A preparation method of bismuth oxyfluoride/graphene composite visible light catalyst

A graphene composite and bismuth oxyfluoride technology, which is applied in the direction of light water/sewage treatment, energy wastewater treatment, etc., can solve the problems of no discovery, etc., and achieve the effects of stable performance, strong market application prospects, and wide absorption spectrum range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

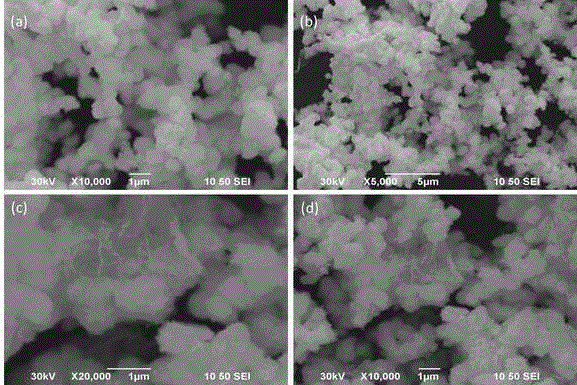

Embodiment 1

[0014] 2.5mmol Bi(NO 3 ) 3 ∙5H 2 O was added to 20 mL ethylene glycol, and until it was completely dissolved, solution X was obtained; 2.5 mmol NaF was dissolved in 20 mL ethylene glycol, and solution Y was obtained after it was completely dissolved; solution X and solution Y were mixed dropwise (approx. 2mL / min) by adding 100mL deionized water to obtain a white precipitate, which was filtered, washed with deionized water and ethanol three times each, and the filtered product was dried in a constant temperature drying oven at 80°C for 5h, and then kept at 300°C for 2h to obtain A spherical bismuth oxyfluoride photocatalyst with a particle size of 800nm. The RhB removal rate of Rhodamine B dye wastewater was degraded under natural sunlight for 8 hours was 50%.

Embodiment 2

[0016] 2.5mmol Bi(NO 3 ) 3 ∙5H 2 O was added to 20 mL ethylene glycol, and until it was completely dissolved, solution X was obtained; 2.5 mmol NaF was dissolved in 20 mL ethylene glycol, and solution Y was obtained after it was completely dissolved; solution X and solution Y were mixed dropwise (approx. 2mL / min) by adding 100mL deionized water to obtain a white precipitate, which was filtered, washed with deionized water and ethanol three times each, and the filtered product was dried in a constant temperature drying oven at 80°C for 5h, and then kept at 300°C for 2h to obtain Spherical bismuth oxyfluoride with a particle size of 800nm; add 1.52mg of graphene oxide into 50mL of deionized water, ultrasonically disperse for 60min to form a graphene oxide aqueous solution, add 2.5mmol spherical bismuth oxyfluoride to the graphene oxide aqueous solution, and continue to Stir for 2 hours; then transfer to a constant temperature water bath, add 0.025mL hydrazine hydrate, reduce t...

Embodiment 3

[0018] 2.5mmol Bi(NO 3 ) 3 ∙5H 2 O was added to 20 mL ethylene glycol, and until it was completely dissolved, solution X was obtained; 2.5 mmol NaF was dissolved in 20 mL ethylene glycol, and solution Y was obtained after it was completely dissolved; solution X and solution Y were mixed dropwise (approx. 2mL / min) by adding 100mL deionized water to obtain a white precipitate, which was filtered, washed with deionized water and ethanol three times each, and the filtered product was dried in a constant temperature drying oven at 80°C for 5h, and then kept at 300°C for 2h to obtain Spherical bismuth oxyfluoride with a particle size of 800nm; add 3.05mg of graphene oxide into 50mL of deionized water, ultrasonically disperse for 60min to form a graphene oxide aqueous solution, add 2.5mmol spherical bismuth oxyfluoride to the graphene oxide aqueous solution, and continue to Stir for 2 hours; then transfer to a constant temperature water bath, add 0.05mL hydrazine hydrate, reduce th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com