Multipoint-type catalytic biomass gasification machine

A biomass, multi-point technology, applied in the production of bulk chemicals, the manufacture of combustible gas, the petroleum industry, etc., can solve the problems of reducing the utilization rate of biomass raw materials, increasing the consumption of gas caused by cracking, and damage to gas utilization equipment, etc. The effect of reducing temperature, avoiding gas consumption, and leveling raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

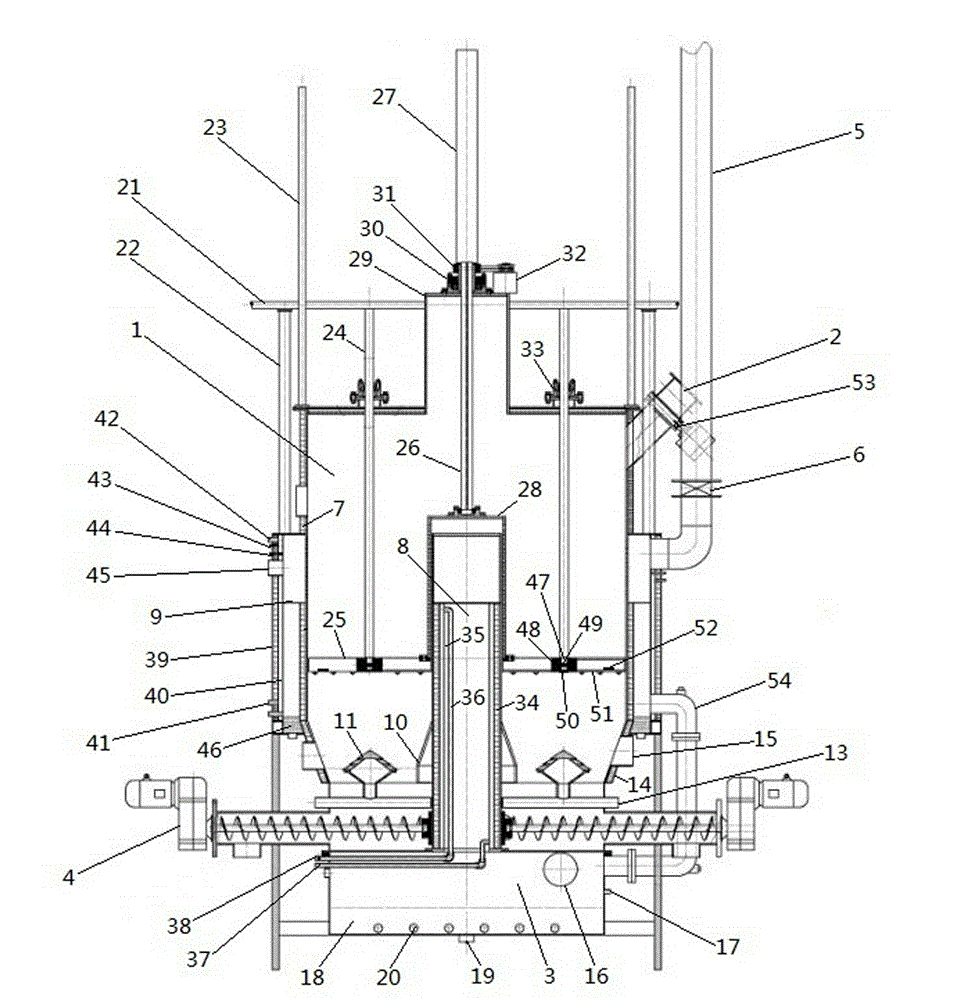

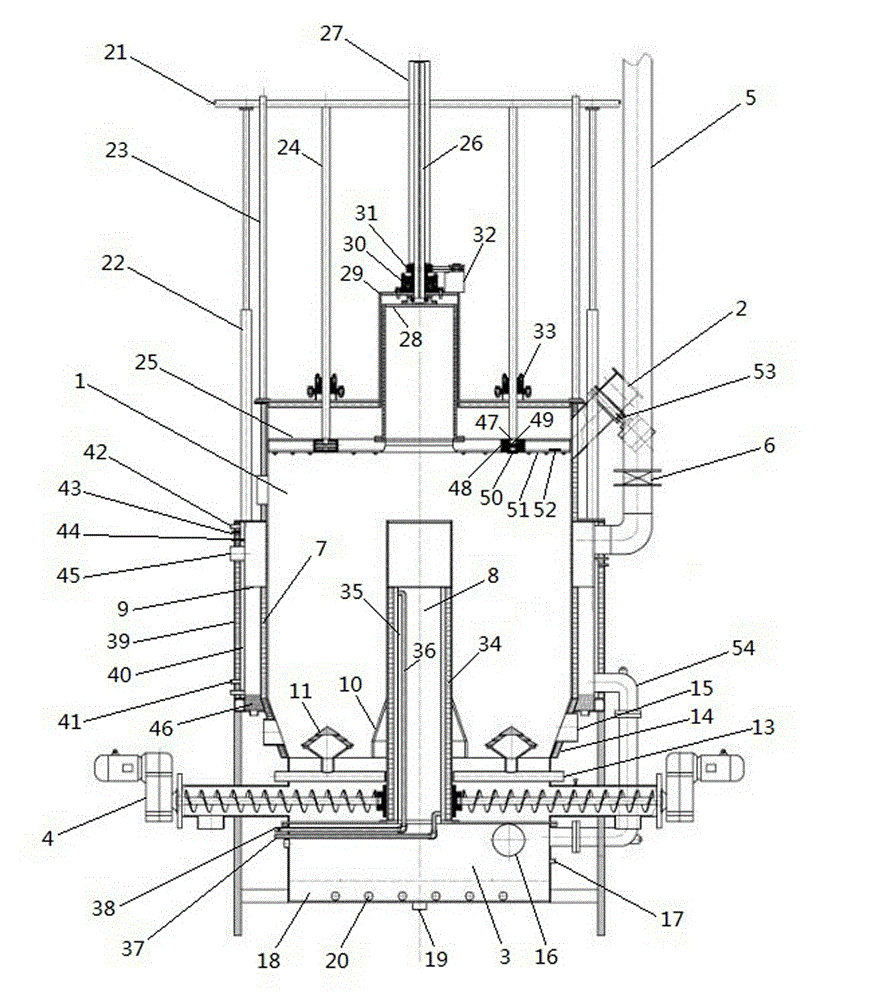

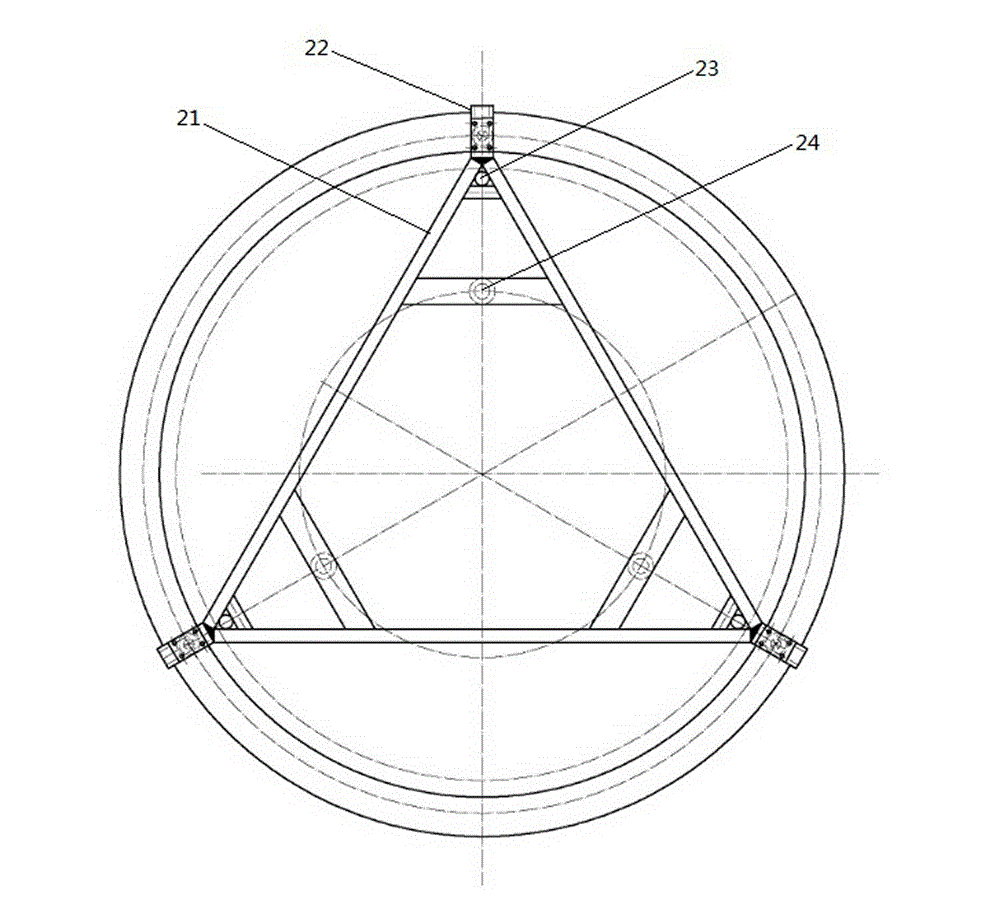

[0023] Example 1, such as figure 1 , figure 2 , image 3 , Figure 4As shown, a multi-point catalytic biomass gasifier includes a fuel bin 1, a feed port 2 arranged on the side of the fuel bin 1, a mixed gas bin 3 arranged at the lower part of the fuel bin 1, and a mixing chamber 3 arranged at the fuel bin 1 and The automatic slag discharge machine 4 between the gas bins 3, the top of the fuel bin 1 is equipped with a pressing system, the convection chimney 5 is installed under the feeding port 2, the vacuum butterfly valve 6 is installed on the convection chimney 5, and the inner wall of the fuel bin 1 is equipped with an internal insulation Layer 7, an inner cooling gas bin 8 is arranged in the middle of the fuel bin 1, an outer cooling gas bin 9 is arranged on both sides of the fuel bin 1, a trapezoidal combustion chamber 10 is arranged in the middle of the bottom of the fuel bin 1, and tower-type cooling chambers are arranged around the trapezoidal combustion chamber 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com