High-silicon MFI zeolite adsorbent without adhesive and preparation method thereof

A binder-free and adsorbent-free technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor separation effect, low adsorption rate, and small adsorption capacity, achieve high para-selectivity, reduce bed The number of layers and the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

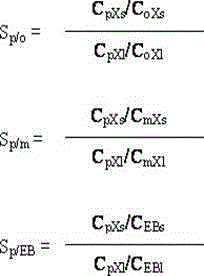

Method used

Image

Examples

Embodiment 1

[0031] Weigh silica sol (by weight percentage, containing 40%SiO 2 ) 9.0 kg, in a 30-liter reactor, add 9.0 kg of tetrapropylammonium hydroxide (TPAOH) solution (by weight percent, containing 20% tetrapropylammonium hydroxide), stir for 30 minutes, then add MFI 360 grams of zeolite seed crystals (200 nanometers), continued to stir for 8 hours, then continued to stir, raised the temperature of the crystallization kettle to 160° C., and crystallized for 28 hours. The product was taken out, filtered, washed with deionized water until neutral, and dried at 120°C for 6 hours to obtain high-silicon MFI zeolite powder 1. The properties of the powder are shown in Table 1.

[0032] Weigh 1.0 kg of powder 1, 0.030 kg of carboxymethyl cellulose, mix the above powder evenly, add 0.15 kg of water glass containing 10% sodium silicate by weight percentage, roll into a ball, and sieve the formed silicon ball , select 16-40 mesh silicon balls, that is, the adhesive-containing adsorbent; the...

Embodiment 2

[0039] Weigh ethyl silicate (by weight percent, containing 28.8%SiO 2 ) 12.5 kg, in a 30-liter reactor, add 9.0 kg of tetrapropylammonium bromide (TPABr) solid, add 19.5 kg of water, add 4.8 kg of sodium hydroxide (solid), stir for 30 minutes, and then add MFI zeolite seed ( 200 nanometers) 360 grams, continue to stir for 8 hours, continue to stir, raise the temperature of the crystallization kettle to 140°C, and crystallize for 48 hours. The product was taken out, filtered, washed with deionized water until neutral, and dried at 120°C for 6 hours to obtain high-silicon MFI zeolite powder 2. The properties of the powder are shown in Table 1.

[0040] Weigh 1.0 kg of powder 2, 0.02 kg of methyl cellulose, mix the above powder evenly, add 0.30 kg of water glass containing 10% sodium silicate in weight percentage, roll into a ball, and sieve the formed silicon ball. Select 20-40 mesh silicon balls, that is, the adhesive-containing adsorbent; the adhesive is transformed into a cr...

Embodiment 3

[0044] Weigh silica gel (SiO 2 ) 3.6 kg, in a 160-liter reactor, add 1.62 kg of ethylenediamine, add 108 kg of water, add 4.8 kg of sodium hydroxide (solid), stir for 30 minutes, then add 360 g of MFI zeolite seed crystals (200 nanometers), continue After stirring for 8 hours, continue stirring, raise the temperature of the crystallization tank to 170° C., and crystallize for 28 hours. The product was taken out, filtered, washed with deionized water until neutral, and dried at 120°C for 6 hours to obtain high-silicon MFI zeolite powder 3. The properties of the powder are shown in Table 1.

[0045] Weigh 1.0 kg of powder 3, 0.10 kg of hydroxymethyl cellulose, mix the above powder evenly, add 0.03 kg of water glass containing 10% sodium silicate by weight percentage, roll into a ball, and sieve the formed silicon ball , select 16-30 mesh silicon balls, that is, the adhesive-containing adsorbent; the adhesive is transformed into a crystal, and the adhesive-containing adsorbent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com