Water-based color transparent heat-insulating coating, preparation method and application method thereof

A thermal insulation coating, water-based technology, applied in multi-color effect coatings, reflective/signal coatings, coatings, etc., can solve the problems of easy agglomeration, limited use, low hardness, etc., to improve thermal insulation effect, enhance aging resistance , Enhance the effect of thermal insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

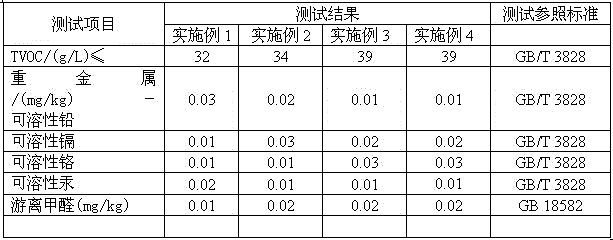

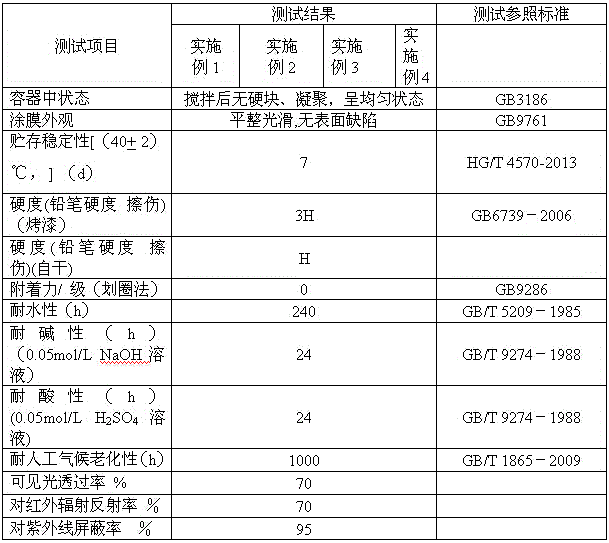

Examples

Embodiment 1

[0054] 1. To prepare water-soluble hydroxyacrylic resin, the synthesis process is as follows.

[0055] A. Add 185 grams of n-butanol, 90 grams of anti-white water and 10 grams of polyester resin 1181 / 03 in a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and heat up to 130°C.

[0056] B. Mix 50 grams of methyl methacrylate (MMA), 140 grams of β-hydroxyethyl methacrylate (HEMA), 160 grams of butyl acrylate (BA), 30 grams of acrylic acid (AA), 2 g of dodecylmercaptan (C 12 h 25 SH) and 13.5 grams of benzoyl peroxide (BPO) were mixed evenly, and the mixed raw materials were added dropwise to the four-necked flask at a constant speed, ensuring that the dropwise addition was completed within 3~4 hours.

[0057] C. Keep warm for 1 hour, add 1.5 grams of benzoyl peroxide (BPO), and keep warm for another 2 hours.

[0058] D. Add 28 grams of maleic anhydride into the reactor and keep it warm for 2~2.5h.

[0059] E. Cool down to 60~70°C, add 40 gram...

Embodiment 2

[0073] 1. To prepare water-soluble hydroxyacrylic resin, the synthesis process is as follows.

[0074] A. Add 185 grams of n-butanol, 105 grams of anti-white water and 20 grams of polyester resin 1181 / 03 in a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and heat up to 130°C.

[0075] B. Mix 110 grams of methyl methacrylate (MMA), 80 grams of β-hydroxyethyl methacrylate (HEMA), 105 grams of butyl acrylate (BA), 15 grams of acrylic acid (AA), 5 g of dodecylmercaptan (C 12 h 25 SH) and 40.5 grams of benzoyl peroxide (BPO) were mixed evenly, and the mixed raw materials were added dropwise to the four-necked flask at a constant speed, ensuring that the dropwise addition was completed within 3 to 4 hours.

[0076] C. Keep warm for 1 hour, add 4.5 grams of benzoyl peroxide (BPO), and keep warm for another 2 hours.

[0077] D. Add 30 grams of maleic anhydride into the reactor and keep it warm for 2~2.5h.

[0078] E. Cool down to 60~70°C, add 40 ...

Embodiment 3

[0092] 1. To prepare water-soluble hydroxyacrylic resin, the synthesis process is as follows.

[0093] A. Add 197 grams of n-butanol, 90 grams of anti-white water and 50 grams of polyester resin 1181 / 03 in a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, and raise the temperature to 130°C.

[0094] B. Mix 50 grams of methyl methacrylate (MMA), 80 grams of β-hydroxyethyl methacrylate (HEMA), 105 grams of butyl acrylate (BA), 15 grams of acrylic acid (AA), 3 g of dodecylmercaptan (C 12 h 25 SH) and 13.5 grams of benzoyl peroxide (BPO) were mixed evenly, and the mixed raw materials were added dropwise to the four-necked flask at a constant speed, ensuring that the dropwise addition was completed within 3~4 hours.

[0095] C. Keep warm for 1 hour, add 1.5 grams of benzoyl peroxide (BPO), and keep warm for another 2 hours.

[0096] D. Add 55 grams of maleic anhydride into the reactor and keep it warm for 2~2.5h.

[0097] E. Cool down to 60~70°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com