0048] (1) Take 15g of cobalt nitrate and 10g of chitosan, add it to 2kg of acetic acid solution with a mass concentration of 2%, and ultrasonically treat it for 15 minutes; it can achieve the purpose of mixing evenly;

[0049] (2) Spray-dry the mixed solution obtained in step (1) to obtain yellow-brown solid particles; wherein, the spray-drying adopts the centrifugal spray-drying method, and the inlet temperature is set to 200°C to obtain yellow-brown solid particles with a particle size distribution of 5~ 20 micron interval; half decomposition of cobalt nitrate can be realized;

[0050] (3) Put the solid particles into the ceramic boat, move them into the corundum tube in the high temperature tube furnace, first seal the corundum tube and evacuate it, then pass in nitrogen for 40 minutes, then change the atmosphere to 120ml / min nitro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com