A kind of preparation method of chitin organic fertilizer

A technology of organic fertilizer and chitin, which is applied in the preparation of organic fertilizers, organic fertilizers, and the treatment of biological organic parts, etc., can solve the problems of low efficiency and troublesome operation process, and achieve the effect of simple operation, low cost and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of chitin organic fertilizer, comprising the following specific steps:

[0045] a. Raw material pretreatment: dry crustacean raw materials such as shrimp, crab, and pupae, and crush them through a sieve smaller than 6mm for later use;

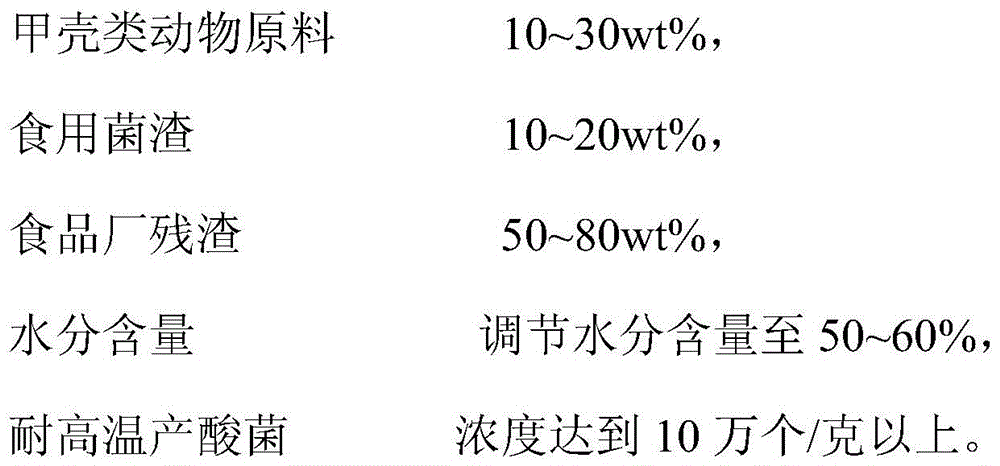

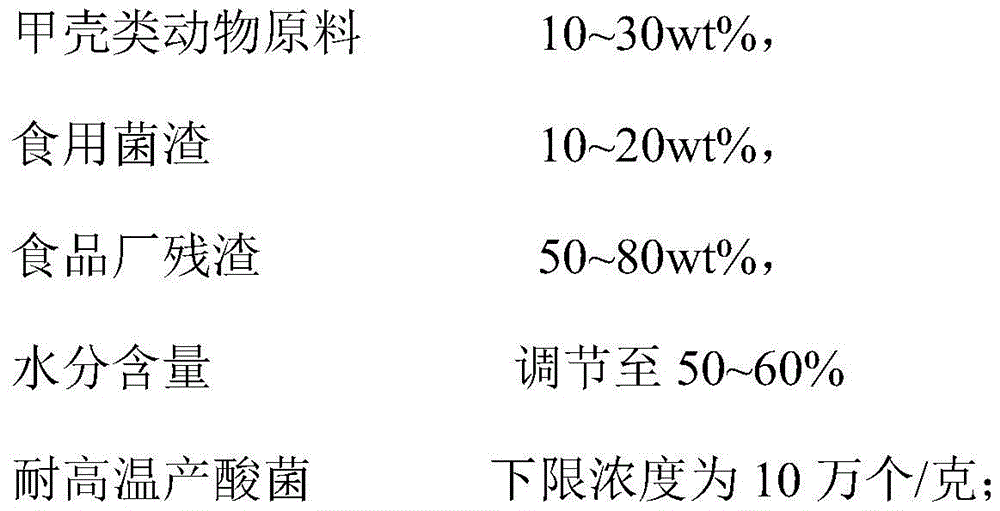

[0046] b, anaerobic fermentation: mix 10-30% crushed crustacean raw material on a dry basis mass with 10-20% edible fungus residue on a dry basis mass, and 50-80% food factory residue on a dry basis mass, Adjust the moisture content to 50-60%, then add high-temperature-resistant acid-producing bacteria and mix evenly to make the concentration reach more than 100,000 per gram, and seal the anaerobic fermentation for 10-30 days after stacking until the pH value is lower than 4.5;

[0047] c. Aerobic fermentation: Use urea, ammonium carbonate or ammonium bicarbonate to adjust the carbon-to-nitrogen ratio to less than 20:1 for the anaerobic fermented stock, and then add Aspergillus niger, Bacillus, actinomycetes and yeas...

Embodiment 1

[0050] a. Crustacean raw materials such as shrimp, crab and pupa are dried and crushed through a sieve less than 5mm for subsequent use;

[0051] b. Mix 30% of the crushed crustacean raw material on a dry basis with 20% of the edible fungus residue on a dry basis and 50% of the food factory residue on a dry basis, adjust the moisture content to 50%, and then add resistant The high-temperature acid-producing bacteria are mixed evenly so that the concentration reaches 150,000 per gram, and the pH value is lower than 4.5 when the material is sealed and anaerobically fermented for 15 days after stacking;

[0052] c. Add 5 kg of urea to the anaerobically fermented stockpile to adjust the carbon-to-nitrogen ratio to 15:1, and then add Aspergillus niger, Bacillus, actinomycetes and yeast to a ratio of 1 : 50:1:1 mixed decomposing agent for organic materials, mix evenly to make the concentration 600,000 per gram of raw materials, carry out aerobic fermentation, turn over the heap duri...

Embodiment 2

[0054] a. Shrimp, crab, pupa and other crustacean raw materials are dried and crushed through a sieve less than 4mm for subsequent use;

[0055] b. Mix 20% of the crushed crustacean raw material on a dry basis with 10% of the edible fungus residue on a dry basis and 70% of the food factory residue on a dry basis, adjust the moisture content to 55%, and then add resistant The high-temperature acid-producing bacteria are mixed evenly, and the concentration reaches 100,000 per gram of raw material. After stacking and sealing anaerobic fermentation for 25 days, the pH value is lower than 4.5;

[0056] c. Add 10 kg of urea to the anaerobically fermented stockpile to adjust the carbon-to-nitrogen ratio to 10:1, and then add Aspergillus niger, spores, actinomycetes and yeasts in a ratio of 2 : 50:2:2 organic material decomposing agent, mix evenly so that the concentration is 600,000 per gram of raw material, carry out aerobic fermentation, turn over the pile during aerobic fermentati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com