Composite magnesium oxide film applied to plasma display panel and preparation method and application thereof

A display panel, magnesium oxide technology, which is applied in cold cathode manufacturing, electrode system manufacturing, discharge tube/lamp manufacturing, etc., can solve the problems of high production cost and low utilization rate of raw materials, and achieve enhanced and improved sputtering resistance. Display brightness and display quality, the effect of high process efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

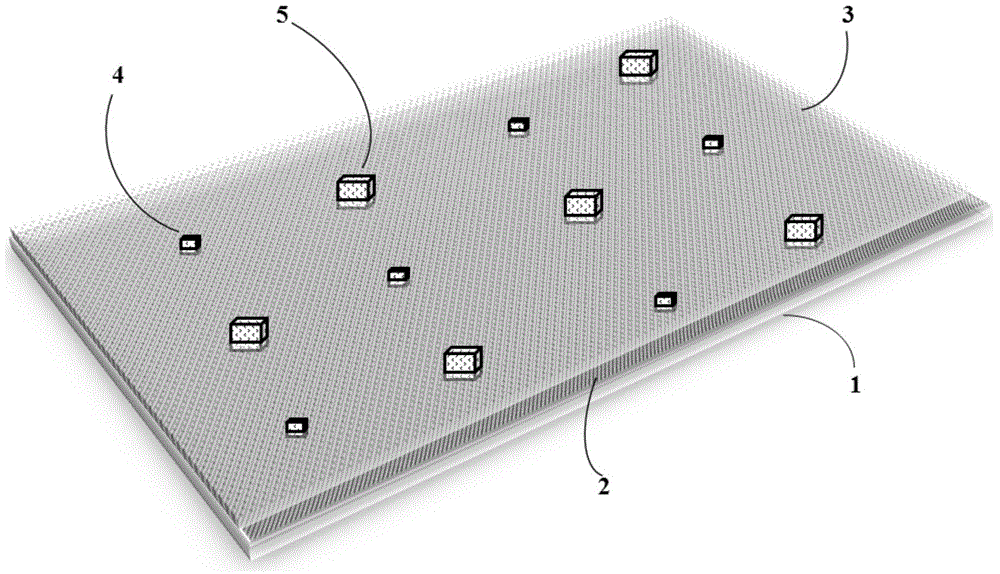

[0046] The preparation method of composite magnesium oxide thin film of the present invention comprises the following steps:

[0047] (1) coating the coating solution A on the surface of the substrate (1), and drying to obtain a film a;

[0048] (2) coating the coating solution B on the film a to prepare the film b;

[0049] (3) obtain composite magnesium oxide film after annealing;

[0050] Wherein, the coating liquid A is prepared by aging a mixed liquid containing magnesium salt, dispersant, stabilizer and organic solvent, and the coating liquid B is made of magnesium oxide microcrystalline particles or doped magnesium oxide microcrystalline The particles are dispersed in the same solution as coating solution A;

[0051] When coating liquid B contains magnesium oxide microcrystalline particles, the molar ratio of magnesium in film b to film a is 0.2 to 25:1; when coating liquid B contains doped magnesium oxide microcrystalline particles, the film The molar ratio of the m...

Embodiment 1

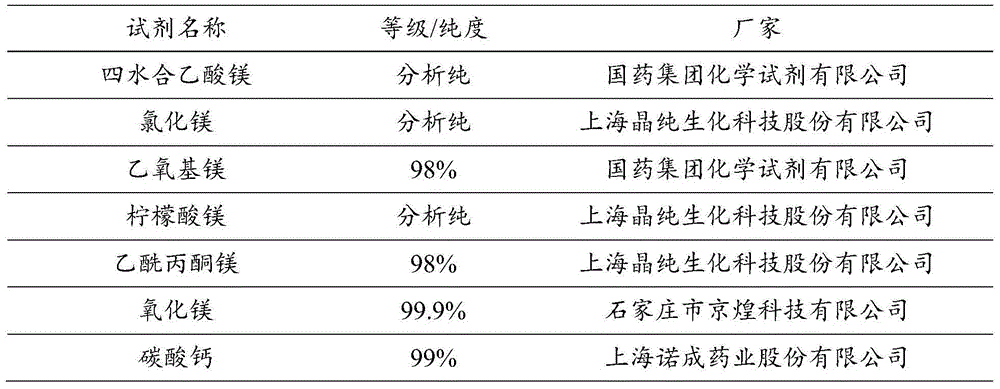

[0060] Preparation of coating solution A: Weigh 5.35g of magnesium acetate tetrahydrate, dissolve it in 62.5mL of absolute ethanol, stir and dissolve fully, then add 0.75g of glacial acetic acid and polyethylene glycol 400 (the amount is 5% of the mass of the magnesium salt). %), mixed evenly, stirred and aged for 24h to obtain coating solution A;

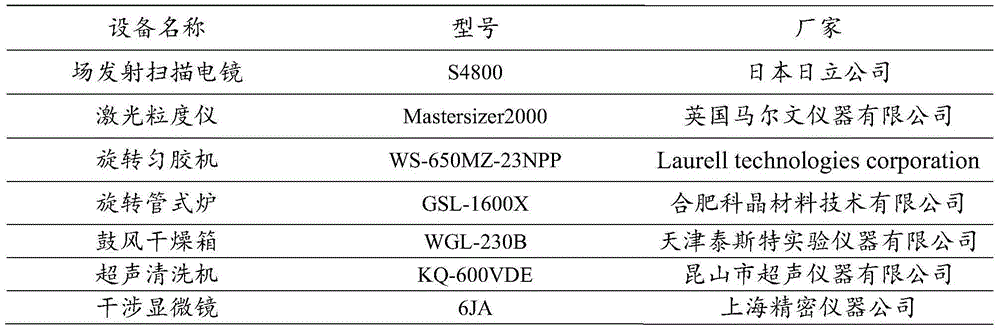

[0061] Preparation of coating liquid B: take 10 g of the above coating liquid A, add 1 g of calcium oxide magnesium microcrystalline particles, and obtain coating liquid B after ultrasonic dispersion; wherein, the calcium oxide magnesium microcrystalline particles are mixed with magnesium oxide and calcium oxide, and mixed in the air It is obtained by roasting at 1600°C under atmosphere; 2+ with Mg 2+ The molar ratio of the calcium oxide is 0.01:1. The particle size of calcium oxide and magnesium crystals is determined by Hitachi S4800 field emission scanning electron microscope and Mastersizer2000 laser particle size measuring in...

Embodiment 2

[0068] Preparation of coating solution A: Weigh 2.38g of magnesium chloride, dissolve it in 62.5mL of absolute ethanol, stir and dissolve fully, then add 1.5g of glacial acetic acid and polyethylene glycol octylphenyl ether (the amount is 100% of the magnesium salt quality). %), mixed evenly, stirred and aged for 36h to obtain coating solution A;

[0069] Preparation of coating liquid B: take 10 g of the above coating liquid A, add 0.1 g of calcium oxide magnesium microcrystalline particles, and obtain coating liquid B after ultrasonic dispersion; the preparation method of the calcium oxide magnesium microcrystalline particles is: use 30-50 nm High-purity magnesium oxide microcrystalline particles are directly mixed with calcium oxide. After fully mixed, nano-sized magnesium oxide microcrystals are uniformly attached to the outer surface of calcium oxide particles, and calcined at 1200°C in an oxygen atmosphere to obtain calcium oxide magnesium microcrystalline particles; among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com