Method for preparation of aluminum hydroxide by gas-solid technique

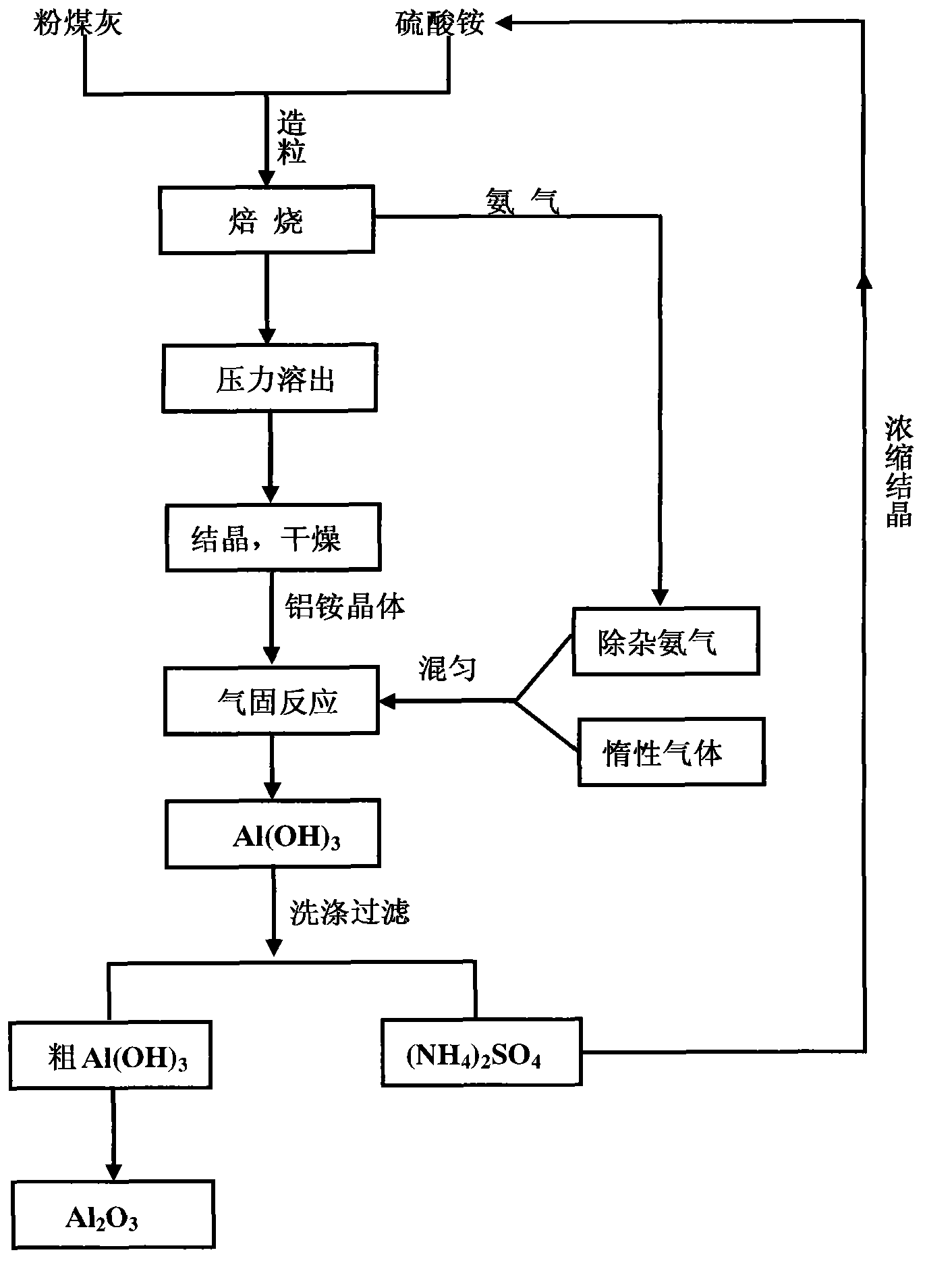

A technology of aluminum hydroxide and aluminum oxide, applied in the direction of aluminum oxide/aluminum hydroxide, etc., can solve the problems of long aging time, slow reaction speed, slow pH value control of ammonium aluminum sulfate solution, etc., and achieve easy control of reaction conditions, The effect of fast reaction speed and high conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Fly ash and ammonium sulfate are uniformly mixed and granulated, dried at 120°C, and roasted at 450°C for 1.5 hours. The ratio of fly ash to ammonium sulfate is expressed by the molar ratio of alumina and ammonium sulfate contained in fly ash. The molar ratio of alumina and ammonium sulfate contained in the fly ash is Al 2 o 3 :(NH 4 ) 2 SO 4 =1:5.3, take 300g of the clinker obtained under the above conditions and add water to dissolve in the autoclave, the dissolution pressure is 0.15Mpa, the dissolution time is 30min, and the dissolution filtrate is filtered and removed at room temperature (25°C) at 10r / min. Stir to obtain aluminum ammonium sulfate crystals with an average particle size of 40 mesh, dry them with hot air at 90°C for 8 minutes, take 50 g of the crystals and place them in a gas-solid reactor, and feed nitrogen gas with a flow rate of 66 L / min and ammonia gas with a flow rate of 40 L / min. , and the temperature of the gas phase is controlled by a gas h...

Embodiment 2

[0025] Fly ash and ammonium sulfate were uniformly mixed and granulated, dried at 120°C, and roasted at 410°C for 2 hours. The proportion of fly ash and ammonium sulfate was expressed by the molar ratio of alumina and ammonium sulfate contained in fly ash. The molar ratio of aluminum oxide and ammonium sulfate contained in the fly ash is Al 2 o 3 :(NH 4 ) 2 SO 4 =1:3.5, take 300g of roasted clinker under the above conditions and add water to dissolve in the autoclave, the dissolution pressure is 0.5Mpa, the dissolution time is 40min, and the dissolution filtrate is filtered and slag-removed at 15°C under 50r / min constant stirring, The average particle size obtained is 60 mesh aluminum ammonium sulfate crystals, dried with 40°C hot air for 20 minutes, 50 g of the crystals are taken and placed in a gas-solid reactor, and the flow rate is 5 L / min of nitrogen, 30 L / min of ammonia, and The temperature of the gas phase is controlled by a gas heater to be 35°C, and the ammonium a...

Embodiment 3

[0027] Fly ash and ammonium sulfate are uniformly mixed and granulated, dried at 120°C, and roasted at 440°C for 2.5 hours. The proportion of fly ash and ammonium sulfate is expressed by the molar ratio of alumina and ammonium sulfate contained in fly ash. The molar ratio of alumina and ammonium sulfate contained in the fly ash is Al 2 o 3 :(NH 4 ) 2 SO 4 =1:3.5 Take 300g of fly ash and ammonium sulfate roasting clinker under the above conditions, add water to dissolve in an autoclave, the dissolution pressure is 1Mpa, and the dissolution time is 1h. Stir to obtain aluminum ammonium sulfate crystals with an average particle size of 80 mesh, dry them with hot air at 65°C for 10 minutes, take 50 g of the crystals and place them in a gas-solid reactor, and feed in flow rates of 20 L / min nitrogen and 10 L / min ammonia. The temperature of the gas phase is controlled by a gas heater to be 40°C, and the aluminum ammonium sulfate crystals react under fluidized conditions. After 5 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com