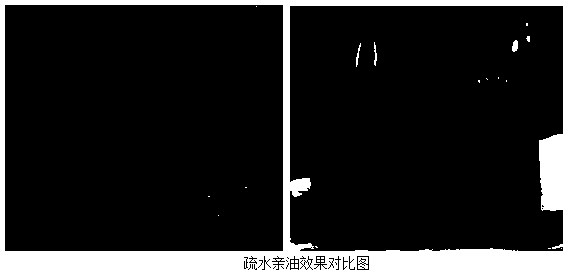

Sponge material with polyurethane sponge surface modified by constructing zinc oxide fine structure, and preparation method thereof

A polyurethane sponge and microstructure technology, applied in chemical instruments and methods, separation methods, liquid separation, etc., can solve the problems of oil can not be recycled, time-consuming, secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment one: the specific processing method of the zinc oxide microstructure described in the sponge surface structure is as follows:

[0033] 1) Preparation of ZnO nano-seeds. The main method is to prepare 25ml of 0.05mol / L zinc acetate alcoholic solution at 60~65℃, add an appropriate amount of 0.10mol / L ammonia water alcoholic solution drop by drop under constant stirring until a transparent zinc oxide seed solution is formed, and then continue After stirring for 2 hours, a colloidal solution of zinc oxide was obtained, with a weak Tyndall phenomenon.

[0034] 2) Coating process. The sponge that is about to be cleaned (cleaned by deionized water and ethanol ultrasonically) is immersed in the zinc oxide nanocrystal solution prepared above for 2~3min, then gently squeeze the sponge with a clean glass rod, and put it in an oven at 80~85℃ Dry for 5 minutes, and then put it into an oven at 170°C for 3 to 5 minutes to cure. The same process is repeated 3 times to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com