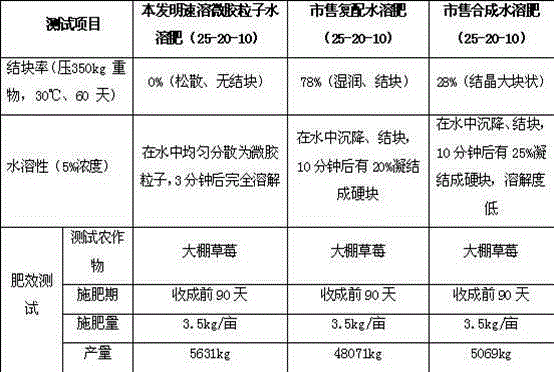

A kind of instant microparticle water-soluble fertilizer and preparation method thereof

A water-soluble fertilizer and particle technology, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of slow dissolution, agglomeration, easy loss of fertilizer ions, etc., and achieve the effect of preventing deliquescence and preventing the loss of fertilizer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Mix emulsified paraffin wax and polydimethylaminobenzylethyl methacrylate in a mass ratio of 2:1 in a continuous vortex jet mill and pass through a 50-mesh sieve to obtain a powdery surface protective agent;

[0040] (2) 97 parts by weight of ammonium dihydrogen phosphate and 3 parts by weight of surface protection agent, 95 parts by weight of potassium sulfate and 5 parts by weight of surface protection agent, 96 parts by weight of magnesium sulfate and 4 parts by weight of surface protection agent , 95 parts by weight of manganese sulfate and 5 parts by weight of surface protection agent are respectively ground by a double-barrel vibrating mill, and the rotating speed is 200-350r / min. The medium is strongly impacted and ground under the action of grinding, and the fertilizer nutrient raw material particles are composed of micro-cracks. The balance of the surface gradually moves to the discharge port, and the microcolloid particles are obtained through classificati...

Embodiment 2

[0043] (1) Mix emulsified beeswax and polyimidazolidinyl ketone hydroxyethyl methacrylate in a mass ratio of 4:1 in a continuous vortex jet mill to pass through a 50-mesh sieve to obtain a powdery surface protection agent;

[0044] (2) 96 parts by weight of potassium dihydrogen phosphate and 4 parts by weight of surface protection agent, 95 parts by weight of ammonium monohydrogen phosphate and 5 parts by weight of surface protection agent, 97 parts by weight of ammonium dihydrogen phosphate and 3 parts by weight of The surface protection agent, 97 parts by weight of zinc sulfate and 3 parts by weight of the surface protection agent are respectively ground by a double-barrel vibrating mill at a speed of 200-350r / min. During the vibration process, the fertilizer nutrient raw materials and the surface protection agent are in the cylinder As the grinding medium is strongly impacted and ground under the action of grinding, the fertilizer nutrient raw material particles appear defec...

Embodiment 3

[0047] (1) Mix emulsified montan wax and polyacrylic methacrylate in a mass ratio of 5:1 in a continuous vortex jet mill and pass through a 50-mesh sieve to obtain a powdery surface protection agent;

[0048] (2) 97 parts by weight of ammonium dihydrogen phosphate and 3 parts by weight of surface protection agent, 95 parts by weight of potassium chloride and 5 parts by weight of surface protection agent, 96 parts by weight of calcium chloride and 4 parts by weight of surface The protective agent, the borax of 95 parts by weight and the surface protective agent of 5 parts by weight, the copper sulfate of 95 parts by weight and the surface protective agent of 5 parts by weight are respectively ground by double-barrel vibrating mill, and the rotating speed is 200-350r / min. In the process, the fertilizer nutrient raw material and the surface protective agent are ground in the cylinder under the strong impact and grinding action of the grinding medium, and the fertilizer nutrient ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com