Ternary positive electrode material of high-capacity lithium ion battery and preparation method thereof

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, electrical components, secondary batteries, etc., can solve the problems that the increase in material capacity is difficult to meet the demand, the particle size deviation is large, and the mixing of raw materials is uneven, etc., to achieve Eliminate large amounts of wastewater discharge, reduce loss, and facilitate industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Add the stoichiometric ratio of nickel nitrate, cobalt nitrate and manganese nitrate (the molar ratio of nickel salt: cobalt salt: manganese salt is 3:3:14) into deionized water to dissolve, and prepare a solution with a concentration of 0.5 mol / L , And add maltodextrin to it (additional amount is 50% of the mass of LiOH used) to obtain solution c; meanwhile, weigh an appropriate amount of oxalic acid to prepare solution b with a concentration of 0.5 mol / L, and weigh the chemical solution under continuous stirring. The metered ratio of lithium hydroxide (5% excess) was added to solution b, and solution b was slowly added to solution c under stirring to obtain a slurry of nickel, cobalt, manganese and lithium. Continue stirring for 24 hours at room temperature, and then Spray drying in a spray dryer, the inlet temperature and outlet temperature of the spray dryer are 180°C and 70°C, respectively, to obtain the precursor powder. Then the precursor powder was calcined in a ...

Embodiment 2

[0036] Add the stoichiometric ratio of nickel nitrate, cobalt nitrate and manganese nitrate to deionized water to dissolve, prepare a solution a with a concentration of 5 mol / L, and add polyethylene glycol to it (additional amount is 10% of the mass of lithium compound ) To obtain solution c, and at the same time, weigh an appropriate amount of ammonium carbonate and prepare solution b with a concentration of 5 mol / L. Under continuous stirring, slowly add solution b to solution c, weigh the stoichiometric ratio of lithium hydroxide (5% excess) to prepare a small amount of solution, and add it to the above solution to obtain a slurry, and let it stand at room temperature After aging for 24 hours, the slurry is spray-dried to obtain precursor powder. The inlet air temperature of the spray dryer is 200°C and the outlet temperature is 80°C. Then, the precursor powder is calcined in a muffle furnace at 700°C for 5 hours, cooled naturally to room temperature, and finally ground to ob...

Embodiment 3

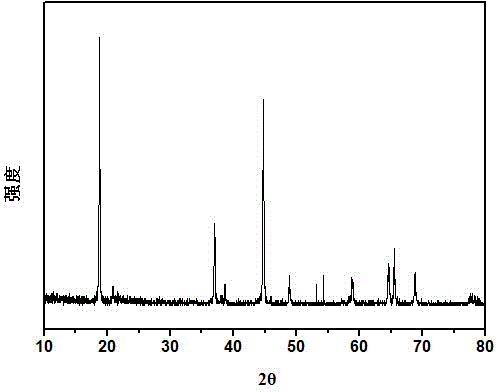

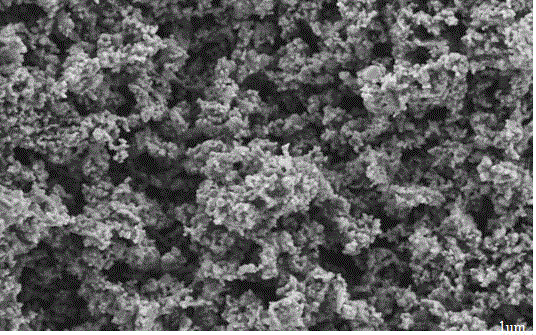

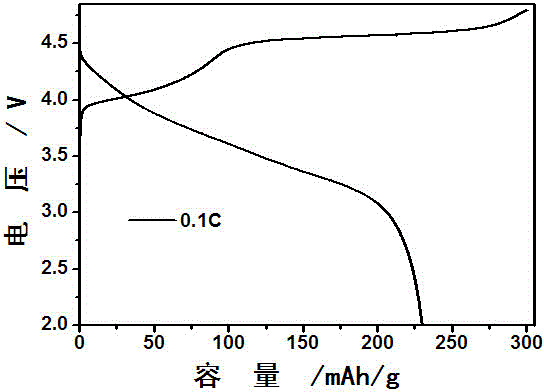

[0038] Add stoichiometric ratio of nickel acetate, cobalt acetate, and manganese nitrate to deionized water to dissolve, prepare solution a with a concentration of 0.5 mol / L, and add polyethylene glycol to it (additional amount is 25% of the mass of lithium compound ) To obtain solution c. At the same time, weigh an appropriate amount of ammonium carbonate to prepare a solution with a concentration of 0.5 mol / L. After stirring to dissolve, add stoichiometric lithium hydroxide (5% excess) to obtain solution b. Under continuous stirring, the solution b is slowly added to the solution c to obtain a slurry containing nickel, manganese, cobalt and lithium, and stirring is continued for 24 hours at room temperature, and then spray-dried to obtain a precursor powder. Then the precursor powder is calcined in a muffle furnace at 950℃ for 24 h, cooled naturally to room temperature, and finally ground to obtain the cathode material Li 1.5 Ni 0.25 Co 0.25 Mn 0.5 O 2 (The XRD spectrum and sc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com